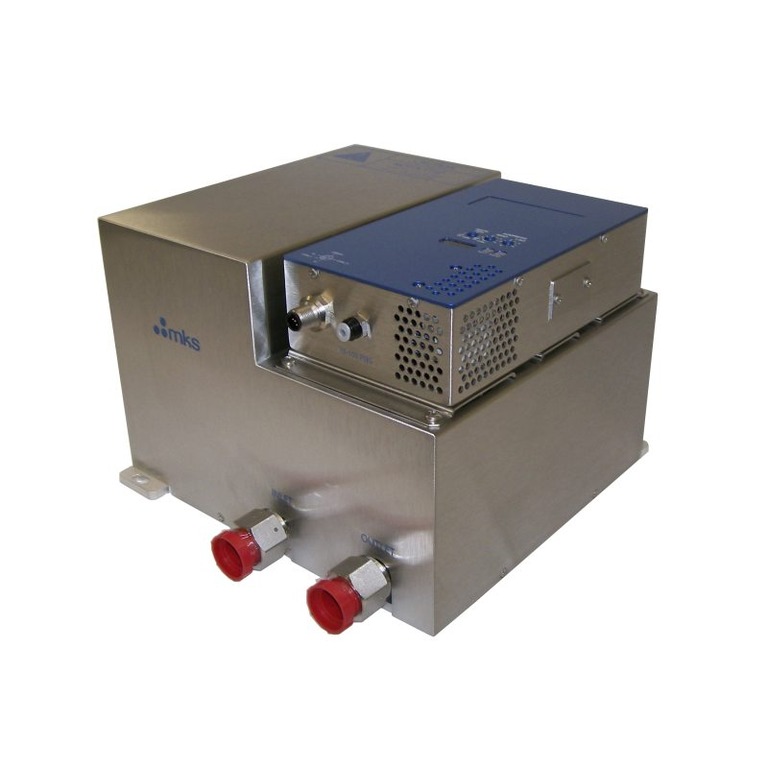

Επαληθευτής Ροής Μάζας

Ο HA-MFV της MKS είναι ενας επαληθευτής ροής μάζας υψηλής ακρίβειας, σχεδιασμένος για in-situ έλεγχο των ρυθμών ροής (flow rates) σε εργαλεία παραγωγικής διαδικασίας (process tools).

Mass Flow Verifier

Enables “Wafer-to-Wafer” “Chamber-to-Chamber” & “Tool-to-Tool” Matching

The HA-MFV, High Accuracy Mass Flow Verifier, is designed for in-situ verification of mass flow controller (MFC) flow rates directly on process tools. With 1.0% measurement accuracy and EtherCAT® or DeviceNet™ communications, it provides superior performance over traditional rate-of-rise methods by using the actual process gas.

➡️ 1.0% accuracy for wafer-to-wafer, chamber-to-chamber, and tool-to-tool process matching

➡️ Supports multiple gas panels to reduce implementation costs

➡️ 5 to 3000 sccm measurement range for a wide variety of processes

➡️ In-situ assessment of MFC flow rate improves process control and avoids unneeded down-time

Features

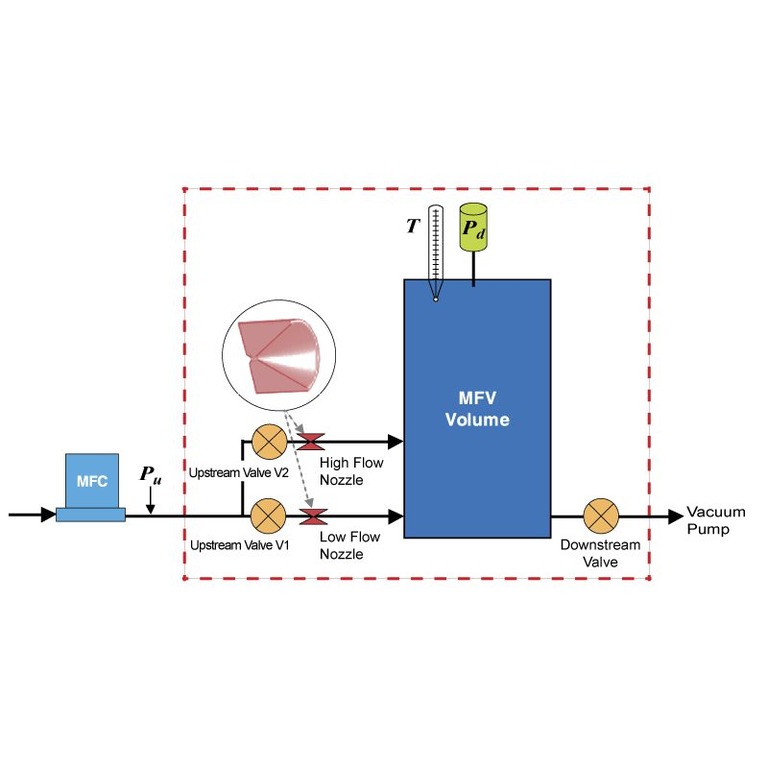

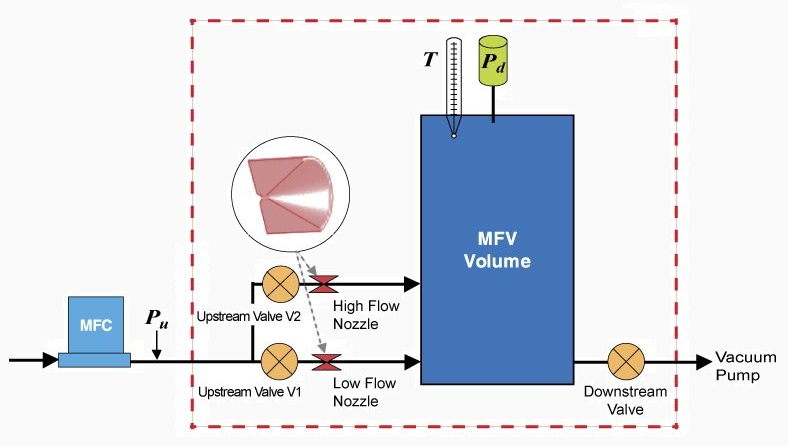

Sonic Flow Technology

The insensitivity of the HA-MFV to external volume is achieved through the use of sonic nozzle technology. The sonic nozzle creates a pressure drop and establishes sonic flow conditions, where downstream pressure variations do not affect upstream flow. As a result, the sonic nozzle effectively decouples the measurement in the HA-MFV from the upstream volume, ensuring accurate and stable readings.

Better Measurement Accuracy

The HA-MFV delivers significantly better measurement accuracy and is insensitive to external volume (i.e., the volume from the MFC to the HA-MFV). This volume insensitivity enables more precise matching of measurements between HA-MFVs across multiple tools running the same process, ensuring accurate tool-to-tool process matching for consistent and repeatable results.