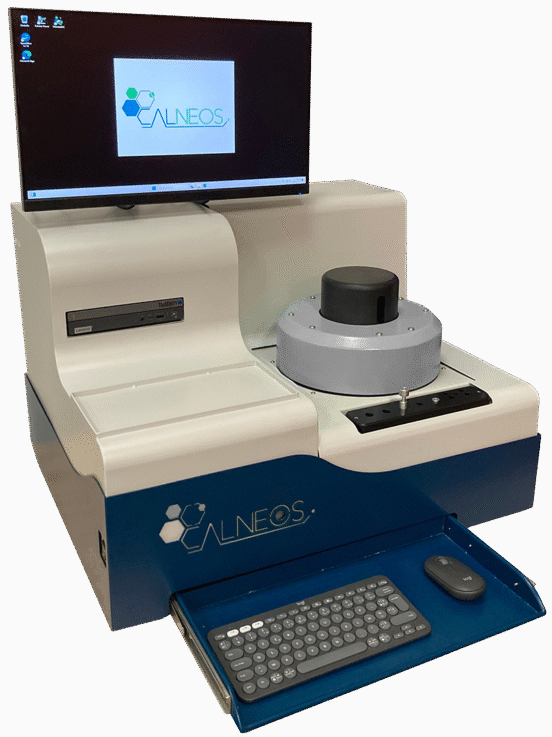

DSC L92 – Micro Calorimeter

Εξαιρετικά ευαίσθητο μικρο-θερμιδόμετρο που προσφέρει κορυφαία ακρίβεια στη θερμική ανάλυση, χάρη στον μοναδικό αισθητήρα του και τη βαθμονόμηση Joule.

Differential Scanning Calorimeter

DSC L92 – Micro Calorimeter

Ultra-sensitive micro calorimeter for precise thermal analysis of solids, liquids and solutions.

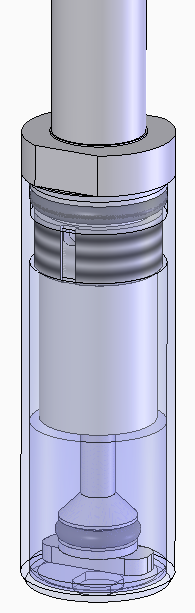

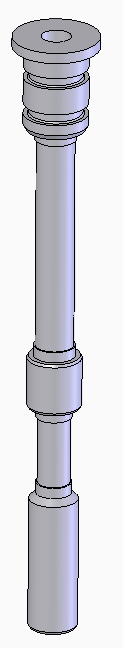

The DSC L92 from Calneos by Linseis is an ultra-sensitive micro calorimeter designed to deliver the highest precision in thermal analysis. With its unique sensor design, direct sample temperature measurement, and Joule effect calibration, it provides unrivalled accuracy for studying solids, liquids and even highly dilute solutions.

Equipped with interchangeable measurement cells, the system covers a broad range of applications. Batch and high-pressure Cp cells allow highly accurate heat capacity determinations, while bi-compartment and continuous flow cells enable advanced studies of chemical reactions, mixing enthalpies and gas dissolution processes under pressures up to 100 bar. This flexibility makes the DSC L92 a powerful tool for both routine measurements and specialized research tasks.

The instrument operates within a temperature range from -60 °C to 170 °C, with scan rates from 0.001 to 5 °C/min and a temperature regulation precision of 100 µ°C. Its exceptional low-noise performance (0.05 μW RMS) ensures that even the weakest transitions can be detected and analyzed with confidence.

Applications include detailed heat capacity studies, melting and crystallization analysis, detection of liquid-liquid phase transitions such as demixing or degassing, and the characterization of polymers like PTFE. Thanks to its compact footprint and innovative design, the DSC L92 combines high performance with ease of use, providing researchers with a reliable and versatile calorimetric solution.

Whether you are exploring phase transitions, studying reaction enthalpies, or analyzing gas-laden solutions under pressure, the DSC L92 delivers the sensitivity and flexibility required to push the boundaries of thermal analysis.

Unique Features

☑️ Ultra-high sensitivity

Direct sample temperature measurement with Peltier sensors and Joule effect calibration – enabling the detection of even the weakest thermal events.

☑️ Exceptional precision

Temperature regulation with 100 µ°C precision and extremely low RMS noise (0.05 μW), ensuring unrivalled measurement accuracy.

☑️ Wide application flexibility

Multiple interchangeable measurement cells (batch, high-pressure, bi-compartment, continuous flow) for solids, liquids, solutions and chemical reactions – including studies under pressures up to 100 bar.

☑️ Broad measurement range

Temperature range from -60 °C to 170 °C, scan rates from 0.001 to 5 °C/min, and measurement range of ±150 mW.

☑️ Compact and versatile design

Space-efficient instrument (700 × 650 × 500 mm) that integrates advanced functionality into a robust, easy-to-use system.

☑️ Comprehensive research applications

Ideal for studying heat capacities, melting and crystallization, phase transitions (e.g., demixing, degassing), polymer behavior and enthalpy of reactions.

☑️ Fast measurement cycles

Typical measurement times between 30–60 minutes, allowing efficient workflows.

☑️ Direct T-sample measurement

Unlike conventional systems, the DSC L92 measures the sample temperature directly, ensuring maximum accuracy.

☑️ Reusable measurement cells

Many cell types are reusable, reducing running costs and improving sustainability in long-term research.

Available Cells DSC L92

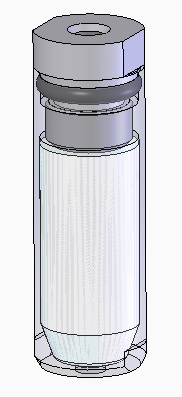

1. Batch cells

These cells can be used to study solids and liquids. They are the best for

precise heat capacities measurements (better than 3%) of and they are

reusables.

They can also be used to study transitions (melting/crystallisation) and

liquid-solid or liquid-liquid phase diagrams.

Useful volume: 850 μl

Pressure: a few bars

2. High pressure cells

They are identical to batch cells, with a pressurization tube to control pressure using the appropriate pressurization system.

Useful volume: Up to 330 µl (pressure dependent)

Pressure: Up to 1000 bars

3. Liquid Cp cells – High pressure

These cells have been specifically developed to measure the heat capacity of liquids under pressure. Their unique design makes them easy to fill completely and clean. Measurements are carried out in constant volume and the cells are installed in the instrument for the entire measurement campaign. They do not need to be removed to change the liquid being measured, which means that the Cp volume can be measured with an accuracy of better than 1%.

These cells can be used to observe very weak liquid-liquid transitions such as „demixing“ or „degassing“. They can be used at atmospheric pressure or under a few bars and have been tested up to 100 bars. With the right equipment, these cells can also be filled under pressure.

They can therefore be used to analyse gas-laden solutions under pressure.

Useful volume: 750 μL

Pressure: 100 bar

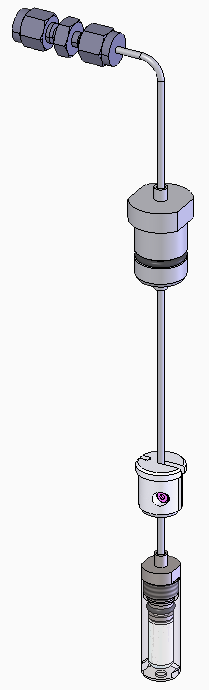

4. BI-Compartment cells

These cells enable enthalpy of reaction measurements to be made by limiting the Cp effect of the injection. A liquid is loaded into the upper compartment and injected into the lower compartment (solid or liquid).

Useful volumes: 150 + 250μL (other volumes on request)

Pressure: A few bars

6. ITC cell

UMC can be equipped with titration cells (1 ml) and with a suitable injection system (250 µl or 500 µl syringes). Injections are performed in both sample and reference cells to minimize the need for a “control experiment.”

This would enable isothermal titration calorimetry tests to be performed and interactions to be investigated. Accessible binding parameters are:

Binding constant (K): Indicates how strong the binding is.

Enthalpy change (ΔH): Indicates whether the binding is exothermic or endothermic.

Entropy change (ΔS): Provides information about changes in order in the system.

Free energy (ΔG): The combined thermodynamic expression of the binding

Stoichiometry parameter (n): How many ligands bind per target molecule

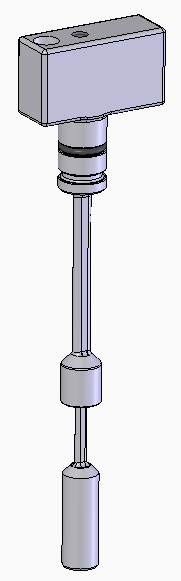

7. Customized Cells

If none of the above cells is suitable for your application, customized cells are also available on request.

Application

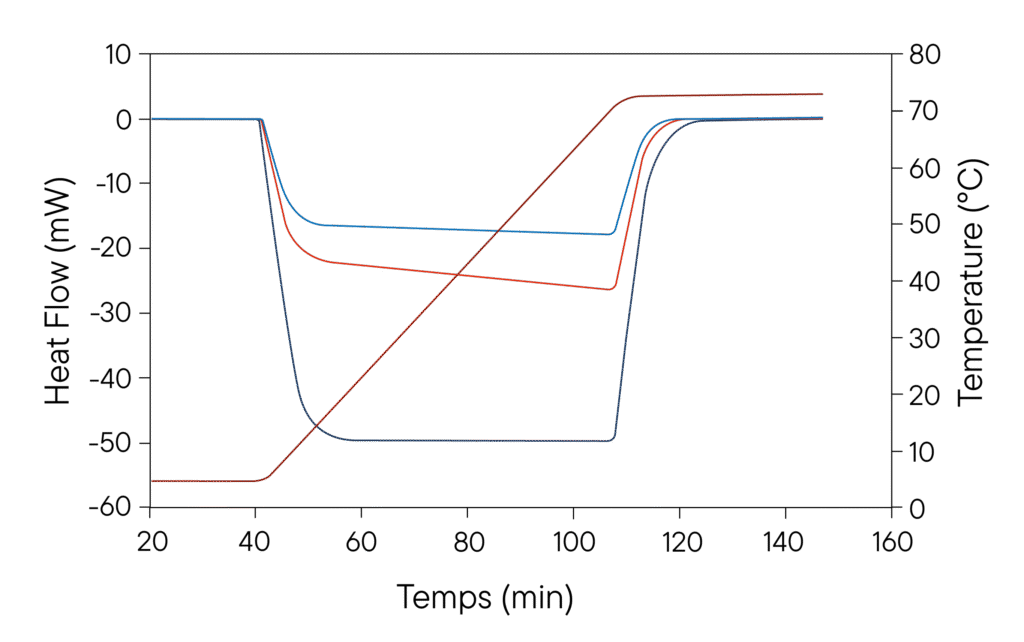

Application example: Measurement of the volumetric heat capacity by volume of fluids under controlled pressure

The volume vessel is filled by injecting approximately 3 mL of the liquid sample to be analysed with a syringe. This volume fills the useful volume of the vessel (0.7 mL) and the filling tubes. A slight counter-pressure is applied to the sample at the inlet (around 2 bar) to hold it during measurement and allows the sample to expand during the heating ramp. The Ultimate Micro Calorimeter was programmed as follows: a 40-minute isotherm at 5°C, followed by a heating ramp between 5°C and 73°C at 1°C/minute, and another 40-minute isotherm at 73°C. A total of 4 experiments of less than 2.5 hours were carried out: with water, absolute ethanol, cyclohexane, and a blank experiment that was subtracted from the other thermograms. The thermograms obtained are shown below.

The heat flow measured is proportional to the volumetric heat capacity of the fluid analysed. Simple mathematical processing of the signal obtained enables the calculation of the volumetric heat capacity.

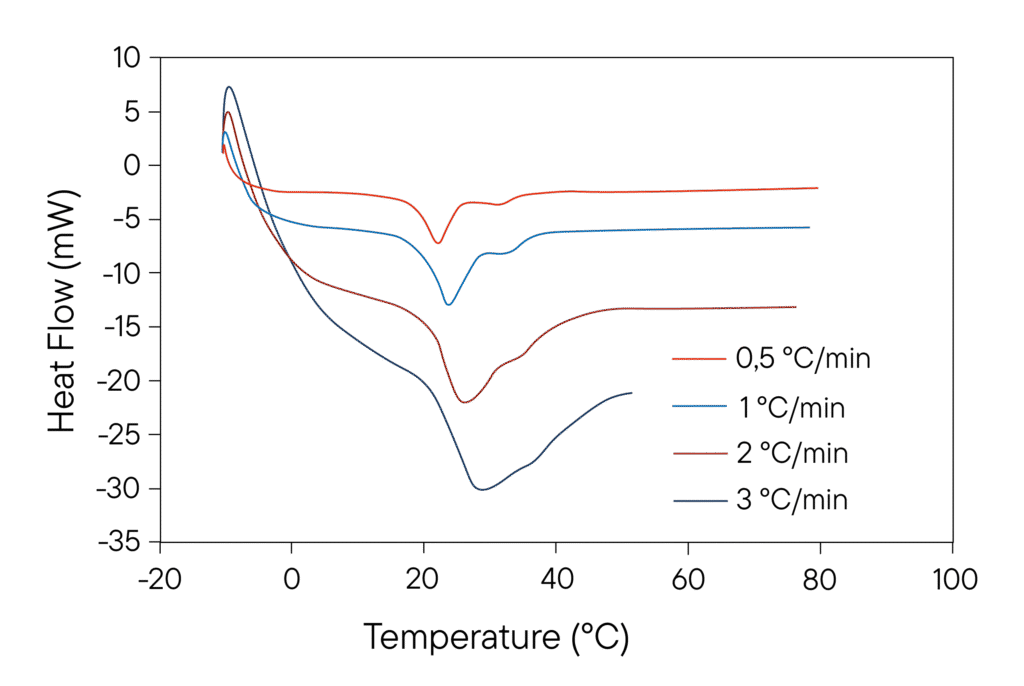

Application example: Phase transitions in PTFE close to ambient temperature

A 524 mg PTFE cylinder was placed in the measurement cell while the reference cell remained empty. The Ultimate Micro Calorimeter was programmed to perform several heating ramps between -10°C and 80°C, at scanning rate of between 0.5 and 3°C/minute. The thermograms obtained are shown here after. At all the rates, the two Teflon phase transitions were observed. The separation of the two transitions is better on the thermograms with the low scan rate.

The Ultimate Micro Calorimeter is an effective tool for studying phase transitions in materials. Its high sensitivity makes it easy to study very low-energy phenomena.