Linseis – Μετρητής Θερμικής Αγωγιμότητας (Thermal Conductivity Meter – HFM)

Ο μετρητής ροής θερμότητας LINSEIS HFM, είναι ένα εύχρηστο όργανο για τον προσδιορισμό της θερμικής αγωγιμότητας μονωτικών υλικών με χαμηλή θερμική αγωγιμότητα και άλλων υλικών.

✔️Παρέχει γρήγορα αποτελέσματα με υψηλή ακρίβεια.

✔️Χάρη στον μοναδικό σχεδιασμό του, οι μετρήσεις μπορούν να πραγματοποιηθούν σε λίγα μόνο λεπτά.

Heat Flow Meter (HFM)

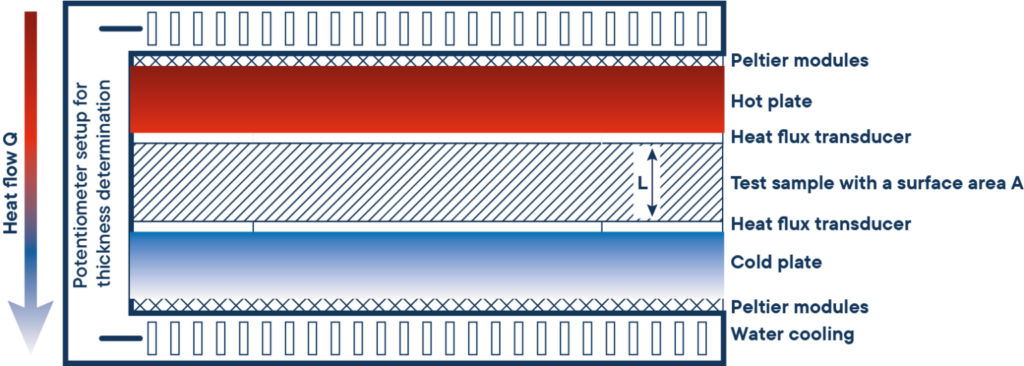

Peltier heating and cooling technology enables high-precision temperature control while reducing maintenance and downtime.

The excellent long-term stability enables accurate long-term aging studies.

Fast measurement cycles of only 15 minutes can be achieved, resulting in a high sampling rate.

To enable these fast and accurate sampling intervals, the device uses a dual sensor arrangement.

Built-in potentiometers for length measurements (μm resolution) provide instant sample thickness data.

HFM features of the “updated version”:

✔️Clean system design with improved insulation and optimized electronics

✔️Unrivaled precision and accuracy

✔️Low power consumption

✔️Design of the instrument based on the standards ASTM C518, JIS A1412, ISO 8301, DIN EN 12664 and DIN 12667

Most important advantages

Operating the device

The heat transfer coefficient can be calculated from the measured values of the heat flow through the sample divided by the cross-sectional area and the applied temperature difference. For a homogeneous material, the thermal conductivity lambda is the product of the U-value and the sample thickness.

Fourier’s law of heat conduction is the basis for calculating thermal conductivity and thermal resistance.

Downloads

ΙΔΑΝΙΚΟ ΓΙΑ

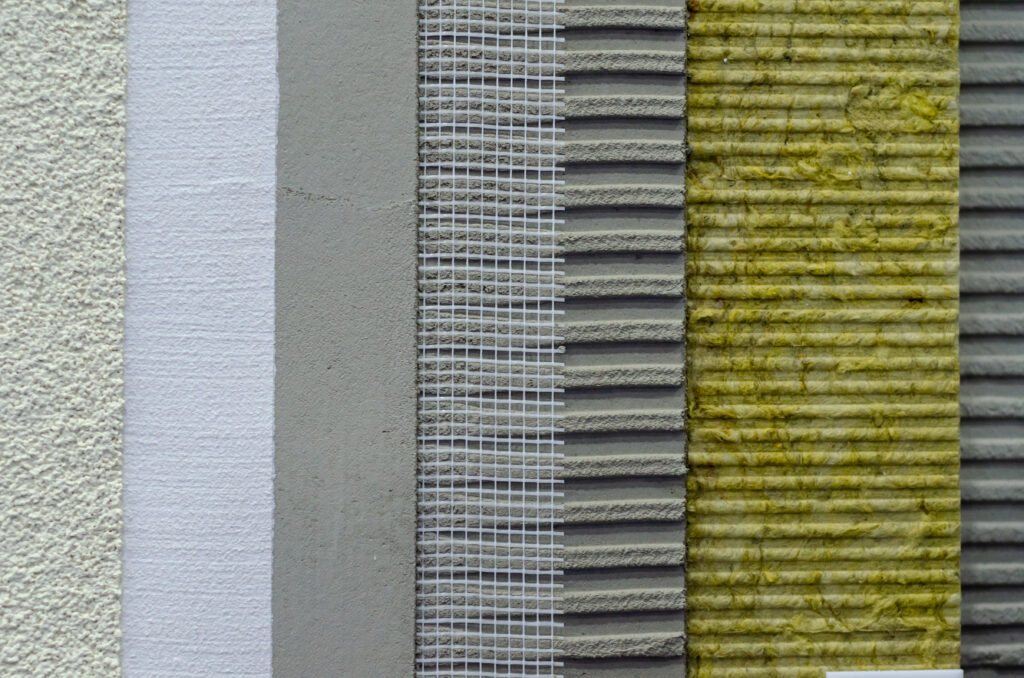

The LINSEIS Heat Flow Meter is ideal for the precise measurement of thermal conductivity and thermal resistance of materials. It is widely used for quality control, R&D, and material testing in industries like construction, automotive, aerospace, and electronics.

Key Applications:

- Thermal Conductivity Testing:

- Measures how well a material conducts heat, critical for insulation materials, polymers, ceramics, and more.

- Insulation Material Testing:

- Ensures materials meet energy efficiency and regulatory standards.

- Material Comparison:

- Helps compare the thermal properties of different materials for product development and optimization.

- Research and Development:

- Used in laboratories for developing advanced materials with specific thermal properties.

- Standard Compliance:

- The device meets international standards like ISO 8301 and ASTM C518, making it reliable for certification purposes.

ΧΑΡΑΚΤΗΡΙΣΤΙΚΑ

| MODEL | HFM 200 |

| Temperature range (plates): | 0°C to 90°C -20°C up to 90°C -35°C up to 90°C |

| Cooler: | External cooler or thermostat |

| Temperature control (plate): | Peltier |

| Temperature resolution: | 0.0001 °C |

| Measurement data points: | up to 100 |

| Sample size: | 200 mm x 200 mm, up to 90 mm thickness |

| Thermal resistance measuring range: | 0.2 to 8.0 m2∙K/W with extension set: 0.036 to 9.0 m2∙K/W |

| Measuring range thermal conductivity: | 0.001 to 0.5 W/m∙K, with extension set: 0.001 to 2.5 W/m∙K |

| Reproducibility: | 0.25% / 0,5 % |

| Accuracy: | +/- 1 up to 2 % |

| Variable contact pressure: | up to 1.3 kPa, optionally up to 25 kPa |

| Thermal conductivity: | 0.001 up to 0.5 W/m∙K, with extension set: 0.001 up to 2.2 W/m∙K |

| MODEL | HFM 300 |

| Temperature range (plates): | 0°C to 90°C -20°C up to 90°C -35°C up to 90°C |

| Cooler: | External cooler or thermostat |

| Temperature control (plate): | Peltier |

| Temperature resolution: | 0.0001 °C |

| Measurement data points: | up to 100 |

| Sample size: | 300 mm x 300 mm, up to 100 mm thickness |

| Thermal resistance measuring range: | 0.2 to 8.0 m2∙K/W, with extension kit: 0.036 to 8.0 m2∙K/W |

| Measuring range thermal conductivity: | 0.001 to 0.5 W/m∙K, with extension kit: 0.001 to 2.5 W/m∙K |

| Reproducibility: | 0.25% / 0,5 % |

| Accuracy: | +/- 1 up to 2 % |

| Variable contact pressure: | up to 1.3 kPa, optionally up to 25 kPa |

| Thermal conductivity: | 0.001 up to 0.5 W/m∙K, with extension set: 0.001 up to 2.5 W/m∙K |

| MODEL | HFM 600 |

| Temperature range (plates): | -20 to 70°C – – |

| Cooler: | External cooler or thermostat |

| Temperature control (plate): | Peltier |

| Temperature resolution: | 0.0001 °C |

| Measurement data points: | up to 100 |

| Sample size: | 600 mm x 600 mm, up to 200 mm thickness |

| Thermal resistance measuring range: | 0.2 to 8.0 m2∙K/W, with extension kit: 0.036 to 8.0 m2∙K/W |

| Measuring range thermal conductivity: | 0.001 to 0.5 W/m∙K |

| Reproducibility: | 0.25% / 0,5 % |

| Accuracy: | +/- 1 up to 2 % |

| Variable contact pressure: | up to 1.3 kPa, optionally up to 25 kPa |

| Thermal conductivity: | 0.001 up to 0.5 W/m∙K, with extension set: 0.001 up to 2.5 W/m∙K |