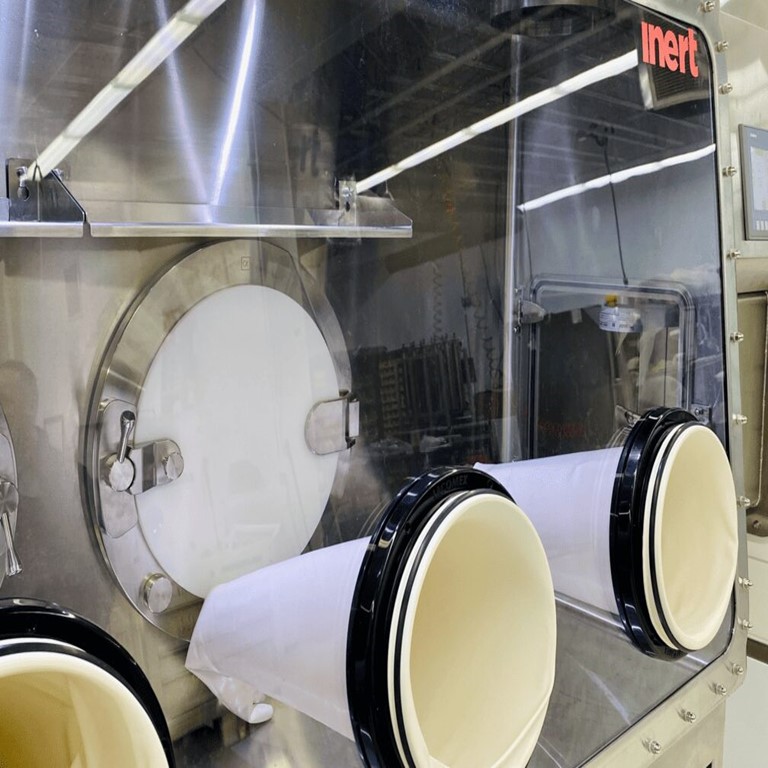

SafeLab – Gloveboxes Αρνητικής Πίεσης

Η σειρά SafeLab της Inert, περιλαμβάνει θαλάμους αδρανούς ατμόσφαιρας αρνητικής πίεσης, σχεδιασμένους για την προστασία του χρήστη κατά τη διάρκεια χειρισμών με μολυσματικές ουσίες ή επικίνδυνα υλικά. Ειδικά σχεδιασμένοι για τοξικές, φαρμακευτικές ή πυρηνικές εφαρμογές.

SafeLab

Negative pressure filtered air glovebox

Negative pressure gloveboxes are designed for user protection during manipulation of contaminants or hazardous materials. Specifically designed for toxic, pharmaceutical, or nuclear applications.

INERT’s expertise in leak-tight enclosures enables the delivery of ISO 10648-2 certified gloveboxes, meeting a leak rate of < 0.05% Vol/h. These systems can be tailored with a wide range of custom options and features to meet specific application requirements.

➤ Protection type: operator protection

➤ Industries: Nuclear, Pharma

🟥 Stainless steel 304, 304L, or 316L

🟥 Round Corner fabrication

🟥 Brush finish #4

🟥 Push-Through or BiBo filter exchange

🟥 Ventilated or static antechamber

🟥 HEPA H13, H14, or ULPA

🟥 LED lighting

🟥 ISO 10648-2 leak test certified

Safety Features

🟥 Patented VMR Regulation Valve for air flow regulation and operator safety

🟥 Automatic isolation valves in case of power loss or air flow loss

🟥 Alarms and beacon for enhanced safety monitoring

🟥 Bag-In Bag-Out (BiBo)

The Bag-In Bag-Out (BiBo) method offers a secure, contamination-free process for replacing HEPA filters. Each filter is enclosed in an individual stainless steel module, typically positioned outside the main glovebox. The BiBo filter module dimensions are adapted to match the HEPA filter size and the required flow rating.

🟥 Safety Valves

VMR and VMS valves are designed to ensure user protection in the event of a containment breach within the enclosure. Engineered to protect the operator under all circumstances, these valves are installed on negative pressure gloveboxes operating with either an inert atmosphere or filtered air.

🟥 Filter Housing

The Push-Through (Push-Push)method is anefficient HEPA filter replacement technique, specifically designed for applications with high containment requirements. By integrating these advanced HEPA filter exchange systems, INERT ensures maximum containment, operator protection, and operational efficiency for critical applications.

Size & Dimensions

| Model | Width | Depth | Height |

|---|---|---|---|

| SafeLab 2GB | 49.2″ (1250 mm) | 26.7″ (680 mm) | 35.4″ (900 mm) |

| SafeLab 3GB | 59″ (1500 mm) | 26.7″ (680 mm) | 35.4″ (900 mm) |

| SafeLab 4GB | 70.9″ (1800 mm) | 26.7″ (680 mm) | 35.4″ (900 mm) |

Accessories

🟥 High purity coatings – fluoropolymers

🟥 Air conditioning unit

🟥 Lead glass shielded windows

🟥 Filter integrity test ports

🟥 Delta pressure monitoring

🟥 RTP / DPTE ports

🟥 Continuous liner, waste ports

🟥 Interface with fume hood