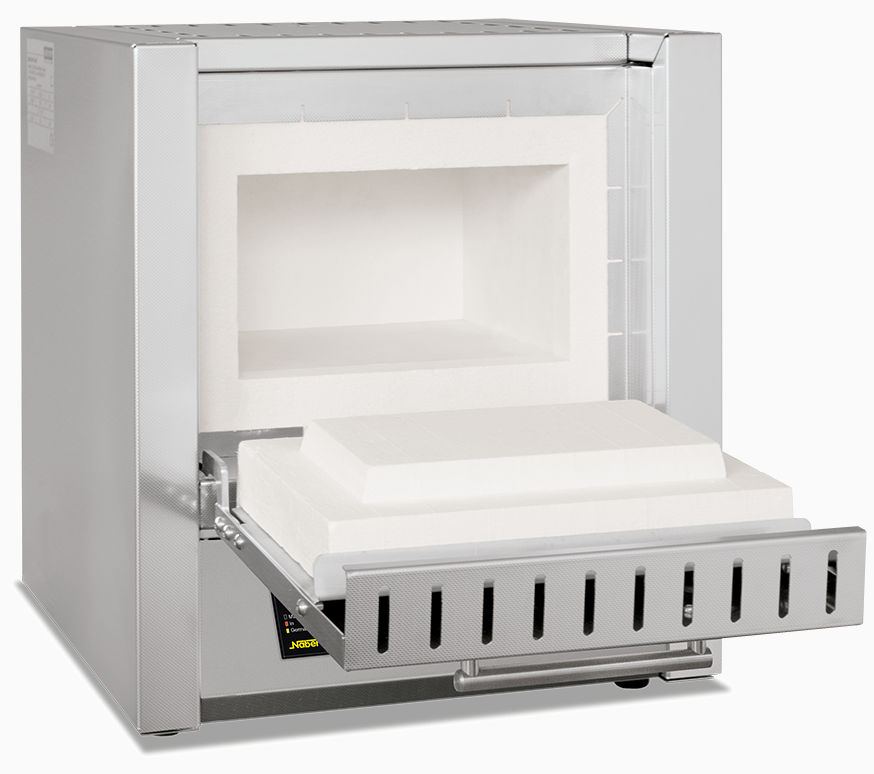

The Muffle Furnaces up to 1400 °C category includes diverse models with varying temperature limits (from 1100 °C to 1400 °C), insulation types (fiber or brick), heating technologies (such as embedded elements in ceramic muffle), and special features like integrated exhaust gas cleaning or built-in scales and software for determining combustion loss, making them ideal for a wide range of laboratory applications.

Πυριαντήρια έως 1400 °C

Τα πυριαντήρια έως 1400 °C είναι υψηλής απόδοσης εργαστηριακές συσκευές, κατάλληλες για απαιτητικές εφαρμογές όπως θερμική κατεργασία, δοκιμές υλικών και αποτέφρωση, προσφέροντας εξαιρετική θερμική σταθερότητα, ανθεκτική μόνωση και ακριβή έλεγχο.

Category Πυριαντήρια

Brand: Nabertherm GmbH

Περιγραφή

Muffle Furnaces up to 1400 °C

Advanced Solutions for High-Temperature Processes up to 1400 °C

Muffle Furnaces up to 1100 °C or 1200 °C

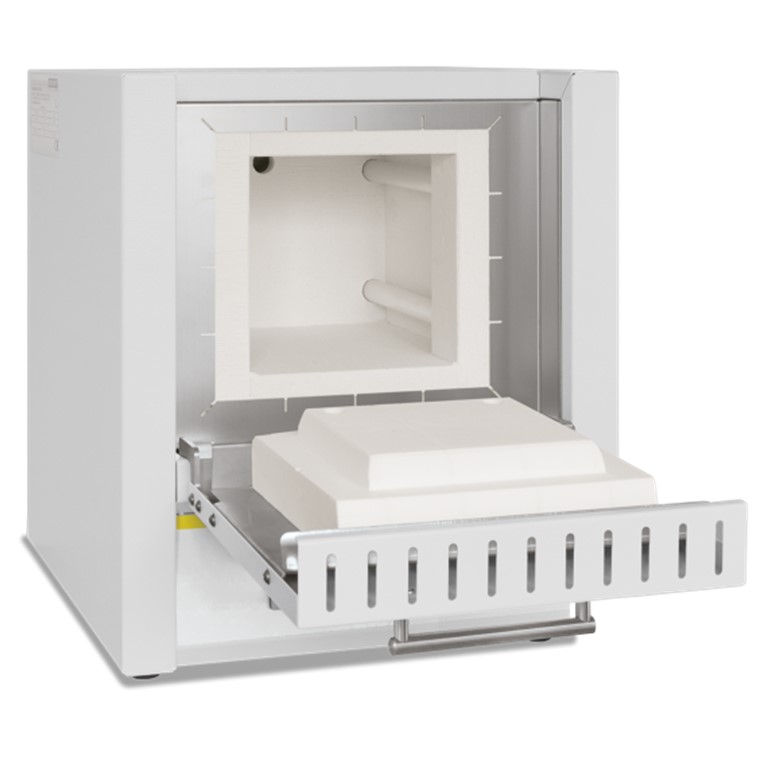

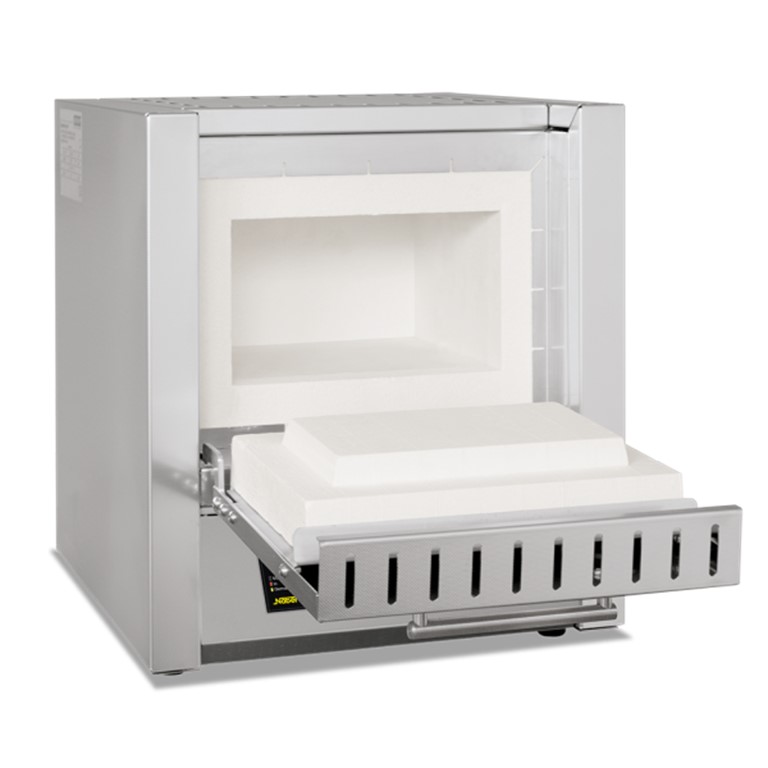

The muffle furnaces L 3/11 – LT 60/12 have been proven for daily laboratory use. These models stand out for their excellent workmanship, advanced and attractive design, and high level of reliability. The muffle furnaces come equipped with either a flap door or lift door at no extra charge.

🟨 Tmax 1100 °C or 1200 °C

🟨 Heating from 2 or 3 sides with ceramic heating plates for uniform temperature

🟨 Temperature uniformity ±5 K above 800 °C (DIN 17052-1)

🟨 Thermocouple type N or type S depending on model

🟨 Easy-to-replace heating elements integrated in ceramic plates

🟨 Flap door (L) or lift door (LT) option

🟨 Ventilated stainless steel housing for low surface temp and stability

🟨 No RCF insulation – safe, CLP-compliant materials only

🟨 Air inlet in door, exhaust outlet in rear wall

🟨 B510 or R8 controller with touch operation

🟨 Solid state relays for quiet operation

🟨 USB data logging with NTLog Basic

Economy Muffle Furnaces up to 1100 °C

With their convincing price/performance ratio and the fast heat-up rates, these compact muffle furnaces are perfect for many applications in the laboratory. Quality features like the dual shell furnace housing of rust-free stainless steel, their compact, lightweight constructions, or the heating elements encased in quartz glass tubes make these models reliable partners for your application.

🟨 Tmax 1100 °C

🟨 Heating from two sides with quartz glass-protected elements

🟨 Fast heating times

🟨 Easy maintenance of heating elements and insulation

🟨 RAL 9003-coated housing

🟨 Solid state relays for quiet operation

🟨 Dual shell stainless steel housing with fan cooling for low surface temperature

🟨 No RCF insulation – fully CLP-compliant materials

🟨 Flap door usable as work platform

🟨 Exhaust outlet at rear wall

🟨 Compact size and lightweight

🟨 Space-saving controller placement under door

🟨 Controller R8 (single temperature setting)

🟨 Defined application per operating instructions

Muffle Furnaces with Brick Insulation up to 1300 °C

Heating elements on support tubes radiating freely into the furnace chamber provide for particularly short heating times for these muffle furnaces. Thanks to their robust lightweight refractory brick insulation, they can reach a maximum working temperature of 1300 °C. These furnaces are an ideal alternative to the familiar L(T) ../12 models when a higher application temperature is required.

🟨 Tmax 1300 °C

🟨 Heating from two sides

🟨 Heating elements on support tubes for free heat radiation and long service life

🟨 Multi-layer insulation with lightweight refractory bricks

🟨 Dual shell ventilated housing made of textured stainless steel for low surface temperature and high stability

🟨 Optional flap door (L) or lift door (LT) with hot surface facing away from the operator

🟨 Adjustable air inlet in door

🟨 Exhaust air outlet in rear wall

🟨 Controller B510 with touch operation (5 programs × 4 segments)

🟨 Solid state relays for quiet operation

🟨 Defined application per operating instructions

🟨 NTLog Basic for data recording via USB-flash drive

Muffle Furnaces up to 1400 °C

These models stand out for their excellent workmanship, advanced and attractive design, and high level of reliability. Heating elements on support tubes radiating freely into the furnace chamber provide for particularly short heating times and a maximum temperature of 1400 °C. These muffle furnaces are a good alternative to the familiar L(T) ../12 series when higher application temperatures are needed.

🟨 Tmax 1400 °C

🟨 Heating from two sides

🟨 Heating elements on support tubes for free heat radiation and long service life

🟨 Dual shell housing of textured stainless steel with fan cooling for low surface temperature

🟨 Insulation materials fully CLP-compliant (no hazardous classification)

🟨 Adjustable air inlet integrated in door

🟨 Exhaust air outlet in rear wall

🟨 Controller B510 with touch operation (5 programs × 4 segments)

🟨 Solid state relays for quiet operation

🟨 Defined application per operating instructions

🟨 NTLog Basic for process data recording via USB-flash drive

Muffle Furnaces with Embedded Heating Elements in the Ceramic Muffle up to 1100 °C

The muffle furnace L 9/11/SKM is recommended for heat treatment of aggressive substances. The furnace has a ceramic muffle with embedded heating from four sides. The muffle furnace thus combines very good temperature uniformity with excellent protection of the heating elements from aggressive atmospheres. Another aspect is the smooth, nearly particle-free muffle (furnace door made of fiber insulation), an important quality feature.

🟨 Tmax 1100 °C

🟨 Muffle heated from four sides

🟨 Embedded ceramic muffle with high resistance to aggressive gases and vapours

🟨 Dual shell housing made of textured stainless steel with fan cooling for low surface temperature

🟨 CLP-compliant insulation materials (no hazardous classification)

🟨 Optional flap door (L) or lift door (LT) with hot surface facing away from the operator

🟨 Adjustable air inlet in door

🟨 Exhaust air outlet in rear wall

🟨 Controller B510 with touch operation (5 programs × 4 segments)

🟨 Solid state relays for quiet operation

🟨 Defined application per operating instructions

🟨 NTLog Basic for USB data logging

Ashing Furnaces up to 1100 °C

Ashing furnace LV(T) .. 11 is designed especially for ashing processes up to 1050 °C in the laboratory. Applications include loss on ignition determination, and ashing of food and plastics for substance analysis. A special fresh-air and exhaust system replaces the air 6 times per minute, ensuring sufficient oxygen for effective ashing. The incoming air is pre-heated by the furnace heating, providing good temperature uniformity.

🟨 Tmax 1100 °C

🟨 Heating from two sides

🟨 Ceramic heating plates with integral heating elements, safeguarded and easy to replace

🟨 Air exchange >6 times/minute

🟨 Good temperature uniformity via preheated incoming air, ±10 °C (DIN 17052-1, from 550 °C)

🟨 Dual shell housing of textured stainless steel with fan cooling

🟨 CLP-compliant insulation materials only

🟨 Suitable for standardized ashing processes (ISO, ASTM, EN, DIN)

🟨 Optional flap door (LV) or lift door (LVT) with hot surface facing away from operator

🟨 Controller B510 with touch operation (5 programs × 4 segments)

🟨 Solid state relays for quiet operation

🟨 Defined application per operating instructions

🟨 NTLog Basic for USB data logging

Ashing Furnaces with Integrated Exhaust Gas Cleaning up to 1100 °C

The ashing furnaces L ../11 BO are specially designed for evaporation of organic substances, such as debinding of ceramic parts after additive manufacturing. They are also ideal for ashing food samples, thermal cleaning of tools, and loss on ignition determination.

These furnaces feature a passive safety system and integrated exhaust gas post combustion. An exhaust fan removes gases while supplying fresh oxygen-rich air, ensuring efficient combustion. The incoming air is preheated for uniform temperature, and exhaust gases are cleaned through a catalytic post-combustion system. After debinding or ashing (up to 600 °C), a sintering process up to 1100 °C can follow.

🟨 Tmax 600 °C for incineration process

🟨 Tmax 1100 °C for subsequent process

🟨 Three-side heating (both sides and bottom)

🟨 Ceramic heating plates with embedded heating wire

🟨 Dual shell ventilated housing made of textured stainless steel for low surface temperature and high stability

🟨 CLP-compliant insulation materials, no refractory ceramic fiber (RCF)

🟨 Steel collecting pan to protect bottom insulation

🟨 Spring-assisted flap door with mechanical locking

🟨 Thermal/catalytic post combustion, active up to 600 °C

🟨 Post combustion temperature control up to 850 °C

🟨 Monitored exhaust air

🟨 Preheated inlet air via bottom heating plate

🟨 Over-temperature limiter with adjustable cutout

🟨 Controller C550 with touch operation (10 programs × 20 segments)

🟨 Defined application per operating instructions

🟨 NTLog Basic for USB data logging

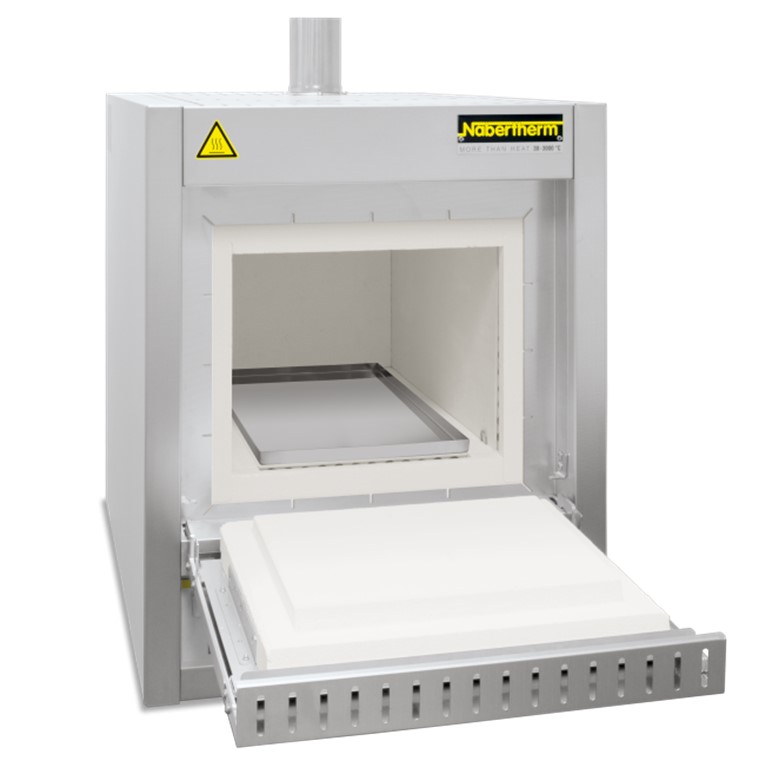

Muffle Furnace incl. Scale and Software for Determination of Combustion Loss

This weighing furnace with integrated precision scale and software is specially designed for combustion loss determination in the laboratory. It is ideal for analyzing sludges, household waste, and other materials requiring mass loss evaluation. The combustion loss is calculated as the difference between the total mass and the residue. During the process, the included software records both temperature and weight loss for accurate tracking.

🟨 Like muffle furnaces L(T), except:

🟨 Includes base, ceramic plunger with base plate, precision scale, and software package

🟨 4 scale options for different max weights and scaling ranges

🟨 Process control and documentation via VCD software for temperature and combustion loss monitoring

🟨 Controller B510 with 5 programs × 4 segments

ΠΑΡΟΜΟΙΑ ΠΡΟΪΟΝΤΑ

Οι μηχανικοί ομογενοποιητές IKA ULTRA-TURRAX προσφέρουν υψηλής απόδ…

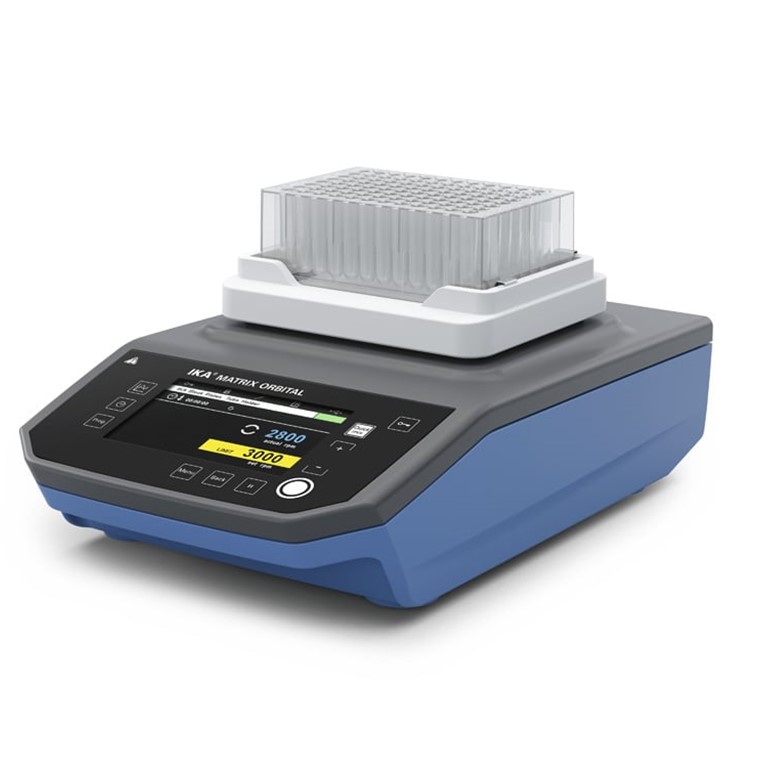

Οι θερμοανακινητήρες της IKA συνδυάζουν ανάδευση, θέρμανση και ψύξη σε μία…

Οι Ανακινητήρες Εργαστηρίου της IKA εξασφαλίζουν ακριβή και σταθερή κί�…

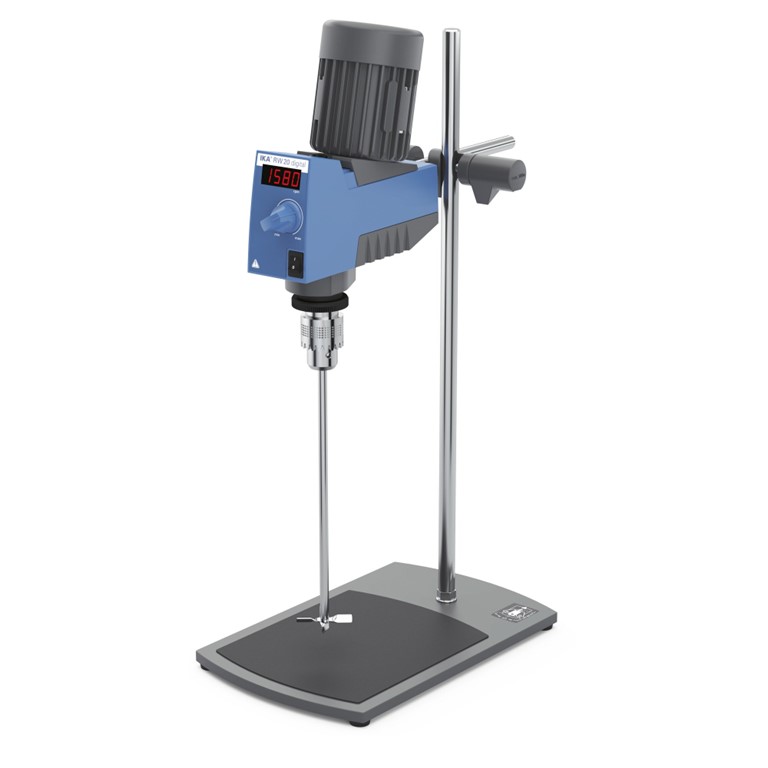

Οι Αναδευτήρες Overhead της IKA προσφέρουν αξιόπιστη και ισχυρή ανάδευση…

Οι μαγνητικοί αναδευτήρες της IKA προσφέρουν υψηλή ενεργειακή απόδοση,…

Οι κλίβανοι ξηρής αποστείρωσης TauSteril προσφέρουν αξιόπιστη και υψη…

Οι κλίβανοι αποστείρωσης της Astell Scientific διατίθενται σε μεγάλο εύ…

Υψηλής απόδοσης λύσεις αποθήκευσης για αίμα, δείγματα και φάρμακα, που κ…

Αυτόματο σύστημα για αναδιάταξη σωληναρίων, ζύγιση, ανίχνευση όγκου και �…

Υψηλής απόδοσης λύσεις σάρωσης για κρυογενικά φιαλίδια και ραφιά, που �…

Πολυκάναλη συσκευή για γρήγορο και εργονομικό άνοιγμα και κλείσιμο καπ…

Τα racks κατάψυξης έχουν σχεδιαστεί για οργανωμένη και αξιόπιστη απο�…