The Tube Furnaces up to 1800 °C category includes a wide range of models designed to meet diverse laboratory and industrial needs. Options range from compact furnaces up to 1100 °C and 1300 °C, to split-type and rotary furnaces for batch or continuous processes. Higher temperature models feature stand-mounted units up to 1500 °C, SiC rod heating for up to 1600 °C, and high-temperature furnaces reaching 1800 °C. Customized solutions are also available to fit specific requirements.

Σωληνωτοί Φούρνοι έως 1800 °C

Οι Σωληνωτοί Φούρνοι έως 1800 °C είναι ιδανικοί για εφαρμογές που απαιτούν ελεγχόμενη ατμόσφαιρα ή συνθήκες κενού. Προσφέρουν άριστη ομοιομορφία θερμοκρασίας, γρήγορη θέρμανση και μεγάλη ποικιλία από υλικά και διαμορφώσεις σωλήνων για εργαστηριακή και βιομηχανική χρήση.

Category Πυριαντήρια

Brand: Nabertherm GmbH

Περιγραφή

Tube Furnaces up to 1800 °C

Precision Heating in Controlled Atmospheres for Laboratory and Industrial Applications

Compact Tube Furnaces up to 1100 °C

The RD 30/200/11 tube furnace impresses with its very good price-performance ratio, particularly compact external dimensions and low weight. This all-rounder is equipped with a working tube, which also serves as support for the heating wires. The working tube is therefore part of the furnace heating, with the advantage that the tube furnace reaches very high heating speeds. The furnace is designed for horizontal use up to 1100 °C.

🟨 Tmax 1100 °C

🟨 Dual shell ventilated housing made of textured stainless steel for low surface temperature and high stability

🟨 CLP-compliant insulation materials, no refractory ceramic fiber (RCF)

🟨 Inner diameter 30 mm, heated length 200 mm

🟨 Ceramic working tube C 530 with two fiber plugs for operation under air

🟨 Thermocouple type K (1100 °C)

🟨 Solid state relays for low noise operation

🟨 Heating wires wound directly around working tube for fast heat-up rates

🟨 Defined application per operating instructions

🟨 Controller R8

Compact Tube Furnaces up to 1300 °C

These compact tube furnaces with integrated control systems can be used universally for many processes. Equipped with a standard C 530 ceramic working tube and two fiber plugs, these tube furnaces offer a very good price/performance ratio.

🟨 Tmax 1200 °C or 1300 °C

🟨 Single-zoned design

🟨 Dual shell ventilated housing made of textured stainless steel for low surface temperature and high stability

🟨 CLP-compliant insulation materials, no refractory ceramic fiber (RCF)

🟨 Outer tube diameter 50 mm to 170 mm, heated length 250 mm to 1000 mm

🟨 Ceramic working tube C 530 with two fiber plugs for operation under air

🟨 Thermocouple type N (1200 °C) or type S (1300 °C)

🟨 Solid state relays for low noise operation

🟨 Heating elements on support tubes for free radiation

🟨 Defined application per operating instructions

🟨 NTLog Basic for Nabertherm controller, data recording via USB-flash drive

🟨 Controller with touch operation B510 (5 programs × 4 segments)

Split-Type Tube Furnaces for Horizontal or Vertical Operation up to 1300 °C

These tube furnaces are suitable for horizontal (RSH) or vertical (RSV) operation. The split-type design allows for easy working tube exchange, accommodating tubes made of different materials. With a wide range of accessories, these professional furnaces can be tailored to your process, including protective gas atmospheres, gas usage, or vacuum conditions. Control options include standard controllers and advanced PLC controls for precise process management.

🟨 Tmax 1100 °C or 1300 °C

🟨 Single-zoned design

🟨 Dual shell ventilated housing made of textured stainless steel for low surface temperature and high stability

🟨 CLP-compliant insulation materials, no refractory ceramic fiber (RCF)

🟨 RSV models with frame for vertical operation

🟨 Split-type design for simple working tube insertion (opening temperature < 180 °C)

🟨 Ceramic working tube C 530 with two fiber plugs for operation under air

🟨 Thermocouple type N (1100 °C) or type S (1300 °C)

🟨 Solid state relays for low noise operation

🟨 Heating elements on support tubes for free radiation

🟨 RSH: switchgear and control unit integrated in furnace housing

🟨 RSH: controller with touch operation B510 (5 programs × 4 segments)

🟨 RSV: switchgear and control unit separate, in own wall or standing cabinet

🟨 RSV: controller with touch operation B500 (5 programs × 4 segments)

🟨 Defined application per operating instructions

🟨 NTLog Basic for Nabertherm controller, data recording via USB-flash drive

Rotary Tube Furnaces for Batch Operation up to 1100 °C

The rotary tube furnaces of the RSRB series are designed for batch operation. The rotating working tube keeps the charge in motion. The quartz reactor with tapered pipe ends retains the batch inside, allowing for extended heat treatment. They also support controlled heating to specific temperature profiles.

🟨 Tmax 1100 °C

🟨 Single-zoned design

🟨 Dual shell ventilated housing made of textured stainless steel for low surface temperature and high stability

🟨 CLP-compliant insulation materials, no refractory ceramic fiber (RCF)

🟨 Thermocouple type N

🟨 Solid state relays for low noise operation

🟨 Heating elements on support tubes for free radiation

🟨 Table-top model with quartz glass reactor opening both sides, tapered ends

🟨 Reactor removable for easy emptying

🟨 Beltless drive and hinged furnace housing (opening temperature < 180 °C) for easy removal

🟨 Adjustable drive speed approx. 1-40 rpm

🟨 Defined application within operating instructions

🟨 NTLog Basic for data recording via USB-flash drive

🟨 Controller with touch operation B510 (5 programs × 4 segments)

Rotary Tube Furnaces for Processes with Continuous Movement up to 1300 °C

The rotary tube furnaces of the RSRC series are particularly suitable for processes in which continuously running batch material is heated short-time. These rotary furnaces can be used very flexibly for various purposes. The rotary tube furnace is slightly inclined and brought to the target temperature. The material is then fed continuously at the top of the pipe. It passes through the heated zone of the tube and falls out of the pipe at the lower end. The time of the heat treatment depends on the angle of inclination, the speed of rotation and the length of the working tube, as well as from the flow properties of the batch material. Equipped with the optionally available closed feeding system, the rotary tube furnace can also be used for processes in a defined atmosphere or in a vacuum. Depending on the process, batch and required maximum temperature, work tubes made of different materials are used.

🟨 Tmax 1100 °C

➤Working tube made of quartz glass, open at both sides

➤Thermocouple type N

🟨 Tmax 1300 °C

➤Open ceramic tube C 530

➤Thermocouple type S

🟨 Solid state relays provide for low-noise operation

🟨 Heating elements on support tubes provide for free radiation

🟨 Dual shell ventilated housing made of textured stainless steel sheets for low surface temperature and high stability

🟨 Exclusive use of insulation materials without categorization according to EC Regulation No 1272/2008 (CLP). This explicitly means that alumino silicate wool, also known as “refractory ceramic fiber” (RCF), which is classified and possibly carcinogenic, is not used.

🟨 Adjustable drive of approx. 0.5–20 rpm

🟨 Digital display unit for the tilting angle of the rotary tube furnace

🟨 Split-type furnace housing (opening temperature < 180 °C) provides for easy tube change

🟨 Compact system, rotary tube furnace positioned on a base frame

➤Manual spindle drive with crank to set the tilting angle

➤Switchgear and controls integrated

➤Castors

🟨 Defined application within the constraints of the operating instructions

🟨 NTLog Basic for Nabertherm controller: recording of process data with USB flash drive

🟨 Controller with touch operation B500 (5 programs with each 4 segments)

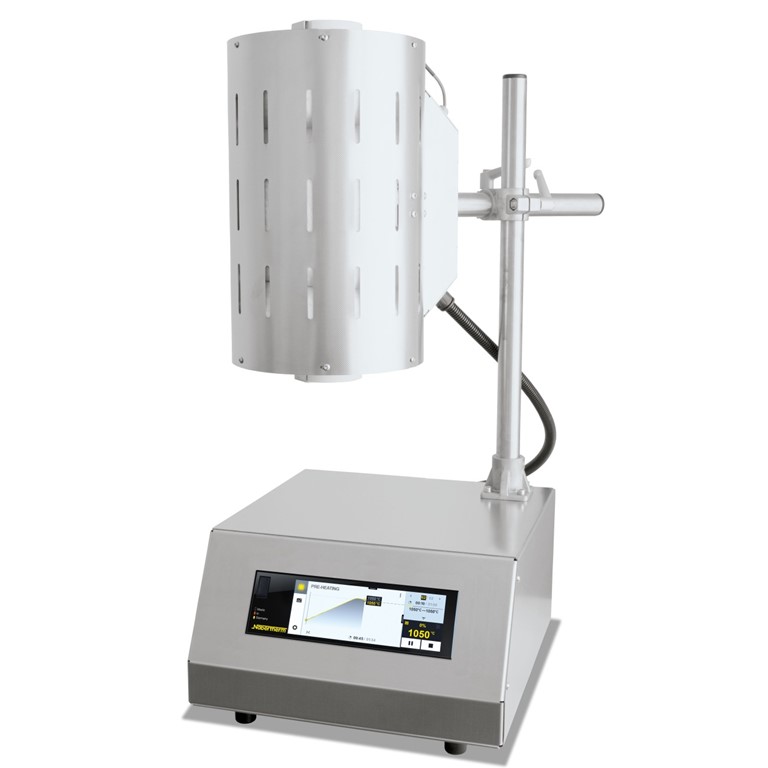

Tube Furnaces with Stand for Horizontal and Vertical Operation up to 1500 °C

These compact tube furnaces are used when laboratory experiments must be performed horizontally, vertically, or at specific angles. The ability to configure the angle of tilt and the working height, and their compact design, also make these tube furnaces suitable for integration into existing process systems.

🟨 Tmax 1100 °C, 1300 °C, or 1500 °C

🟨 Compact design

🟨 Dual shell ventilated housing made of textured stainless steel sheets for low surface temperature and high stability

🟨 Exclusive use of insulation materials without categorization according to EC Regulation No 1272/2008 (CLP). This explicitly means that alumino silicate wool, also known as “refractory ceramic fiber” (RCF), which is classified and possibly carcinogenic, is not used

🟨 Vertical or horizontal operation, infinitely adjustable

🟨 Angle infinitely adjustable from 0 to 90

🟨 Working height infinitely adjustable

🟨 Operation also possible without stand if safety guidelines are observed

🟨 Ceramic working tube C 530 including two fiber plugs for operation under air

🟨 Type S thermocouple

🟨 Solid state relays provide for low-noise operation

🟨 Heating wires wound directly around the working tube resulting in very fast heat-up rates

🟨 Control system integrated in furnace base

🟨 Defined application within the constraints of the operating instructions

🟨 NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

🟨 Controller with touch operation B510 (5 programs with each 4 segments)

High-Temperature Tube Furnaces with SiC Rod Heating up to 1600 °C

These compact tube furnaces with SiC rod heating and integrated switchgear with controller can be used universally for many processes. They represent an inexpensive variant in the high-temperature range. The standard mounting options for accessories make them flexible in use for a wide range of applications. The SiC heating elements arranged parallel to the working tube provide for an excellent temperature uniformity.

🟨 Tmax 1600 °C

🟨 Working temperature 1500 °C, increased wear and tear must be expected when operating at higher temperatures

🟨 Dual shell ventilated housing made of textured stainless steel sheets for low surface temperature and high stability

🟨 Exclusive use of insulation materials without categorization according to EC Regulation No 1272/2008 (CLP). This explicitly means that alumino silicate wool, also known as “refractory ceramic fiber” (RCF), which is classified and possibly carcinogenic, is not used

🟨 Active cooling of housing for low surface temperatures

🟨 Ceramic working tube C 799 including two fiber plugs for operation under air

🟨 Type S thermocouple

🟨 Solid state relays provide for low-noise operation

🟨 SiC heating elements, easy to replace

🟨 Defined application within the constraints of the operating instructions

🟨 NTLog Basic for Nabertherm controller: recording of process data with USB flash drive

🟨 Controller with touch operation P580 (50 programs with each 40 segments)

High-Temperature Tube Furnaces for Horizontal or Vertical Operation up to 1800 °C

The high-temperature tube furnaces are available in either horizontal (type RHTH) or vertical (type RHTV) designs. High-quality insulation materials made of vacuum-formed fiber plates enable energy-saving operation due to low heat storage and low heat conductivity. By using different gas supply systems, operations can be performed under non-flammable or flammable protective or reactive gases, or under vacuum.

🟨 Tmax 1600 °C, 1700 °C, or 1800 °C

🟨 Single-zoned design

🟨 Dual shell ventilated housing made of textured stainless steel sheets for low surface temperature and high stability

🟨 Exclusive use of insulation materials without categorization according to EC Regulation No 1272/2008 (CLP). This explicitly means that alumino silicate wool, also known as “refractory ceramic fiber” (RCF), which is classified and possibly carcinogenic, is not used

🟨 Insulation with vacuum-formed ceramic fiber plates

🟨 Tube furnaces RHTV with frame for vertical operation

🟨 Type B thermocouple

🟨 Solid state relays provide for low-noise operation

🟨 Ceramic working tube C 799 including two fiber plugs for operation under air

🟨 Hanging and easy to change MoSi₂ heating elements

🟨 Power unit with low-voltage transformer and thyristor

🟨 Over-temperature limiter with adjustable cutout temperature as temperature limiter to protect the furnace and load

🟨 Switchgear and control unit separate from furnace in separate floor-standing cabinet

🟨 Defined application within the constraints of the operating instructions

🟨 NTLog Basic for Nabertherm controller: recording of process data with USB flash drive

🟨 Controller with touch operation P570 (50 programs with each 40 segments)

Customized Tube Furnaces

With their high level of flexibility and innovation, Nabertherm offers the optimal solution for customer-specific applications. Based on our standard models, we develop individual solutions also for integration in overriding process systems. The solutions shown on this page are just a few examples of delivered furnaces. From processes working under vacuum or protective gas via innovative control and automation technology for a wide selection of temperatures, sizes, lengths, and other properties of tube furnace systems – we will find the appropriate solution for a suitable process optimization.

ΠΑΡΟΜΟΙΑ ΠΡΟΪΟΝΤΑ

Οι μηχανικοί ομογενοποιητές IKA ULTRA-TURRAX προσφέρουν υψηλής απόδ…

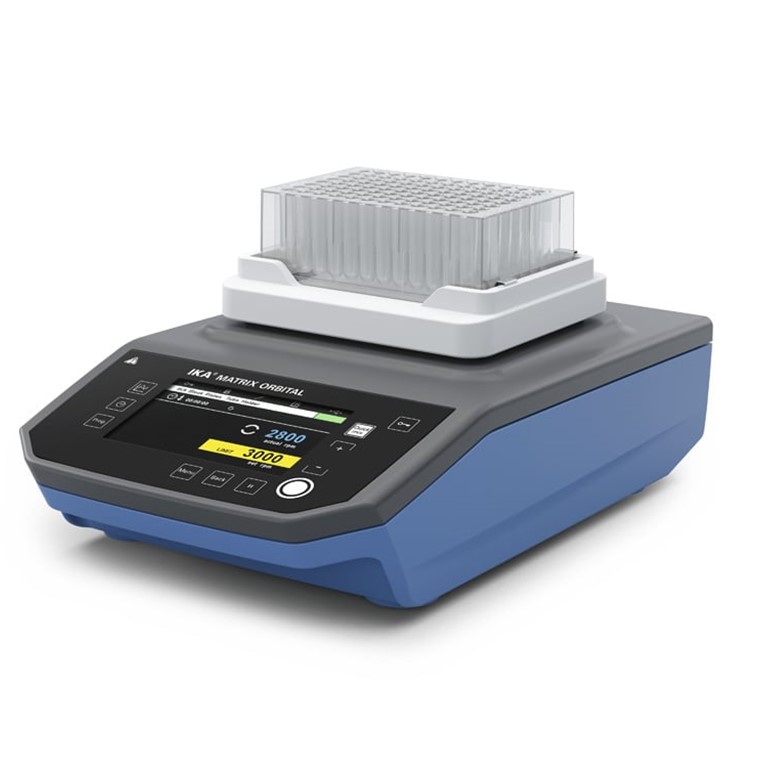

Οι θερμοανακινητήρες της IKA συνδυάζουν ανάδευση, θέρμανση και ψύξη σε μία…

Οι Ανακινητήρες Εργαστηρίου της IKA εξασφαλίζουν ακριβή και σταθερή κί�…

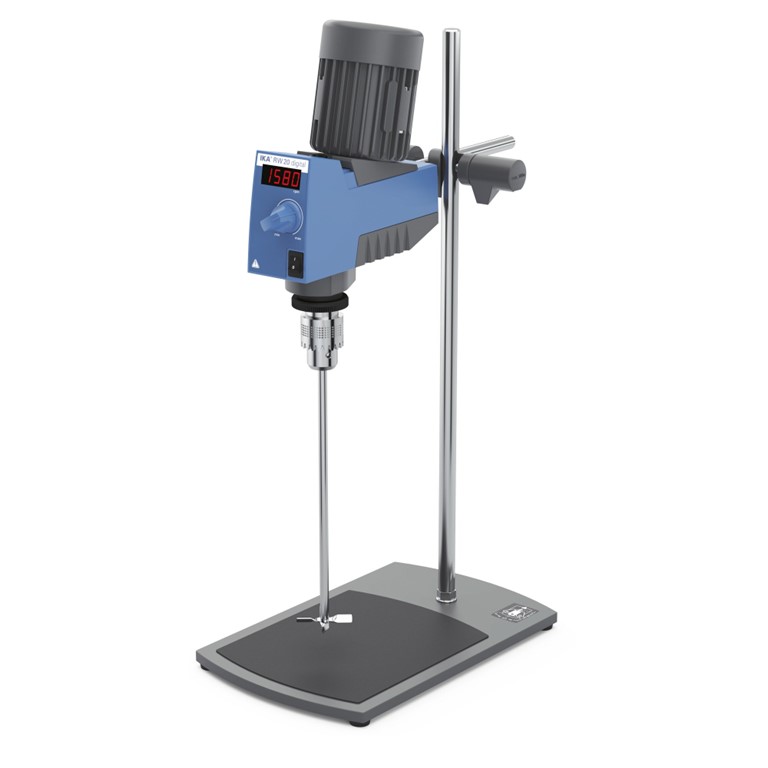

Οι Αναδευτήρες Overhead της IKA προσφέρουν αξιόπιστη και ισχυρή ανάδευση…

Οι μαγνητικοί αναδευτήρες της IKA προσφέρουν υψηλή ενεργειακή απόδοση,…

Οι κλίβανοι ξηρής αποστείρωσης TauSteril προσφέρουν αξιόπιστη και υψη…

Οι κλίβανοι αποστείρωσης της Astell Scientific διατίθενται σε μεγάλο εύ…

Υψηλής απόδοσης λύσεις αποθήκευσης για αίμα, δείγματα και φάρμακα, που κ…

Αυτόματο σύστημα για αναδιάταξη σωληναρίων, ζύγιση, ανίχνευση όγκου και �…

Υψηλής απόδοσης λύσεις σάρωσης για κρυογενικά φιαλίδια και ραφιά, που �…

Πολυκάναλη συσκευή για γρήγορο και εργονομικό άνοιγμα και κλείσιμο καπ…

Τα racks κατάψυξης έχουν σχεδιαστεί για οργανωμένη και αξιόπιστη απο�…