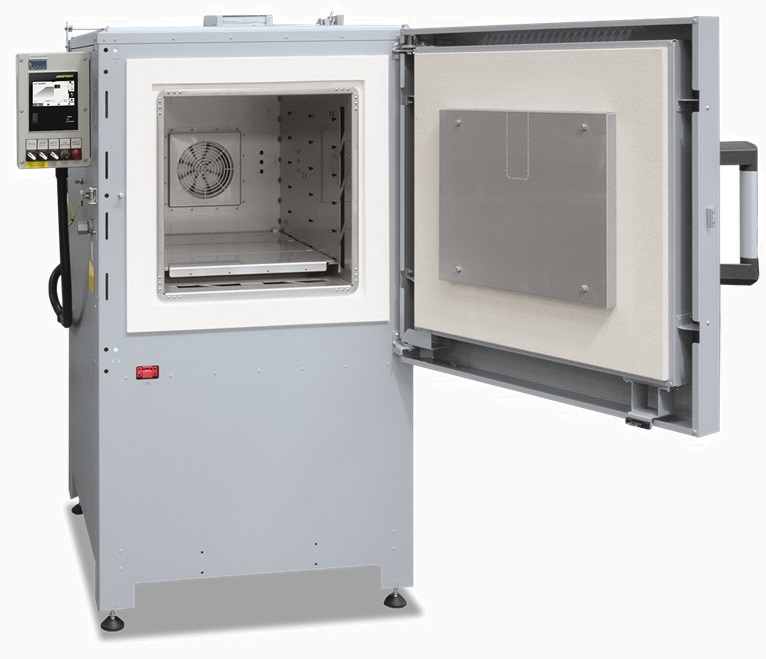

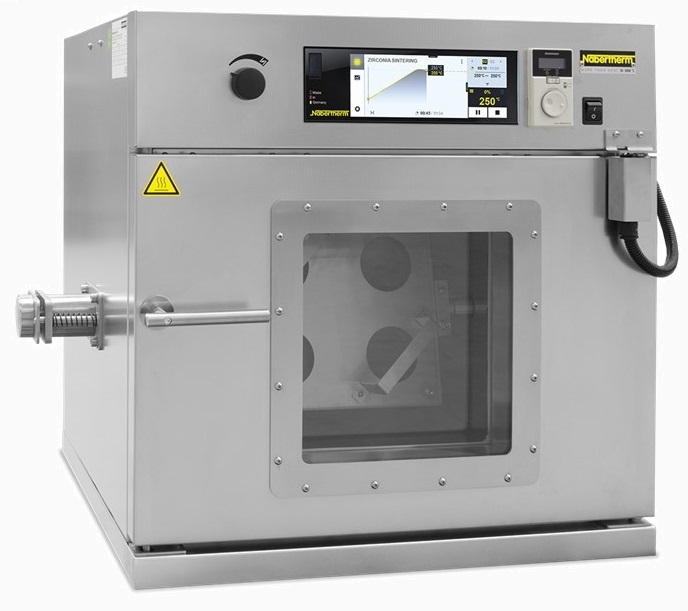

Chamber Furnaces up to 1400 °C are designed for precise heat treatment processes in laboratories and production environments. With their robust box-type design, these furnaces offer uniform temperature distribution, making them ideal for applications such as annealing, hardening, sintering, and material testing. Available in various sizes and configurations, they feature high-quality insulation, intuitive control systems, and durable heating elements for reliable and energy-efficient operation. Optional accessories and customization allow for seamless integration into specific workflows, including use under protective gas atmospheres.

Τετραγωνικοί Kλίβανοι έως 1400 °C

Οι τετραγωνικοί κλίβανοι έως 1400 °C προσφέρουν υψηλή απόδοση σε θερμοκρασίες με ακριβή ομοιομορφία θερμοκρασίας και αξιόπιστα συστήματα ελέγχου. Είναι ιδανικοί για απαιτητικές εργαστηριακές και βιομηχανικές διεργασίες, όπως ανόπτηση, συγκόλληση και θερμική επεξεργασία. Η στιβαρή κατασκευή τους και τα διάφορα διαθέσιμα μεγέθη εξασφαλίζουν ευελιξία σε πολλαπλές εφαρμογές.

Category Πυριαντήρια

Brand: Nabertherm GmbH

Περιγραφή

Chamber Furnaces up to 1400 °C

High-Precision Box Furnaces for Heat Treatment and Material Testing

Chamber Furnaces with Brick Insulation or Fiber Insulation up to 1400 °C

These big chamber furnaces LH 15/12 – LF 120/14 have been trusted for many years as professional chamber furnaces for the laboratory. These furnaces are available with either a robust insulation of light refractory bricks (LH models) or with a combination insulation of refractory bricks in the corners and low heat storage, quickly cooling fiber material (LF models). With a wide variety of optional equipment, these chamber furnaces can be optimally adapted to your processes.

🟨 Tmax: 1200 °C, 1300 °C, or 1400 °C

🟨 Dual shell housing, stainless steel, with fan cooling

🟨 Five-sided heating for uniform temperature

🟨 Support tube elements for efficient heat and long life

🟨 Removable controller for easy operation

🟨 SiC plate protects bottom heating

🟨 LH: refractory brick insulation

🟨 LF: fiber insulation with corner bricks

🟨 Insulation materials free of CLP categorization

🟨 Brick-on-brick door seal, hand fitted

🟨 Strong heating for fast heat-up

🟨 Stable arch protects from dust

🟨 Motorized exhaust flaps

🟨 Adjustable air inlet in floor

🟨 Base included

🟨 Touch controller B500, 5 programs

🟨 Safe use per instructions

🟨 NTLog Basic: USB data recording

Chamber Furnaces for Annealing, Hardening and Brazing up to 1280 °C

These forced convection chamber furnaces are characterized by their excellent temperature uniformity. Due to the compact tabletop design, this series is ideal for laboratories or rooms with limited space.

Applications include preheating of components for shrink-fit processes, heat treatment of metals in air such as aging, stress relieving, soft annealing, or tempering, and heat treatment of glass.

🟨 Tmax 650 °C or 850 °C

🟨 Horizontal air circulation with stainless steel baffles for optimal distribution

🟨 Dual-shell stainless steel housing for low surface temp and high stability

🟨 Integrated control unit

🟨 Right-hinged swing door, usable up to 400 °C

🟨 Temperature uniformity up to ±6 °C (model NAT 15/65: ±5 °C)

🟨 High flow speeds for efficient air distribution

🟨 Air inlet at rear, adjustable exhaust and 15 mm port in ceiling (except NAT 15/65)

🟨 Over-temperature limiter with adjustable cutout

🟨 No RCF insulation – CLP-compliant

🟨 Controller B500/B510 (5 programs × 4 segments)

🟨 NTLog Basic – USB data recording

🟨 Freeware: NTEdit, NTGraph, MyNabertherm App for monitoring and documentation

Forced Convection Chamber Furnaces up to 675 Lt (Electrically Heated)

The very good temperature uniformity of these chamber furnaces with air circulation ensures ideal process conditions for annealing, curing, solution annealing, artificial ageing, sintering of PTFE, preheating, soft annealing, and brazing. These forced convection chamber furnaces are equipped with a suitable annealing box for soft annealing of copper, tempering of titanium, and annealing of steel under non-flammable process gases. The modular design allows for adaptation to specific process requirements through the use of appropriate accessories.

🟨 Tmax 450 °C, 650 °C, or 850 °C

🟨 Horizontal air circulation with stainless steel baffles for optimal distribution

🟨 Swing door hinged on right side

🟨 Base frame included

🟨 Temperature uniformity up to ±4 °C (DIN 17052-1)

🟨 High flow speeds for optimal air distribution

🟨 Includes one frame sheet and rails for two trays

🟨 Over-temperature limiter with adjustable cutout

🟨 No RCF insulation – fully CLP-compliant

🟨 Controller B500 (5 programs × 4 segments)

🟨 Fan auto switch-off for 2 minutes after door opening

🟨 Side port and 3 mm thermocouple entry port

🟨 NTLog Basic – USB data logging

🟨 Freeware: NTEdit, NTGraph, and MyNabertherm App for monitoring

Ovens with Safety Technology

Ovens in the TR .. LS range with safety equipment based on EN 1539 Type A are suitable for drying charges containing solvents. With their compact design, these ovens can be easily integrated into a laboratory or production process. Exhaust gases escape through an outlet on the back of the oven and can then be extracted or treated.

🟨 Furnace technology based on ovens

🟨 For safety technology, see models NA 120/45 LS ff.

🟨 Tmax 260 °C

🟨 Temperature uniformity ±8 K (DIN 17052-1, empty workspace)

🟨 No RCF insulation – fully CLP-compliant

🟨 Defined application within operating instructions

🟨 Controller B510 (5 programs × 4 segments)

🟨 NTLog Basic – USB data recording

🟨 Freeware: NTEdit, NTGraph, and MyNabertherm App for monitoring and documentation

Forced Convection Chamber Furnaces up to 500 Liter Safety Technology

Due to their very good temperature uniformity, these chamber furnaces with air circulation are especially suitable for processes such as drying paints, components with residues of flammable cleaning agents, or the evaporation of solvents bound in the components.

🟨 Design based on forced convection chamber furnaces

🟨 High-powered heating to maintain required air exchange rates

🟨 Powerful exhaust air fan ensures underpressure in furnace

🟨 Monitored air circulation and exhaust air

🟨 Visual and audible malfunction signals

🟨 Over-temperature limiter with manual reset for furnace/load protection

🟨 No RCF insulation – fully CLP-compliant

🟨 Defined application within operating instructions

🟨 Touch controller P570 (50 programs × 40 segments)

🟨 NTLog Basic – USB data recording

🟨 Freeware: NTEdit, NTGraph, and MyNabertherm App

ΠΑΡΟΜΟΙΑ ΠΡΟΪΟΝΤΑ

Οι μηχανικοί ομογενοποιητές IKA ULTRA-TURRAX προσφέρουν υψηλής απόδ…

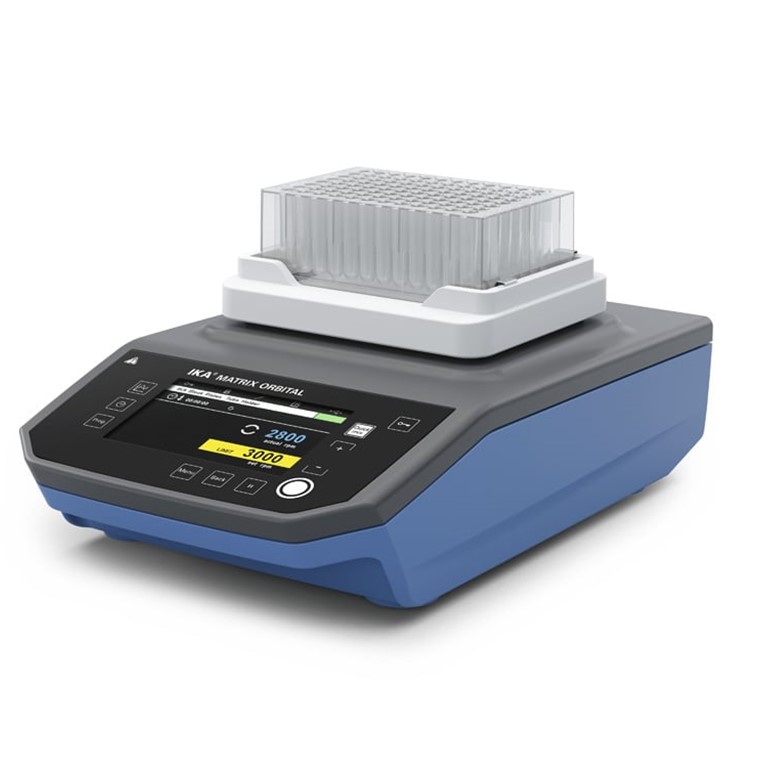

Οι θερμοανακινητήρες της IKA συνδυάζουν ανάδευση, θέρμανση και ψύξη σε μία…

Οι Ανακινητήρες Εργαστηρίου της IKA εξασφαλίζουν ακριβή και σταθερή κί�…

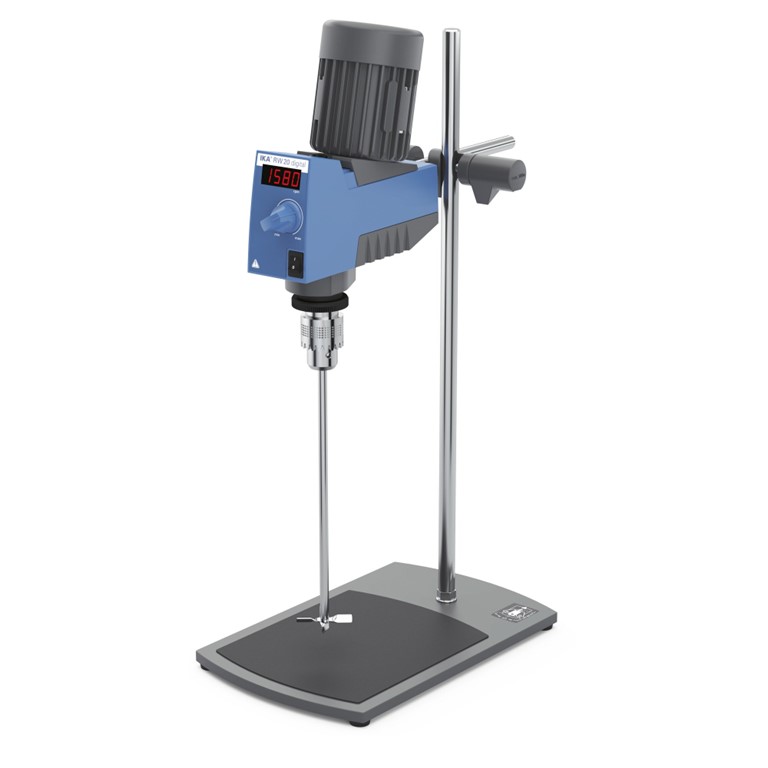

Οι Αναδευτήρες Overhead της IKA προσφέρουν αξιόπιστη και ισχυρή ανάδευση…

Οι μαγνητικοί αναδευτήρες της IKA προσφέρουν υψηλή ενεργειακή απόδοση,…

Οι κλίβανοι ξηρής αποστείρωσης TauSteril προσφέρουν αξιόπιστη και υψη…

Οι κλίβανοι αποστείρωσης της Astell Scientific διατίθενται σε μεγάλο εύ…

Υψηλής απόδοσης λύσεις αποθήκευσης για αίμα, δείγματα και φάρμακα, που κ…

Αυτόματο σύστημα για αναδιάταξη σωληναρίων, ζύγιση, ανίχνευση όγκου και �…

Υψηλής απόδοσης λύσεις σάρωσης για κρυογενικά φιαλίδια και ραφιά, που �…

Πολυκάναλη συσκευή για γρήγορο και εργονομικό άνοιγμα και κλείσιμο καπ…

Τα racks κατάψυξης έχουν σχεδιαστεί για οργανωμένη και αξιόπιστη απο�…