Linseis – Διαστολόμετρα (Dilatometer)

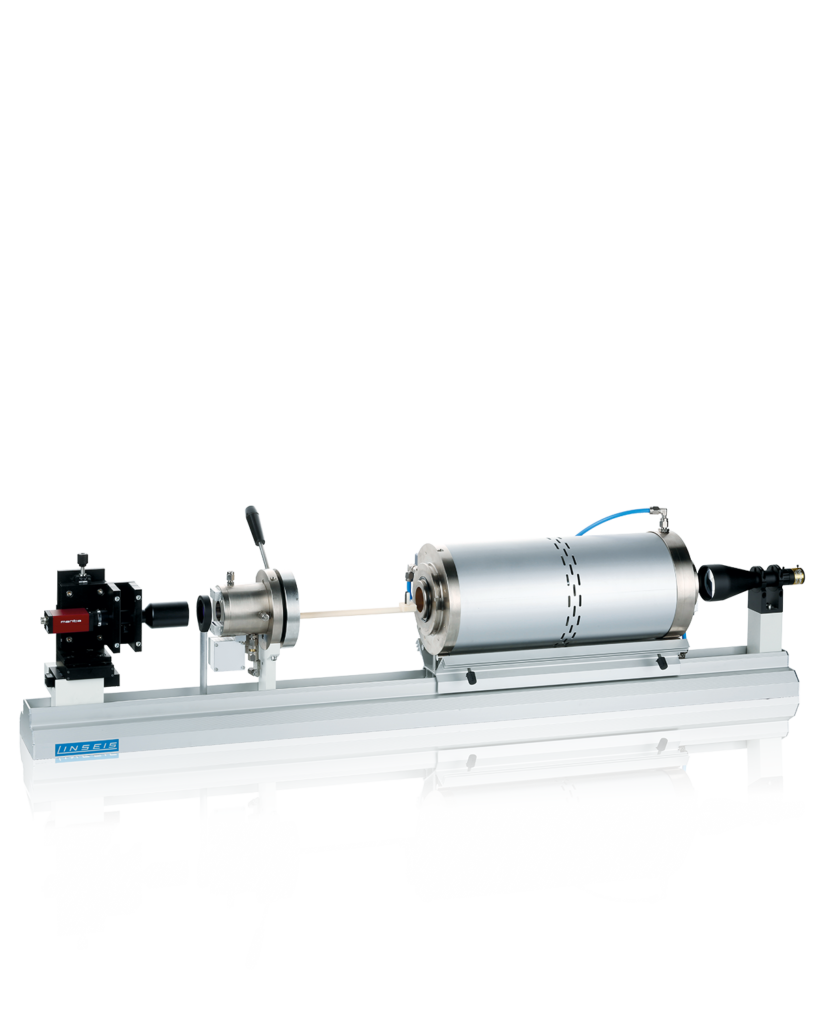

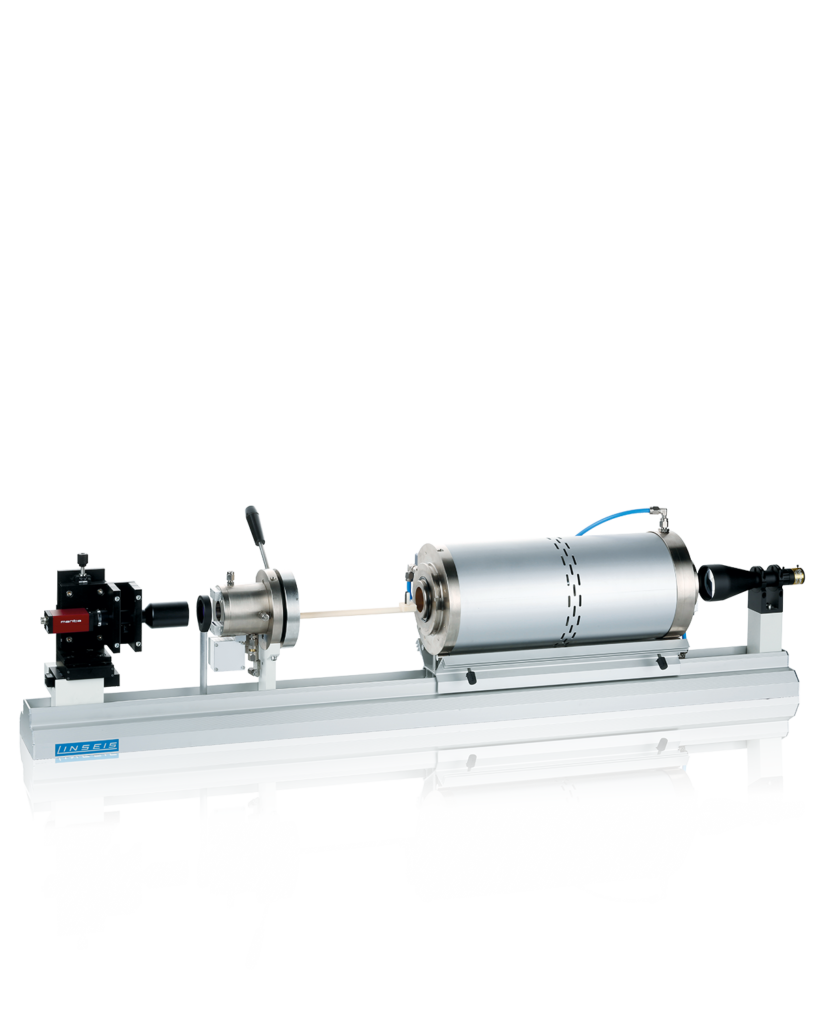

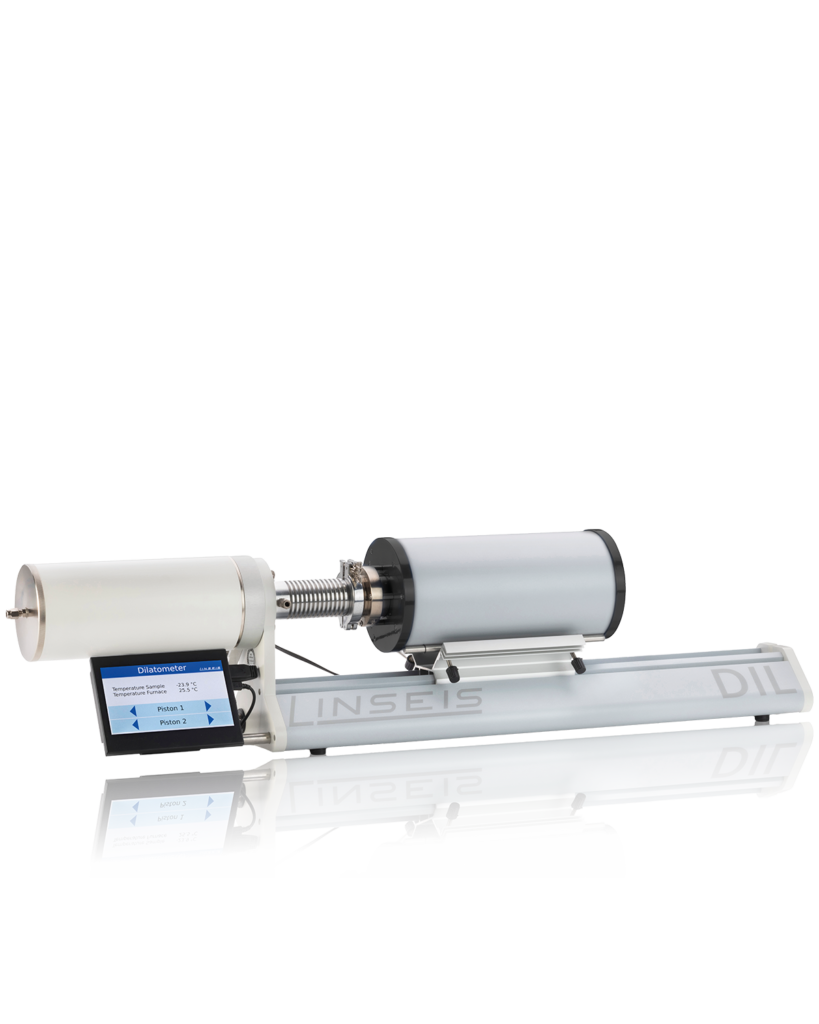

Η Linseis προσφέρει μια σειρά από υψηλής ακρίβειας διαστολόμετρα για μετρήσεις θερμικής διαστολής στις επιστήμες των υλικών. Τα προϊόντα περιλαμβάνουν μονοπύρηνα, διπλά και διαφορικά διαστολόμετρα, καθώς και οπτικά και οριζόντια μοντέλα, καλύπτοντας τις ανάγκες στην έρευνα, τον έλεγχο ποιότητας, καθώς και σε βιομηχανικές εφαρμογές. Παρέχουν αξιόπιστη ανάλυση για στερεά, υγρά και σκόνες, σε θερμοκρασίες από κρυογενείς συνθήκες, έως άνω των 2800°C. Με δυνατότητες προσαρμογής και εξελιγμένο λογισμικό, είναι κατάλληλα για απαιτητικές ερευνητικές εργασίες.

Categories Αναλυτικός Εξοπλισμός, Διαστολομετρία (Dilatometry)

Brand: Linseis

Περιγραφή

Dilatometry - Expansion measurement - DIL

Measuring Principle

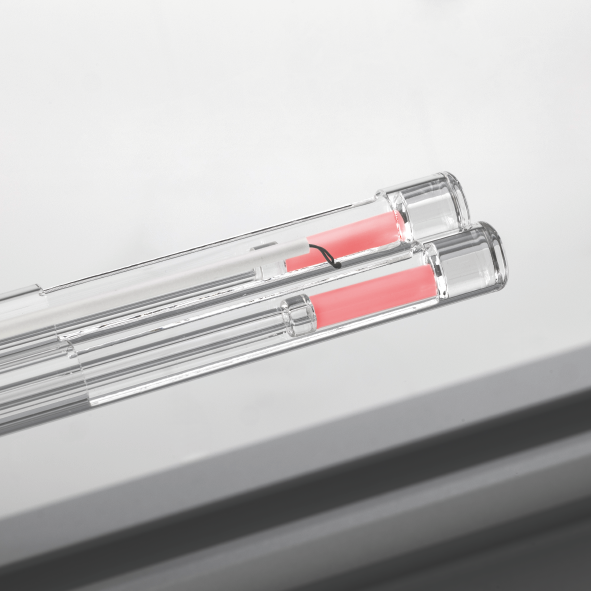

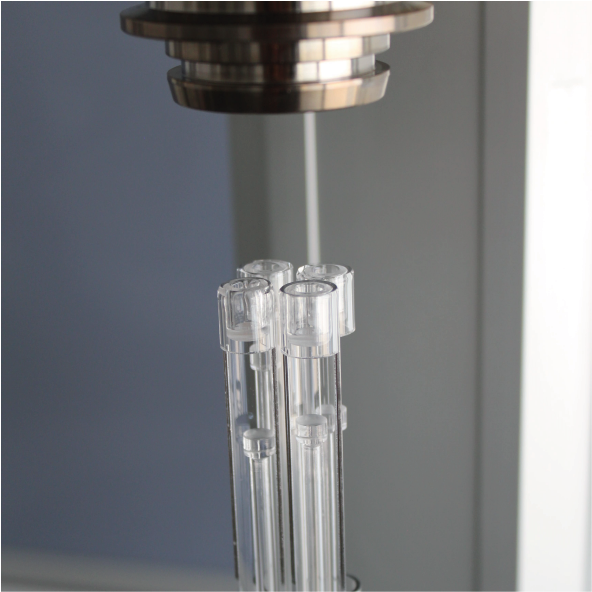

Linseis dilatometers offer maximum precision and enable automatic length change measurement of solids, powder pastes and liquids.

All Linseis dilatometers comply with international standards such as ASTM E831, ASTM D696, ISO 11358, ISO/DIS 9924, ASTM E1131, ASTM D3850, ASTM D6375, ASTM D6370, ASTM E2550 and ASTM D3175.

➡️ Measured variables and applications:

- Determination of the coefficient of thermal expansion (CTE)

- Linear thermal expansion (ΔL)

- Sintering temperatures and sintering stages

- Determination of the glass transition (Tg)

- Phase transitions

- Optimization of firing processes

- Volume changes

- Rate-controlled sintering (RCS)

- Decomposition

- Density change

Linseis Dilatometer Series

Horizontal vs. vertical structure

Horizontal alignment

- Simple and robust design at a moderate price

- Perfect choice for the medium temperature range

- Simple sample handling

- Customized dilatometers available for large samples

Vertical alignment

- Zero friction design (the sample is only in contact with the end stop and the push rod)

- Arrangement of several ovens (up to three ovens)

- to cover the entire temperature range from -180 to 2800°C, particularly ideal for low and very high temperatures

- to increase throughput (hot oven can be started up automatically to switch to a new cold oven and start a new measurement)

- perfect for measurements at low temperatures (oven below – measuring compartment above) to ensure access to the gas, cold air (falling downwards) below the sensor area

- perfect for high temperature measurements (oven above – measuring chamber below) to ensure access to the gas, hot air (flows upwards) above the sensor chamber

- low space requirement and low demands on the laboratory space

- available as single, differential/double and quattro arrangement (1, 2 or 4 samples simultaneously)

ΙΔΑΝΙΚΟ ΓΙΑ

Linseis dilatometers are ideal for:

- Thermal Expansion Analysis: Measuring thermal behavior in materials.

- Materials Science Applications: Studying ceramics, polymers, metals, and composites.

- Research & Development: Supporting high-precision experimental studies.

- Quality Control: Ensuring material consistency and performance.

- Industrial Use: Suitable for production and process optimization.

- Broad Temperature Ranges: Operating from cryogenic levels to over 2800°C.

- Diverse Material Forms: Analyzing solids, liquids, and powders.

ΠΑΡΟΜΟΙΑ ΠΡΟΪΟΝΤΑ

Οι μηχανικοί ομογενοποιητές IKA ULTRA-TURRAX προσφέρουν υψηλής απόδ…

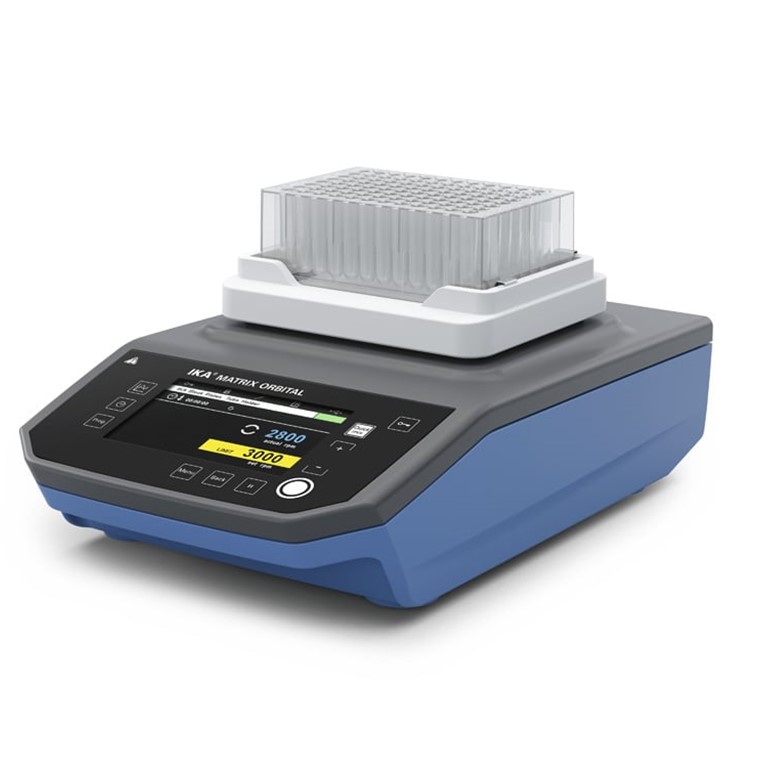

Οι θερμοανακινητήρες της IKA συνδυάζουν ανάδευση, θέρμανση και ψύξη σε μία…

Οι Ανακινητήρες Εργαστηρίου της IKA εξασφαλίζουν ακριβή και σταθερή κί�…

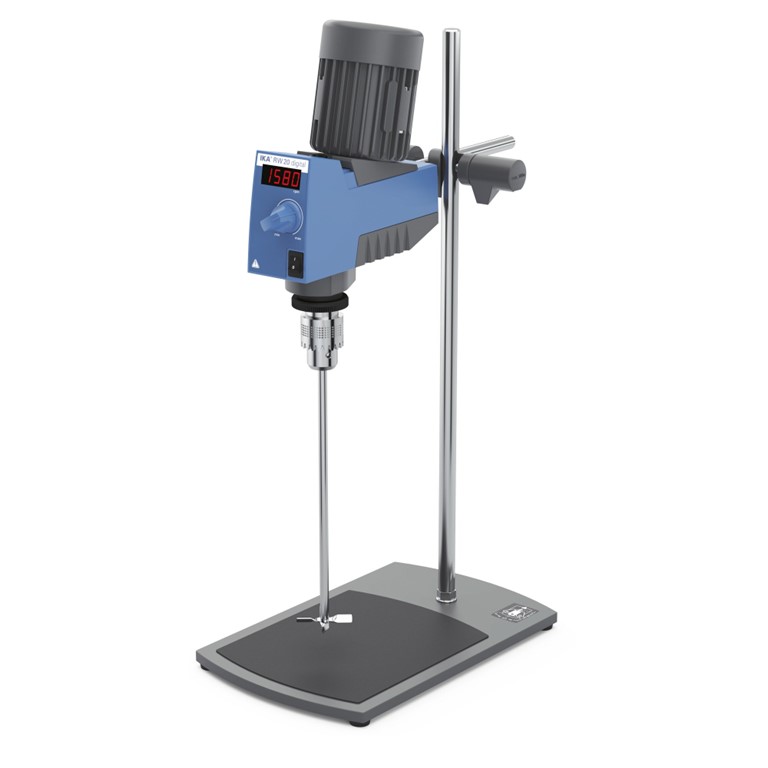

Οι Αναδευτήρες Overhead της IKA προσφέρουν αξιόπιστη και ισχυρή ανάδευση…

Οι μαγνητικοί αναδευτήρες της IKA προσφέρουν υψηλή ενεργειακή απόδοση,…

Οι κλίβανοι ξηρής αποστείρωσης TauSteril προσφέρουν αξιόπιστη και υψη…

Οι κλίβανοι αποστείρωσης της Astell Scientific διατίθενται σε μεγάλο εύ…

Υψηλής απόδοσης λύσεις αποθήκευσης για αίμα, δείγματα και φάρμακα, που κ…

Αυτόματο σύστημα για αναδιάταξη σωληναρίων, ζύγιση, ανίχνευση όγκου και �…

Υψηλής απόδοσης λύσεις σάρωσης για κρυογενικά φιαλίδια και ραφιά, που �…

Πολυκάναλη συσκευή για γρήγορο και εργονομικό άνοιγμα και κλείσιμο καπ…

Τα racks κατάψυξης έχουν σχεδιαστεί για οργανωμένη και αξιόπιστη απο�…