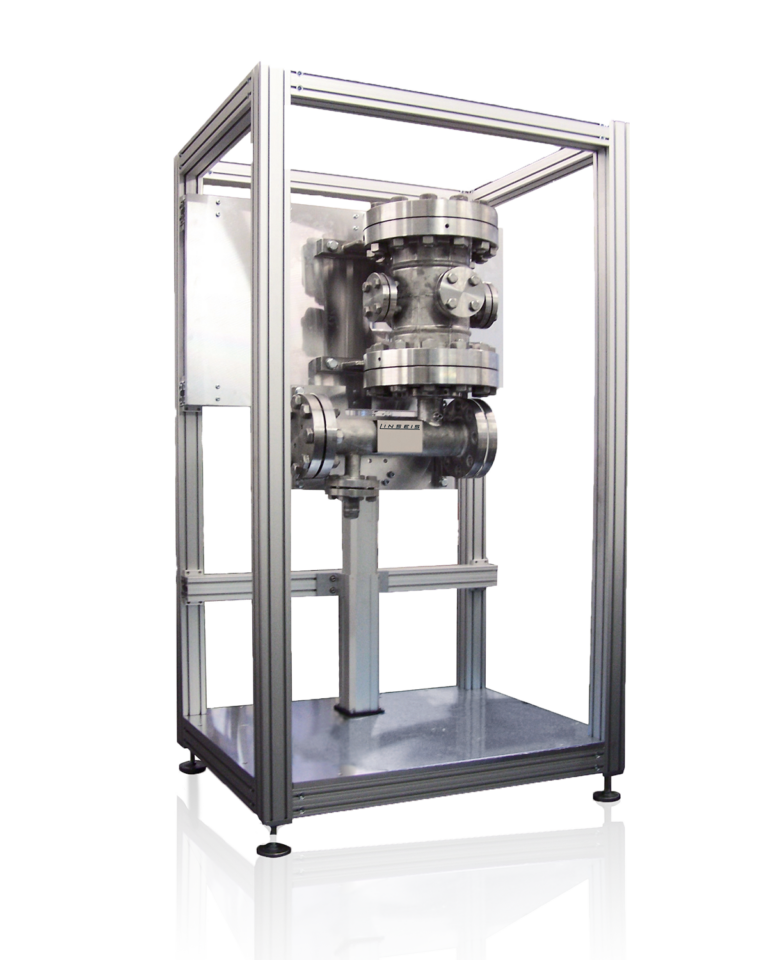

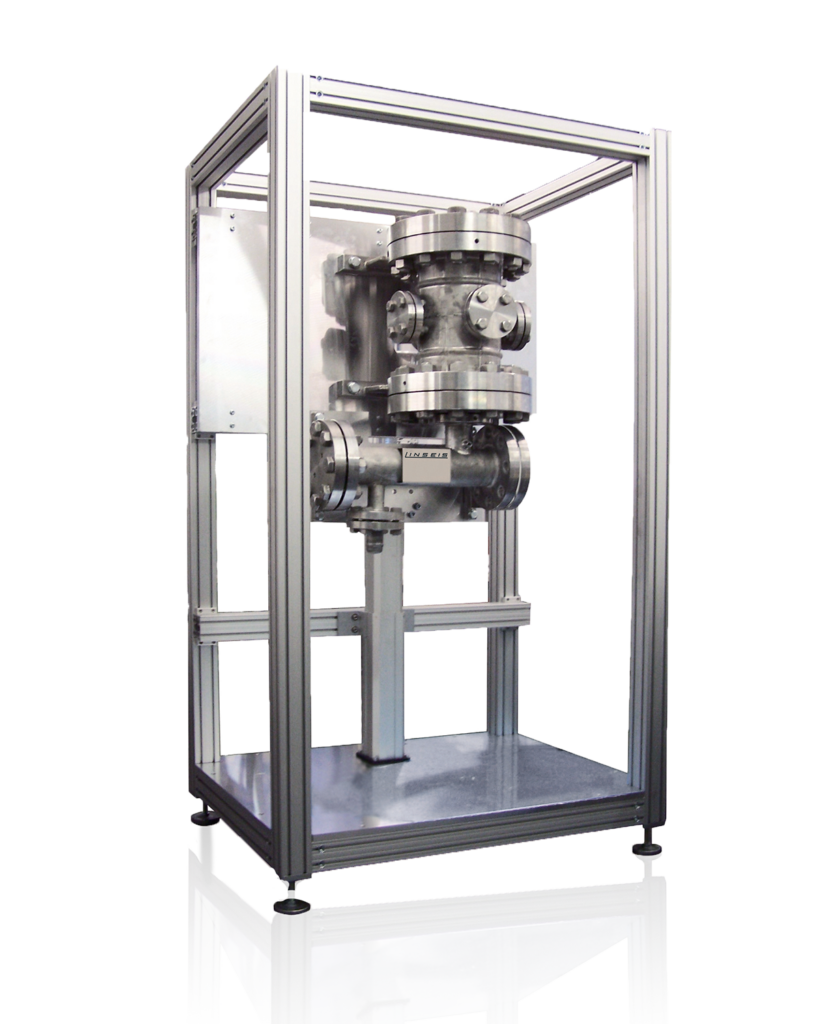

Linseis – High-pressure measuring devices

Linseis high-pressure measuring devices enable thermal analysis under extreme pressure conditions, crucial for studying material behavior in environments like oil, gas, or chemical industries. These instruments support various techniques, including Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA), ensuring precise results in challenging scenarios. Designed for durability and versatility, they cater to research and industrial applications needing robust high-pressure data.

High-pressure thermal analysis

LINSEIS high-pressure thermal analyzers work according to the same measuring methods as their ambient pressure models, but can be operated at high temperatures up to 150 bar pressure.

This enables the investigation of pressure-dependent phenomena such as sorption or chemical reactions.

Both are of great interest for the development of new materials and processes for renewable (green) energies.

In hydrogen technology, hydrogen storage is crucial, and storage materials (metal hydrides) and storage conditions (pressure, temperature) need to be investigated.

Another example is biomass gasification.

The process parameters for the conversion of biomass into so-called syngas, which can be used as a fuel or as a precursor for methanol or other useful chemicals, can be investigated by varying the pressure, temperature and chemical composition of the gas atmosphere.

All this can be simulated in LINSEIS high-pressure analyzers.

Linseis: high-pressure series

Downloads

IDEAL FOR

Linseis high-pressure measuring devices are primarily designed for applications that require precise measurements of various properties under high-pressure conditions. These devices are ideal for use in a variety of industries and scientific fields. Some of their key applications include:

- Materials Science and Research:

- Phase Transitions: Linseis high-pressure devices are often used to study the behavior of materials under extreme pressure conditions, including phase transitions (e.g., solid-liquid, solid-gas).

- High-Pressure Thermodynamics: They are ideal for determining thermodynamic properties such as specific heat, thermal conductivity, and expansion under high pressure, which can vary significantly from standard conditions.

- Petroleum and Natural Gas Industry:

- Reservoir Studies: These devices are used to simulate and analyze conditions found in deep geological formations, which is crucial for understanding reservoir behavior and improving extraction methods.

- Gas Mixture Properties: High-pressure measuring devices help analyze the physical properties of natural gas and other mixtures under pressurized conditions, which is essential for designing pipelines, storage systems, and other infrastructure.

- Chemical Engineering:

- Reaction Kinetics and Catalysis: In chemical processes, particularly those involving gas reactions, high-pressure devices help monitor reaction rates and determine the effectiveness of catalysts under pressure.

- Solubility Studies: They are used for studying the solubility of gases in liquids at high pressures, which is crucial for processes like carbonation or supercritical fluid extraction.

- Geophysics and Earth Sciences:

- High-Pressure Experimentation: For simulating conditions found deep within the Earth (e.g., mantle studies), these devices help replicate high-pressure environments to investigate rock behavior, mineral stability, and other geophysical properties.

- Seismology and Earthquake Simulation: They are also used to study the properties of materials under pressure for earthquake research and related simulations.

- Cryogenics:

- Low-Temperature and High-Pressure Conditions: Linseis high-pressure measuring devices are valuable in cryogenic applications where both low temperatures and high pressures are involved, such as in the development of refrigeration technologies or in the study of superconductors.

- Automotive and Aerospace:

- Material Testing for Components: These devices are used to test materials and components under extreme pressures to assess their durability, performance, and failure points in automotive and aerospace engineering.

- Hydraulic Systems: High-pressure measuring devices are essential for the testing and optimization of hydraulic systems, which often operate under high-pressure conditions.

- Pharmaceuticals:

- Drug Development: The devices can be used for the study of solubility, stability, and chemical reactions of drugs under high pressures, which may influence the formulation of pharmaceutical products.

Overall, Linseis high-pressure measuring devices are ideal for applications that require precise, accurate, and reliable measurements under extreme pressures, aiding in the development of materials, chemicals, and processes across various industries.

FEATURES

MODEL |

STA HP |

|---|---|

| Temperature range: | 170°C up to 1200°C / 1600°C / 1800°C |

| Vacuum: | Up to 10-4 mbar |

| Max pressure: | max. 150 bar (customised solutions on request) |

| Temperature precision: | 0.05°C |

TG |

||

|---|---|---|

| Resolution: | 0.1 μg | 0.1 μg |

| Sample weight: | The scales can recognise the weight automatically | The scales can recognise the weight automatically |

| Measuring range: | 25 / 2500 mg | 35000 mg |

DSC |

||

|---|---|---|

| DSC resolution: | 0,3 / 0,4 / 1 µW | 0,3 / 0,4 / 1 µW |

| DSC sensors: | E /K / S / B / C | E /K / S / B / C |

| Calorimetry sensitivity: | ca. 4 / 6 / 17.6 / 22.5 μW | ca. 4 / 6 / 17.6 / 22.5 μW |

DTA |

||

|---|---|---|

| DTA resolution: | 0.03 nV | 0.03 nV |

| Sensitivity: | 1.5 μV / mW | 1.5 μV / mW |

| DTA measuring ranges: | 250 / 2500 μV | 250 / 2500 μV |

MODEL |

TGA HP 3 |

|---|---|

| Temperature range: | RT up to 1200°C |

| Pressure range: | up to 150 bar |

| Sample size: | up to 5 g |

| Resolution: | 0.1 ug |

| Vacuum: | 10E-4 mbar |

| TG sensors: | Type E/K/S/B/C |

| TG-DSC sensors: | Type E/K/S/B/C |

| Electronics: | Integrated or separately possible |

| Interfaces: | USB or Ethernet |

| Water vapour generator: | Optional |

| Gas dosing: | 1, 2 or 3 gases (others on request) |

MODEL |

STA HP 1/2 |

|---|---|

| Temperature range: | 170°C up to 1200°C / 1600°C / 1800°C |

| Vacuum: | Up to 10-4 mbar |

| Max pressure: | max. 150 bar (customised solutions on request) |

| Temperature precision: | 0.05°C |

TG |

||

|---|---|---|

| Resolution: | 0.1 μg | 0.1 μg |

| Sample weight: | The scales can recognise the weight automatically | The scales can recognise the weight automatically |

| Measuring range: | 25 / 2500 mg | 35000 mg |

DSC |

||

|---|---|---|

| DSC resolution: | 0,3 / 0,4 / 1 µW | 0,3 / 0,4 / 1 µW |

| DSC sensors: | E /K / S / B / C | E /K / S / B / C |

| Calorimetry sensitivity: | ca. 4 / 6 / 17.6 / 22.5 μW | ca. 4 / 6 / 17.6 / 22.5 μW |

DTA |

||

|---|---|---|

| DTA resolution: | 0.03 nV | 0.03 nV |

| Sensitivity: | 1.5 μV / mW | 1.5 μV / mW |

| DTA measuring ranges: | 250 / 2500 μV | 250 / 2500 μV |

MODEL |

DIL L75 HP/1* |

|---|---|

| Temperature range: | RT up to 1100°C |

| Max. pressure: | max. 150 bar |

| Vacuum: | 10E-4 mbar |

| Sample holder: | fused silicia < 1100°C, Al2O3 < 1750°C |

| Max. sample length: | 50 mm |

| Sample diameter: | 7/12/20 mm |

| Adjustable sample pressure: | up to 1000 mN |

| Measuring range: | 500 / 5000 µm |

| Resolution: | 0,125 nm |

| Options: | Pressure controllable Gas Mixing System (MFC´s) |

| Atmosphere: | inert, oxid.*, red., vac. |

| *Specifications depend on the configurations |

MODEL |

DIL L75 HP/2* |

|---|---|

| Temperature range: | RT bis 1400/1800°C |

| Max. pressure: | max. 100 bar |

| Vacuum: | 10E-4 mbar |

| Sample holder: | fused silicia < 1100°C, Al2O3 < 1750°C |

| Max. sample length: | 50 mm |

| Sample diameter: | 7/12/20 mm |

| Adjustable sample pressure: | up to 1000 mN |

| Measuring range: | 500 / 5000 µm |

| Resolution: | 0,125 nm |

| Options: | Pressure controllable Gas Mixing System (MFC´s) |

| Atmosphere: | inert, oxid.*, red., vac. |

| *Specifications depend on the configurations |