Flow Reactors

Pressure Reactors for high-pressure, high-temperature reactions in process development and scale-up. Offered in multiple MOCs, with varied sizes from lab to production, and standard accessories. Used in petrochemicals, refining, pharma, and specialty chemicals.

Flow Reactors

Flow reactors are designed to handle a range of aggressive conditions including high temperatures, high pressures, corrosive chemicals, and solid slurries. Models are available from microreactor volumes to lab-scale and pilot-scale systems. All provide exceptionally high mass and heat transfer coefficients due to their large surface area-to-volume ratio. Full support is offered from concept development through scale-up to production scale. An in-house wet lab and analytical services enable live demonstrations for customer projects. Ideal for batch-to-continuous conversion, especially in highly exothermic reactions.

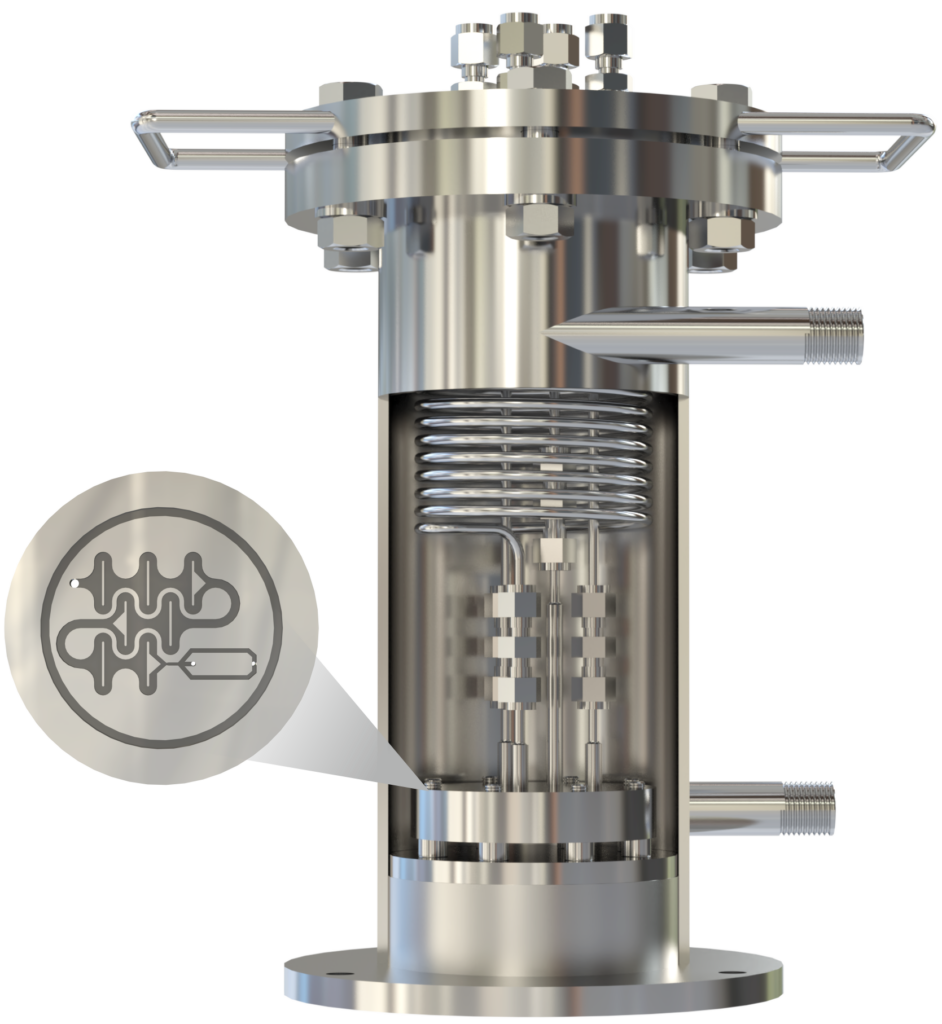

Microreactors – LabFLO™ Reactors

The LabFLO™ is a compact lab-scale flow reactor ideal for proof-of-concept studies. It features a 1 mL micro-mixer and 10 mL residence time coils, immersed in a circulating fluid bath for precise temperature control. Suitable for nitration, sulfonation, diazotization, oxidation, reduction, and similar reactions, it operates efficiently with raw materials in microliter quantities.

➡️ Ideal for liquid-liquid or gas-liquid exothermic reactions & proof-of-concept studies

➡️ High surface area-to-volume ratio compared to traditional reactors

➡️ Volume: 1 mL micromixer & 10 mL residence coil

➡️ Flow Rates: Up to 6 LPH

➡️ Pressure: Up to 50 bar

➡️ Temperature: -50 °C to 350 °C

➡️ Heat Transfer Area: >2,000 m²/m³

➡️ Material: SS-316, Hastelloy, etc.

➡️ Applications: Suitable for Nitration, Halogenation, Sulfonation, Diazotization, Oxidation, Reduction, Lithiations, Grignard-based chemistries.

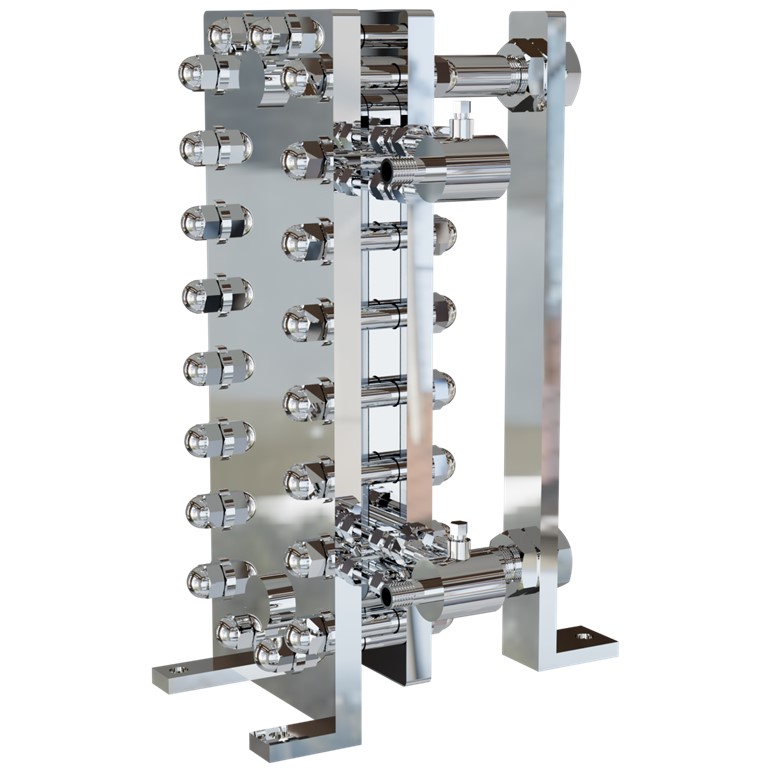

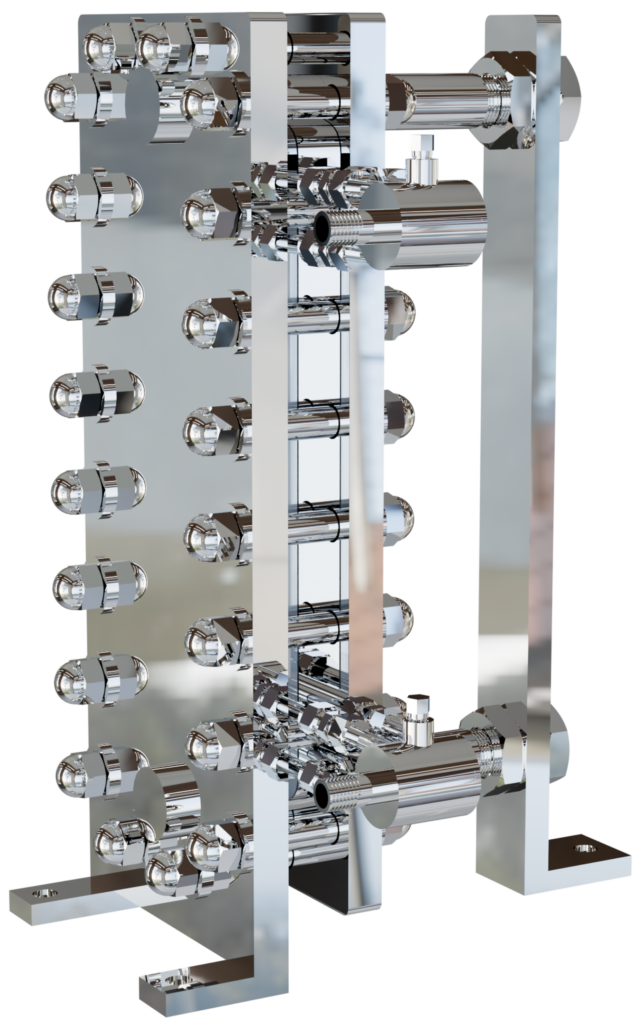

Microreactors – MicroFLO™ Reactors

The MicroFLO™ reactor is a plate-type flow reactor utilizing a split-and-recombine mixing strategy for highly effective mixing and heat dissipation. Its high heat transfer area per unit volume ensures near-isothermal conditions, making it ideal for fast, highly exothermic reactions such as lithiations, Grignard synthesis, and nitrations. With a unique space-filling configuration, it maximizes process volume within a compact footprint. The MicroFLO™ reactor offers excellent pressure resistance—up to 100 bar—significantly outperforming typical glass or ceramic micro-reactors.

➡️ Ideal for gas-liquid and liquid-liquid multiphase reactions

➡️ MicroFLO™ is a compact plate-type flow reactor with significantly higher surface area-to-volume and heat transfer area than standard reactors

➡️ Achieved through a space-filling patented design

➡️ Available in 3D printed and plate-type configurations

➡️ Volume: 5 mL to 2 L

➡️ Flow Rates: Up to 100 LPH

➡️ Pressure: Up to 100 bar

➡️ Temperature: -50 °C to 350 °C

➡️ Heat Transfer Area: 500–2,500 m²/m³

➡️ Material: SS-316 & Hastelloy

PhotoFLO™ Reactor

The PhotoFLO™ Reactor is a compact photochemical flow reactor based on the space-filling MicroFLO™ platform. It ensures efficient photon utilization, along with excellent heat and mass transfer. Designed for continuous photochemical processes, it uses UV-transparent, chemically resistant tubing and operates under controlled temperature and pressure conditions, making it ideal for lab-scale photochemical transformations.

➡️ PhotoFLO™ reactor is based on the compact, space-filling MicroFLO™ design, maximizing photon efficiency

➡️ Volume: 12 mL to 200 mL

➡️ Flow Rates: Up to 10 LPH

➡️ Pressure: Up to 10 bar

➡️ Temperature Range: -20 °C to 200 °C

➡️ Material: SS-316, Hastelloy C, with glass front covering

➡️ Light Source: Variable wavelength LED

➡️ Applications: Photo-halogenations, Photo-alkylation, Photo-oxidation, Photolysis, Photo-Fries rearrangements

Tubular Reactors – PinchFLO™ Reactor

The PinchFLO™ Reactor is a passive mixing flow reactor that utilizes the kinetic energy of the fluid for mixing and heat transfer, without external agitation. It features a series of pinched tubes with contoured surfaces that enhance internal flow dynamics. Ideal for nitrations, diazotizations, ozonolysis, and slower Grignard syntheses, it offers a simple yet effective solution for continuous reaction control and process efficiency.

➡️ PinchFLO™ tubular reactor ideal for liquid-liquid and gas-liquid exothermic reactions at commercial scale

➡️ Volume: 50 mL to 1,000 L

➡️ Flow Rates: Up to 10,000 LPH

➡️ Pressure: Up to 100 bar

➡️ Temperature: –50 °C to 350 °C

➡️ Material: SS-316 / Hastelloy

➡️ Designs: Double pipe, shell & tube jackets

➡️ Patented design from NCL, Pune

Tubular Reactors – CorFLO™ Reactor

The CorFLO™ Reactor is a passive mixing device that harnesses the kinetic energy of the flowing fluid for efficient mixing and enhanced heat transfer. It features corrugated tubes with kinetics-type static mixers, delivering superior performance even at low flow rates and with narrow residence time distributions. Ideal for nitrations, ozonolysis, polymerizations, and nucleophilic substitutions, it is particularly suited for processes demanding precise residence time control.

➡️ CorFLO™ reactor suited for mixing-intensive processes at commercial scale

➡️ Specially designed tubes offer higher heat & mass transfer with lower pressure drop than plain tubes

➡️ Volume: 50 mL to 1,000 L

➡️ Flow Rates: Up to 10,000 LPH

➡️ Pressure: Up to 100 bar

➡️ Temperature: –30 °C to 350 °C

➡️ Material: SS316, Hastelloy C

➡️ Applications: Polymerization, blending of reagents, neutralization reactions, emulsification, bioprocessing, adhesives, sealants, coatings

Tubular Reactors – TubularFLO™ Reactor

The TubularFLO™ Reactors are custom-designed for precise control of residence time, temperature, and pressure in scale-up and production. They handle a variety of reactive chemistries and offer excellent scalability from lab to commercial scale.

➡️ Plain tube or plain tube with static mixer for improved mixing

➡️ Volume: 50 mL to 1,000 L

➡️ Flow Rates: Up to 10,000 LPH

➡️ Pressure: Up to 100 bar

➡️ Temperature: -50°C to 350°C

➡️ Material: SS-316 / Hastelloy

➡️ Design: Double pipe, shell & tube jacket

➡️ Applications: Single-phase reactions including aldol condensations, esterifications, nitrations, polymerization, blending, neutralization, emulsification, and bioprocessing for adhesives, sealants, and coatings manufacturing

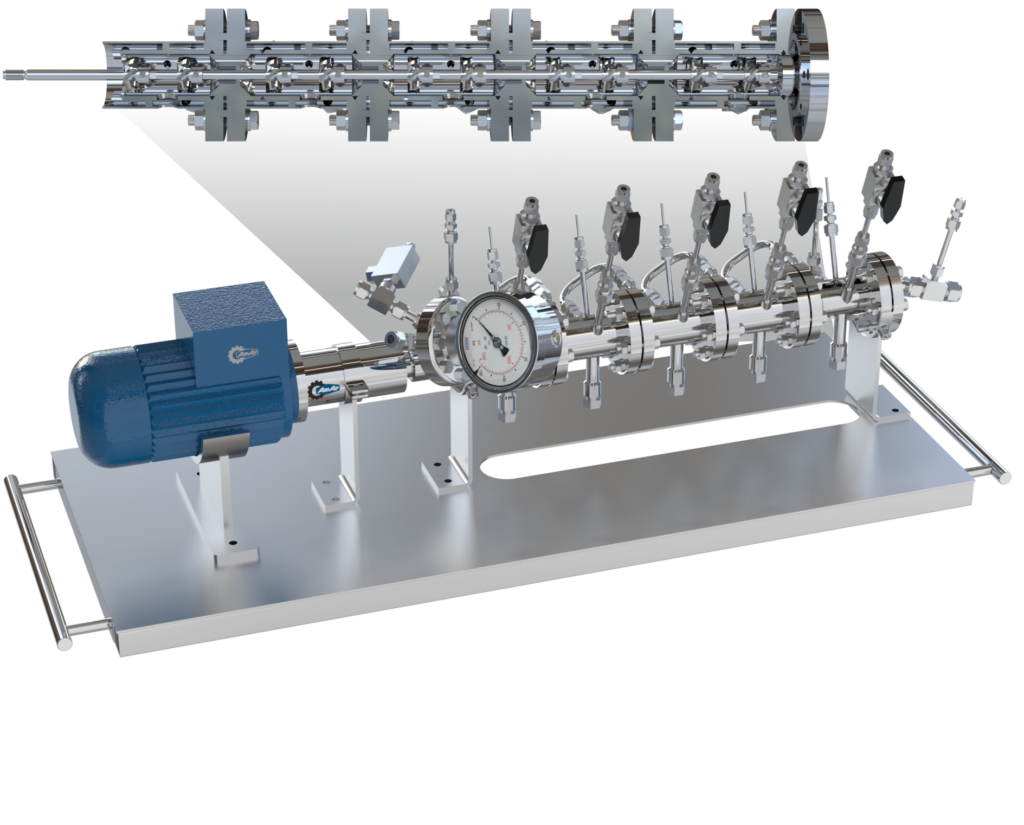

Slurry Handling Reactors – SlurryFLO™ Reactor

The SlurryFLO™ Reactor is a versatile continuous flow reactor designed for challenging slurry reactions and process intensification. Its partitioned cell design with impellers on a single shaft enables active agitation for thorough dispersion. This maximizes heat transfer to the jacketed walls, ensuring precise isothermal conditions vital for multi-phase flow processes.

➡️ Volume: 250 mL to 100 L, custom reactors up to 1,000 L

➡️ Flow Rates: Up to 300 LPH

➡️ Pressure: Up to 100 bar

➡️ Temperature: -30 °C to 250 °C

➡️ Material: SS316, Hastelloy C, Glass with Metal

➡️ Applications: Heterogeneously catalyzed reactions with finely dispersed catalysts, including hydrogenations, nucleophilic substitutions, aldol condensations, esterifications, and continuous crystallization with uniform crystal-size distribution

Slurry Handling Reactors – MACFLO™ Reactor

The MACFLO™ Reactor is a patented multiphasic agitated contactor reactor engineered for a variety of challenging flow applications. It is designed to handle reactions involving slurries, viscous fluids, gas-liquid-solid contacting, fast exothermic reactions, long residence time reactions, and continuous crystallizations. The reactor offers precise control over residence time, temperature, and pressure, making it suitable for processes requiring efficient mixing and heat transfer.

➡️ Patented multiphasic agitated contactor reactor for challenging flow applications

➡️ Volume: 250 mL to 100 L; custom reactors 100 L to 1,000 L

➡️ Flow Rates: Up to 300 LPH

➡️ Pressure: Up to 350 bar

➡️ Temperature: -30 °C to 350 °C

➡️ Material: SS316, Hastelloy C, etc.

➡️ Applications: Slurries, viscous fluids, gas-liquid-solid contacting, fast exothermic reactions, long residence time reactions, continuous crystallizations

Slurry Handling Reactors – Continuous Stirred Tank Reactor (CSTR)

Continuous Stirred Tank Reactors (CSTRs) are agitated, tank-like reactors used for continuous chemical processes requiring steady input of reactants and removal of products. They maintain uniform composition and temperature through constant mixing. Ideal for steady-state operations with perfect mixing, they suit large-scale continuous processes involving medium to slow reactions, especially in liquid systems. CSTRs handle solids and viscous fluids efficiently and can be cascaded to mimic plug flow reactor (PFR) behavior.

➡️ Volume: 100 mL to 1,000 L

➡️ Pressure: Up to 350 bar

➡️ Temperature: Up to 500 °C

➡️ Material: SS316, Hastelloy, Inconel, Monel, Nickel, Titanium

➡️ Certifications: ASME, U Stamp, PED, ATEX certified systems

➡️ Custom turnkey solutions: Gas/liquid charging, heating, cooling, catalyst filtration, back pressure regulator, accessories, utilities, instrumentation, PLC with touch panel & SCADA software

➡️ Applications: Catalytic hydrogenation, polymerization, crystallization, fermentation, esterification, saponification, wastewater treatment, oxidation & reduction processes

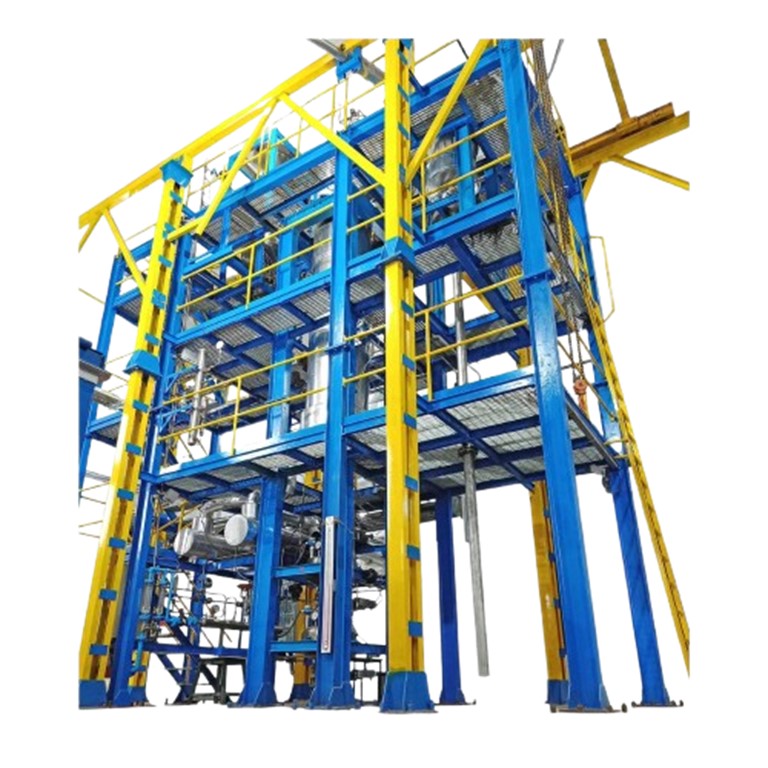

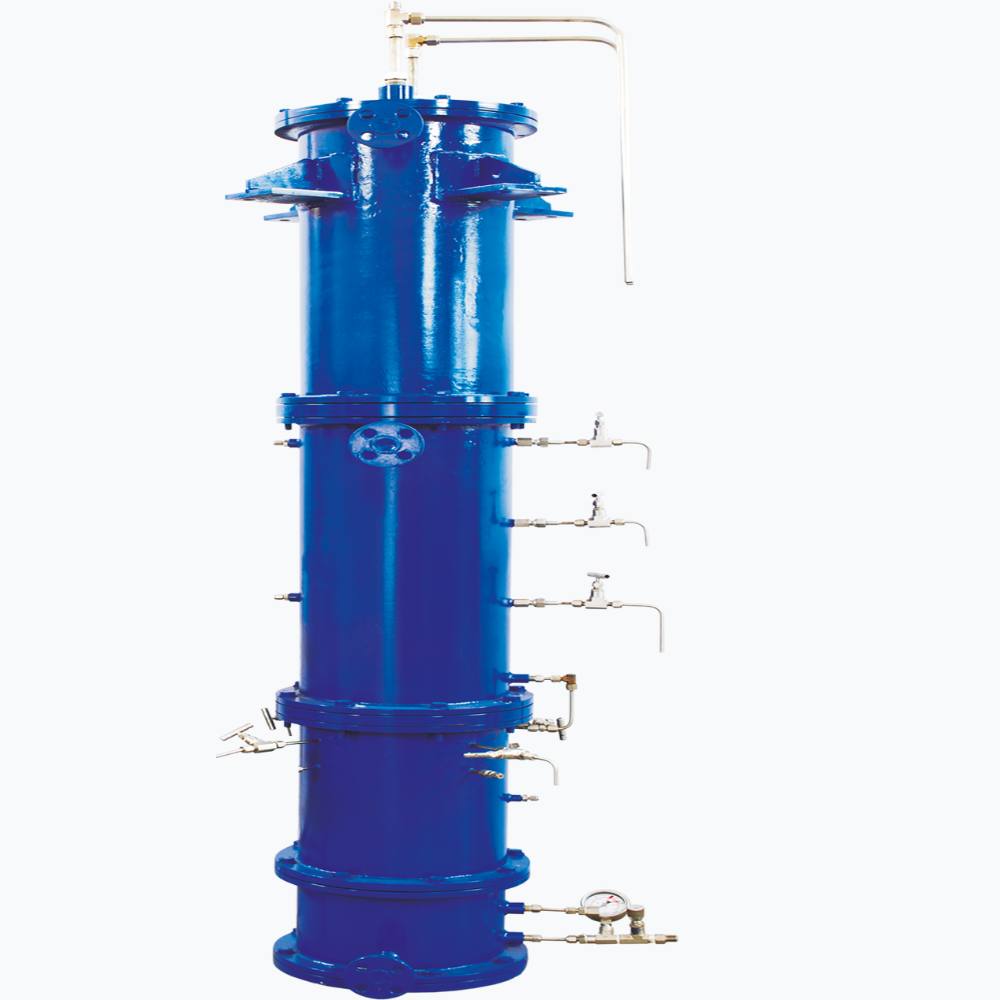

Fixed & Fluidized Bed Reactor

Fixed Bed Reactors consist of a stationary catalyst bed through which reactants in gas or liquid phase flow, usually at high temperatures. Used mainly for catalytic processes, reactions occur in isothermal or adiabatic modes. Common in petrochemical refining, environmental control, and high tonnage continuous processes. Configurations include upflow, downflow, and trickle bed, with options for intercoolers and side reactant injection. Shell-and-tube designs may be used for enhanced heat transfer.

Fluidized Bed Reactors suspend solid particles in gas or liquid flow, improving heat and mass transfer. Ideal for catalytic cracking, gasification, and combustion processes.

PascalFLO™ Pump

The PascalFLO™ Pump is a gas-driven, diaphragm-based pump designed for accurate dosing and pumping of liquids and slurries in continuous flow applications. It operates without the need for controllers on the liquid lines, offering precise flow control. Constructed from SS316 and Hastelloy C, it is suitable for handling aggressive chemicals under pressures up to 100 bar and temperatures up to 350°C. This pump is ideal for processes requiring reliable, leak-free operation in demanding conditions.

➡️ Patented PascalFLO™ innovation controls flow without flow meter or control valve

➡️ Flow Rates: 1 mL/min to 100 LPH

➡️ Pressure: Up to 100 bar

➡️ Temperature: Up to 350 °C

➡️ Material: SS316 & Hastelloy

➡️ Controlled dosing/pumping of any liquid or slurry, independent of temperature, rheology, composition

➡️ Accurate flow control without controllers on liquid lines

➡️ No recalibration needed when changing liquids

➡️ Practically pulseless pumping

➡️ Operated by controlled gas flow