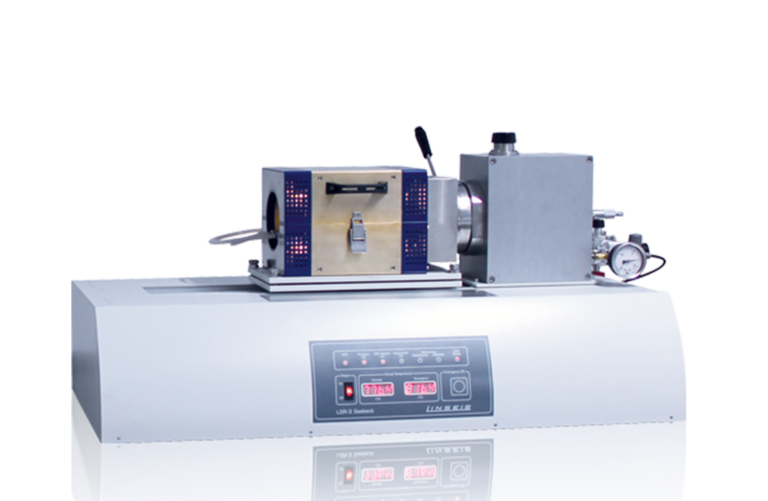

Linseis – LZT Meter

The LZT-Meter from Linseis is a specialized device designed to measure the thermoelectric properties of materials. It combines two key measurement techniques: the Laser Flash Analyzer (LFA) for determining thermal diffusivity and the Seebeck coefficient (LSR) for electrical conductivity. This combination is particularly useful for calculating the figure of merit (ZT) of thermoelectric materials, which is crucial for evaluating their efficiency in energy conversion applications. The LZT-Meter allows for precise testing over a wide temperature range and is applied in industries such as automotive, aerospace, and energy research

LZT Meter

The Linseis LZT Meter is the world’s first commercially available instrument that allows the determination of the thermoelectric Figure of Merrit ZT by means of a combined Laser Flash (LFA 1000) and LSR measurement in a single instrument.

Accordingly, an independent determination of the thermal conductivity by means of a flash method as well as a measurement of the electrical resistance and of the Seebeck-Coefficient (known from the LSR platform) can be carried out with this measuring device.

The advantage is obvious: The integrated design can save both, expensive laboratory space and unnecessary costs for double furnaces, measuring electronics and other equipment. Thus, the LZT-Meter is the ideal solution for research and development applications where the focus is not set on high sample throughput but on measurement quality and cost-efficiency. Because for the complete ZT-characterization of the sample, a single, disk-shaped geometry is completely sufficient.

Advantages of the combined measurement:

- Measurement of a single sample

⚬No geometry error

⚬Same stoichiometry

⚬No problems with further sample preparation

- Identical environmental conditions

⚬Temperature

⚬Humidity

⚬The atmosphere

Furthermore, all well known advantages of the LSR-Platform

- Resistivity measurements of high-resistance samples possible

- Optional Harman measurement

- Camera option

The unit is also available with three different furnaces:

- An infrared furnace (for precise temperature control at very high and low heating rates)

- A low-temperature furnace for measurements down to -100°C

- A high-temperature furnace for measurements up to 1100°C

The supplied software package offers the possibility to evaluate all measurement data in a user-friendly way and to use the optionally integrated Harman ZT model.

Key Features

✔️Only one integrated measuring device is required for a complete ZT characterization

✔️Cost-efficient and space-saving

✔️Thanks to the high-ohm option and variably positionable thermocouples, even the most demanding samples can be reliably measured

✔️Measurements in the temperature range from -100°C to 1100°C are possible using interchangeable furnaces

✔️Direct ZT measurement on legs (Harman method) and modules (impedance spectroscopy)

✔️Thermal conductivity measurement using the LaserFlash method

✔️High-speed infrared furnace for excellent temperature control during measurement and higher sample throughput

✔️Wide range of available thermocouples (temperature range, sheathed, free-standing)

✔️Camera option for high-precision resistivity measurements.

Downloads

IDEAL FOR

The LZT-Meter is ideal for evaluating thermoelectric materials, particularly in the context of measuring the figure of merit (ZT), which is a key performance indicator for energy conversion efficiency. This instrument is designed to perform dual measurements—thermal diffusivity (via the Laser Flash Analyzer, LFA) and electrical conductivity (via the Seebeck coefficient, LSR). These properties are crucial for assessing materials used in thermoelectric generators (TEGs) and Peltier devices, which convert temperature differences into electrical power or use electricity for cooling. The LZT-Meter is particularly useful in energy research, automotive, aerospace, and materials science industries, where it helps optimize materials for efficient thermoelectric applications

FEATURES

MODEL |

LSR-3 PART |

|---|---|

| Temperature range: | Infrared furnace: RT up to 800°C/1100°C Low temperature oven: -100°C to 500°C |

| Measurement method: | Seebeck coefficient: Static DC method / Slope method Electrical resistance: four-point measurement |

| Atmosphere: | Inert, reducing, oxidizing, vacuum Helium gas with low pressure recommended |

| Sample holder: | Vertical clamping between two electrodes Optional adapter for foils and thin layers |

| Sample size (cylinder or rectangle): | 2 to 5 mm base area and max. 23 mm long up to a diameter of 6 mm and a length of max. 23 mm long |

| Sample size round (disc shape): | 10, 12.7, 25.4 mm |

| Measuring distance of the thermocouples: | 4, 6, 8 mm |

| Water cooling: | required |

| Measuring range Seebeck coefficient: | 1µV/K to 250mV/K (static DC method) Accuracy ±7% / Repeatability ±3.5% |

| Measuring range Electrical conductivity: | 0.01 to 2×105 S/cm Accuracy ±10% / Repeatability ±5% |

| Current source: | Low-drift current source from 0 to 160 mA |

| Electrode material: | Nickel (-100 to 500°C) / Platinum (-100 to +1500°C) |

| Thermocouples: | Type K/S/C |

| Heat conductivity | |

| Pulse source: | Nd:YAG laser (25 joules) |

| Pulse duration: | 0.01 to 5ms |

| Detector: | InSb / MCT |

| thermal conductivity | |

| Measuring range: | 0.01 to 1000mm2/s |

| Addon | LSR-4 upgrade |

| DC Harman method: | Direct ZT measurement on thermoelectric legs |

| AC impedance spectroscopy: | Direct ZT measurement on thermoelectric modules (TEG/Peltier module) |

| Temperature range: | -100 to +400°C RT to +400°C |

| Sample holder: | Needle contacts for adiabatic measuring conditions |

| Sample size: | 2 to 5 mm in rectangle and max. 23 mm long up to 6 mm in diameter and max. 23 mm long Modules up to 50mm x 50mm |