Pressure Reactors

Pressure Reactors for high-pressure, high-temperature reactions in process development and scale-up. Offered in multiple MOCs, with varied sizes from lab to production, and standard accessories. Used in petrochemicals, refining, pharma, and specialty chemicals.

Pressure Reactors

Pressure Reactors are used for high-pressure, high-temperature chemical reactions in process development and scale-up applications. They are available in a variety of Materials of Construction (MOCs) with a wide range of options and standard accessories. Sizes range from lab to pilot and production scale. Typical end users include the petrochemicals, refining, pharmaceutical, and specialty chemicals industries.

Stirred Pressure Reactor – Autoclave

A Stirred Pressure Reactor (or Autoclave) is a specialized reactor designed for chemical reactions under elevated pressures and temperatures. A mechanical agitator ensures efficient mixing, enhances mass transfer, and accelerates reaction kinetics, while a jacket or internal cooling coil provides effective heat transfer.

Typically constructed from high-strength, corrosion-resistant materials such as stainless steel or Hastelloy, these vessels are essential in process development and scale-up for operations like hydrogenation, polymerization, and catalytic transformations. They are widely used in the chemical, petrochemical, and pharmaceutical industries, forming a key part of process intensification strategies and supporting both batch and continuous modes.

➡️ Volume: 100 mL to 100 L

➡️ Pressures: Up to 350 bar

➡️ Temperature: Up to 500 °C

➡️ Material: SS-316, Hastelloy, Inconel, Monel, Nickel, Titanium, Zirconium, & Tantalum lined

➡️ Certifications: ASME-U Stamp / PED certified reactors, CE / CSA, Ex-proof / ATEX certified systems

➡️ Automation: High-resolution programmable 10″ touchscreen panel with SCADA software for data logging & wireless remote control

➡️ Auto-cooling System: High-pressure water-based auto-cooling for excellent temperature control & quick cooling from high temperatures

➡️ Head Mounting Options: Removable or fixed head with pneumatic / hydraulic raising, lowering, & tilting

➡️ Stirrer Options: Pitch blade turbine impeller, high mass transfer gas induction impeller, anchor & helix for various applications

➡️ Customization: Available for volume, temperature, pressure, & design

➡️ Applications: Alkylation, Amination, Bromination, Carboxylation, Catalytic Reduction, Chemical Synthesis, Chlorination, Dehydrogenation, Esterification, Ethoxylation, Halogenation, Hydrogenation, Material Synthesis, Methylation, Nitration, Oxidation, Ozonization, Polymerization, Sulphonation, etc.

Parallel Synthesizer

Parallel synthesizers are the next step in scale-up from React-7 models, where larger quantities of typically liquid phase reactions can be handled in parallel mode. Top-mounted stirrers allow viscous reactions, and high temperature and pressure conditions can be safely studied along with corrosive reagents due to a wide variety of Materials of Construction.

These reactors are the best choice for an experimental design program to optimize synthesis conditions and for catalyst screening. Gas pressures can be independently varied for each reactor, and jacketed as well as coil cooling and heating is possible, along with automatic data logging and PID control. Process development teams often use these to close material balance models and evaluate changes in heat and mass transfer from mL to L scales.

➡️ Configuration: Combination of 4 or 6 reactors in parallel, with same or different specifications

➡️ Volume: 100 mL to 2 L

➡️ Pressures: Up to 350 bar for each reactor

➡️ Temperature: Up to 500 °C for each reactor

➡️ Material: SS-316, Hastelloy, Inconel, Monel, Nickel, Titanium, Zirconium, & Tantalum lined

➡️ Certifications: ASME-U Stamp, PED, CE, CSA, Ex-proof, ATEX certified systems

➡️ Automation: High-resolution programmable 10″ touchscreen panel with SCADA software, data logging, & wireless remote control

➡️ Auto-cooling System: High-pressure water-based system for precise temperature control & rapid cooling

➡️ Head Mounting Options: Removable or fixed head with pneumatic / hydraulic raising, lowering, & tilting

➡️ Stirrer Options: Pitch blade turbine impeller, high mass transfer gas induction impeller, anchor, & helix for various applications

➡️ Customization: Available for volume, temperature, pressure, & design

➡️ Applications: Alkylation, Amination, Bromination, Carboxylation, Catalytic Reduction, Chemical Synthesis, Chlorination, Dehydrogenation, Esterification, Ethoxylation, Halogenation, Hydrogenation, Material Synthesis, Methylation, Nitration, Oxidation, Ozonization, Polymerization, Sulphonation, etc.

Parallel Screening Reactors – React – 7 | Magnetic Stirred

The React-7 Magnetic Stirred Parallel Screening Reactor is a compact system designed for simultaneous testing of seven reactions under controlled temperature and pressure. Each reactor typically handles 25 mL and allows independent sampling, with options for SS-316, Hastelloy, or glass construction. The system features magnetic stirring, integrated heating and cooling, and is ideal for catalyst screening, kinetic studies, and process optimization at lab scale.

➡️ Volume: 25 mL × 7 bottom-stirred parallel reactors

➡️ Pressure: Up to 100 bar for each reactor

➡️ Temperature: Up to 200 °C

➡️ Material: SS-316, Hastelloy, & Glass (interchangeable options)

➡️ Design: Very compact and economical for high-throughput screening

Customized Pressure Reactors

Amar manufactures large pressure vessels tailored for scale-up and production needs. These are designed to withstand high pressures and temperatures, available in both stirred and non-stirred configurations.

Heating and cooling options include external jackets, limpets, internal coils, and external loop heat exchangers. Built to global quality standards, they meet certifications like EU-PED and ASME-U Stamp. Magnetic drives and corrosion-resistant materials enable safe handling of toxic and flammable fluids, with customized nozzles and fittings to match specific process requirements.

➡️ Volume: 100 L to 1,000 L custom-built reactors

➡️ Pressures: Up to 100 bar

➡️ Temperature: Up to 350 °C

➡️ Material: SS-316, SS-316L, Hastelloy, Titanium, Monel, Inconel, Zirconium, etc.

➡️ Drive: Zero-leakage magnetic drive couplings

➡️ Certifications: ASME-U Stamp, PED, CE, CSA, Ex-proof, ATEX certified systems

➡️ Skid-mounted system: Includes valves, piping, accessories, control panel, and SCADA software

➡️ Impellers: High mass transfer gas induction impeller & pitch blade turbine impeller

➡️ Applications: Alkylation, Amination, Bromination, Carboxylation, Catalytic Reduction, Chemical Synthesis, Chlorination, Dehydrogenation, Esterification, Ethoxylation, Halogenation, Hydrogenation, Material Synthesis, Methylation, Nitration, Oxidation, Ozonization, Polymerization, Sulphonation, etc.

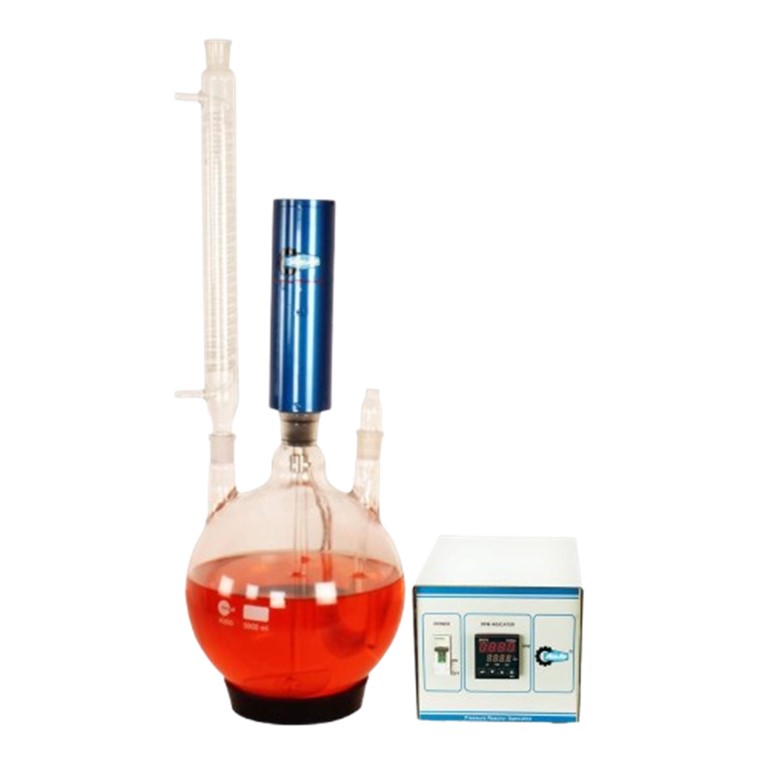

Glass Autoclave

The Glass Autoclaves from Amar are available in 500 mL, 1 L, and 2 L sizes, designed to operate at pressures up to 10 bar and temperatures up to 200 °C. They feature a borosilicate glass cylinder with wetted parts made from SS-316, Tantalum-lined SS, or Hastelloy C, allowing for visual monitoring of reactions. These autoclaves are suitable for applications such as nitration, esterification, oxidation, hydrolysis, Grignard reactions, polymerization, condensation, photochemical reactions, and neutralization processes.

➡️ Volume: 500 mL, 1 L, & 2 L reactors

➡️ Pressures: Up to 10 bar

➡️ Temperatures: Up to 200 °C

➡️ Material: Borosilicate glass cylinder with wetted parts of SS 316, SS with Tantalum Lining, & Hastelloy C

➡️ Applications: Nitration, Sulfonation, Esterification, Oxidation, Hydrolysis, Grignard, Polymerization, Acid-base neutralization, Hydrogenation, Photochemical reaction, Condensation reaction, etc.

High Pressure Vessel

Process systems require high-pressure vessels not only for reactors but also for dosing tanks, buffer vessels, collection pots, distillation column receivers, accumulators, and more.

These vessels can be fabricated in a wide range of Materials of Construction (MOCs) and sizes to support corrosive and toxic duties. Depending on the application, steam jacketing or internal heating/cooling coils can be provided, along with special nozzles and valves designed for slurries or other challenging conditions. All equipment can be manufactured to meet cGMP or CIP standards for pharmaceutical applications and FDA-controlled processes.

➡️ Volume: 25 mL to 100 L

➡️ Pressures: Up to 700 bar

➡️ Temperature: Up to 600 °C

➡️ Material: SS-316, Hastelloy, Inconel, Monel, Nickel, Titanium, Zirconium, Tantalum lined

➡️ Certifications: ASME-U Stamp, PED certified reactors, CE, CSA, Ex-proof, ATEX certified systems

➡️ Automation: High-resolution programmable 10″ touchscreen panel with SCADA software for data logging & wireless remote control

➡️ Applications: Gas/liquid storage, charging, separation & collection, gas hydrate formation, hydrogen induced disbonding tests, soaking of precious stones, etc.

➡️ Customization: Available for pressure vessels above 350 bar or volume over 100 L

Acid Digestion Bomb

The Acid Digestion Bomb from Amar is designed for dissolving inorganic and organic samples using strong acids or alkalis. It offers volumes from 50 mL to 750 mL and operates at pressures up to 200 bar and temperatures up to 250 °C. Constructed from SS-316 with a PTFE liner and cap, it ensures resistance to aggressive chemicals and is ideal for high-pressure digestion processes.

➡️ Volume: 50 mL to 750 mL

➡️ Pressure: Up to 200 bar

➡️ Temperature: Up to 250 °C

➡️ Material: SS-316 with PTFE liner and cap

➡️ Applications: For dissolving or digesting inorganic or organic samples in strong acids or alkalis

➡️ Feature: Microwaveable digestion bombs

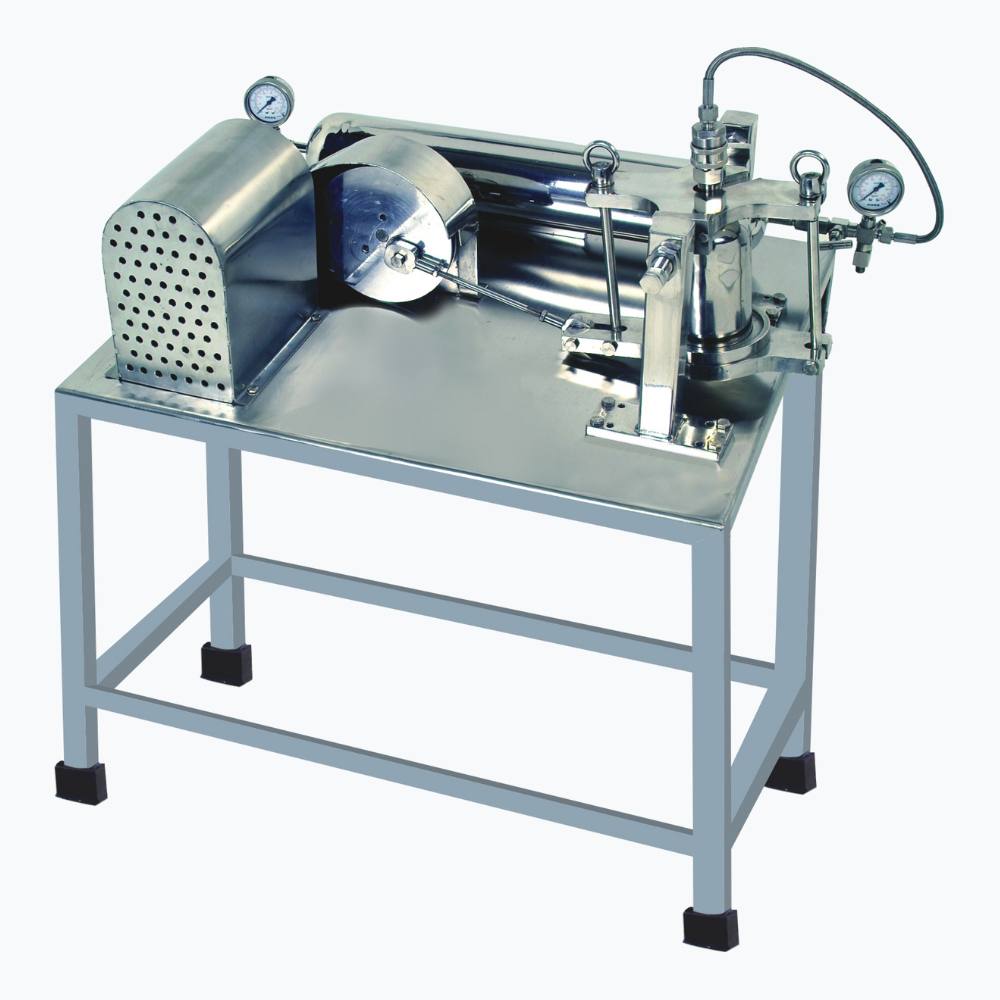

Shaker Hydrogenator

A Shaker Hydrogenator is a laboratory-scale reactor used for catalytic hydrogenation. It features a pressure vessel that holds the liquid substrate, catalyst, and hydrogen gas, while a mechanical shaking mechanism ensures effective mixing. This classic design is ideal for small-scale hydrogenations in R&D, such as reducing double bonds, nitro groups, or aromatic rings. Its simplicity and efficiency make it suitable for exploratory synthesis and catalyst testing.

➡️ Volume: 500 mL, 1 L & 2 L interchangeable reactors

➡️ Pressure: Up to 20 bar

➡️ Temperature: Up to 200 °C

➡️ Material: SS-316, Hastelloy C, & Glass (interchangeable)

➡️ Applications: Synthesizing or modifying organic compounds by catalytic hydrogenation and studying catalyst activity

Magnetic Drive Coupling & Mixer

The Magnetic Drive Couplings & Mixers are designed for leak-proof agitation in high-pressure and high-vacuum applications, with torques up to 1,000 Nm and speeds up to 3,000 RPM. Suitable for reactors from 50 mL to 10,000 L, they operate at pressures up to 700 bar and temperatures up to 200 °C (extendable to 500 °C with cooling). Constructed in materials like SS-316, Hastelloy C, and Inconel, they are ideal for both metallic and glass reactors, with options for inline motors, various impellers, and customized neck sizes.

➡️ For high-pressure applications up to 700 bar

➡️ High torque magnetic drives from 1 to 1,000 Nm

➡️ Speeds up to 3,000 RPM

➡️ Materials: SS316, Hastelloy C, Inconel, etc.

➡️ Compact inline motor & magnetic drive for 50 mL – 10,000 L reactors

➡️ Custom-built agitator with magnetic drive, motor, shaft, & impeller

➡️ Available for 100 mL to 100 L round bottom flask / glass reactors

➡️ Can withstand full vacuum during continuous distillation

➡️ Temperature: up to 200 °C, or 500 °C with cooling jacket

➡️ Available in neck sizes: B24, B29, B34, B45, etc.