Linseis – Thermal Interface Material Tester (TIM-Tester)

Waste heat management, thermal runaway protection in batteries and electronic packaging is becoming more and more important as power densities of these devices increase. Thermal management of these complex systems is not trivial and requires a fundamental understanding of how components and interface materials work together to shed heat.

Thermal Interface Material Tester (TIM-Tester)

LINSEIS Thermal Interface Material Tester (TIM-Tester) is the perfect solution for thermal management optimization of these complex systems.

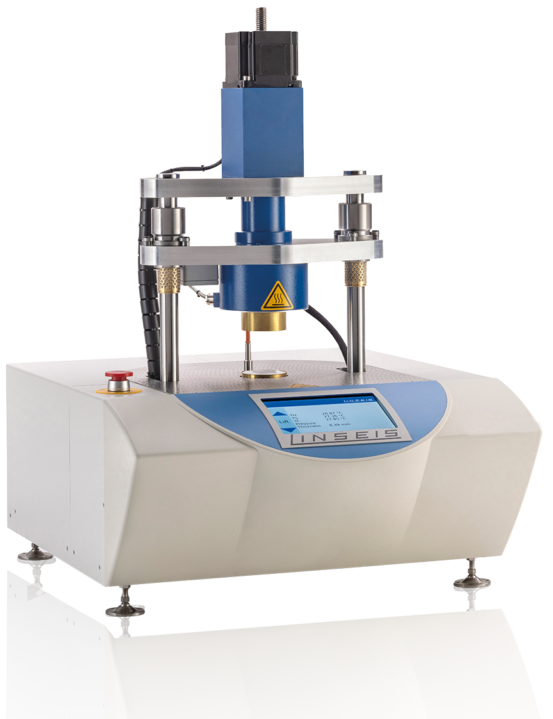

The TIM Tester measures the thermal impedance of sample materials and identifies an apparent thermal conductivity for a wide range of materials from liquid compounds and pastes to hard solid materials. The approach is consistent with the ASTM D5470 – standard.

✔️Automatic pressure adjustment using electric actor (up to 10 MPa)

✔️Automatic thickness determination using high resolution LVDT

✔️Instruments working according to ASTM D5470

✔️Full integrated, software controlled device

Thermal interface materials such as thermal fluids, thermal pastes (greases), phase change materials (PCM), solders or resilient thermal conductors are tested automatically by applying a pressure of up to 10 MPa (for ø 25 mm sample) and temperature of up to 300°C at the hot side.

The software interface allows the instrument to be operated automatically over a wide temperature and pressure range, while all test parameters are recorded in real time. This allows the user the freedom to fully explore an experimental design space for materials optimization. The sample holder is designed with sample size and shape flexibility in mind to accommodate actual size parts.

Typical samples include solids, pastes, pads and more. Different meter bars for varying applications (depending on thermal impedance of the sample materials and temperature range).

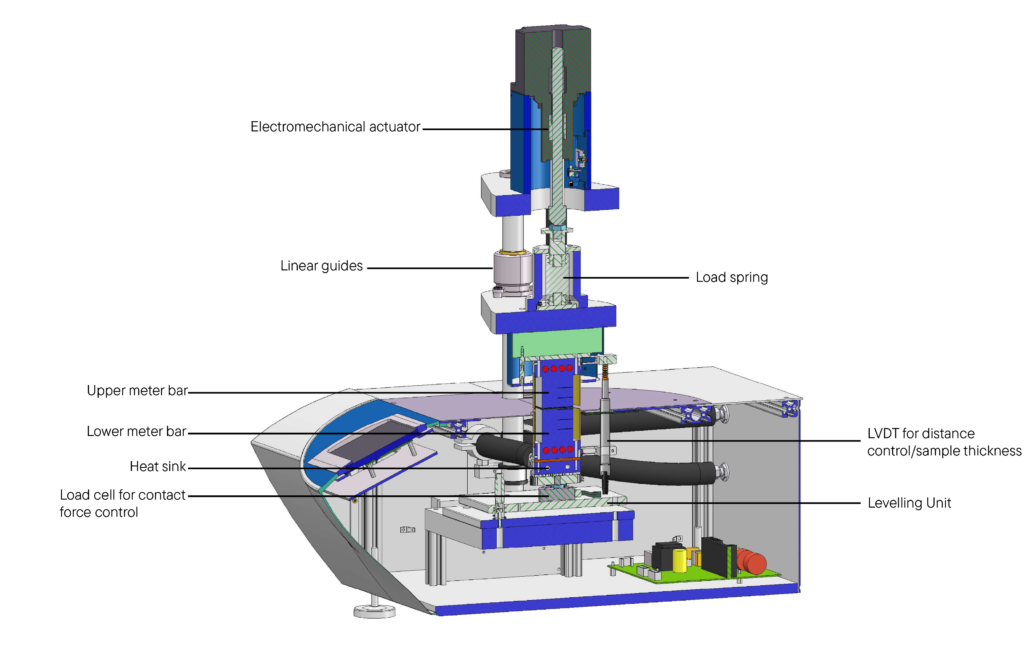

Measuring Principle

A sample is positioned between a hot and a cold meter bar, where the hot meter bar is connected to a regulated heating stage and the cold meter bar is connected to a thermostatically control¬led, liquid cooled heat sink. The contact pressure on the sample can be automatically adjusted with an integrated electric actor (in terms of pressure stability over temperature). The sample dimension (thickness) can either be entered manually or can be measured (and controlled) using an integrated sensor.

The heat flux through the sample is measured using several temperature sensors which are located in a known distance inside of each of the meter bars. The thermal impedance can be obtained from the temperature drop caused by the sample material using its geometry for the calculation. For obtaining the apparent thermal conductivity, the thermal impedance for a single and a multiple layered specimen can be plotted against the thickness of the respective specimen.

Downloads

IDEAL FOR

The Thermal Interface Material Tester (TIM-Tester) from Linseis is ideal for characterizing and evaluating thermal interface materials (TIMs). These materials are crucial for efficient heat transfer in electronics, batteries, and other high-power density devices. The tester is specifically designed to measure:

- Thermal Conductivity and Resistance: It provides precise data on how well a TIM conducts heat and its resistance to heat flow.

- Real-world Operating Conditions: It can simulate actual usage scenarios by applying different temperatures, pressures, and surface finishes, ensuring the results reflect practical performance.

- Optimization of Interfaces: It helps in determining the optimal combination of materials and conditions (e.g., contact pressure) for minimizing thermal resistance.

This device is commonly used in R&D and quality control for industries like electronics, automotive, aerospace, and energy storage, where managing heat efficiently is critical to performance and reliability.

FEATURES

MODEL |

TIM-TESTER |

|---|---|

| Temperature range: | -30°C to 300°C* |

| Sample size: | Round: ø 20 mm, 25 mm, 40 mm Rectangular: 20 mm x 20 mm, 25 mm x 25 mm, 40 x 40 mm Other sizes on request |

| Sample thickness: | 0.01 mm to 8 mm (up to 20 mm possible) |

| Measuring range of the sample: | 0.1 – 50 W/mK |

| Range of sample resistance: | 0.01 – 8.0 K/W |

| Contact pressure range: | 0 to 16 MPa (depending on sample size and shape) From round ø 20mm (up to 16 MPa) to ø 40 mm (up to 4 MPa) and rectangular 20mm x 20mm (up to 8 MPa) |

| Force options: | 1 kN, 2 kN, 5 kN |

| Material of the measuring rods: | Aluminium, copper, brass (others on request) |

| Software plugins: | Thickness modulation Temperature change Quality management tool |

| Cooling options: | Standard water cooling unit, Intracooler 600 (-20°C cold side)**, Intracooler 1000 (-30°C cold side)** |

| Power supply: | 110/115/220/230 VAC 50/60 Hz |

| * Under optimum conditions ** Lowest counter bar temperature on the cold side under optimum conditions |

|