Nabertherm’s Furnaces for Special Applications are expertly designed to meet the unique demands of specialized laboratory processes. Whether for precise fire assay, controlled gradient annealing, rapid fast firing, or handling molten materials with tilting furnaces, these units combine reliability, precision, and versatility to support advanced research and testing needs.

Furnaces for Special Applications

Nabertherm’s special application furnaces include fire assay, gradient annealing, fast firing, and tilting laboratory furnaces, designed for precise and efficient lab processes.

Category Muffle Furnaces

Brand: Nabertherm GmbH

Description

Furnaces for Special Applications

Precision Solutions for Unique Laboratory Processes

Fire Assay/Cupellation Furnaces up to 1300 °C

Cupellation is a process to separate precious metals like gold or silver from alloys with base metals, releasing aggressive gases that can damage furnace insulation and heating elements. The N ../13 CUP cupellation furnaces are specially designed to meet these demanding conditions, featuring a ceramic muffle that protects the heating elements and insulation. A fresh-air and exhaust system safely directs gases to the exhaust hood, which connects to the customer’s exhaust system. The design is maintenance-friendly, allowing easy replacement of wear parts like the ceramic muffle and heating elements. Models N 4/13 CUP and N 10/13 CUP are tabletop furnaces for cupellation, while the N 30/13 CUP and pit-type S 73/HS are suitable for crucible melting due to their high chamber design.

Gradient or Lab Strand Annealing Furnaces up to 1300 °C

The gradient furnace GR 1300/13 features a furnace chamber divided into six equal control zones, each with separately controlled temperatures. Typically, charging is done from the side via a parallel swivel door, allowing a maximum temperature gradient of 400 °C over a heated length of 1300 mm. On request, it can be configured as a lab strand annealing furnace with a second door on the opposite side. Using the included fiber separators, charging can also be performed from the top.

🟨 Tmax 1300 °C

🟨 Heated length: 1300 mm

🟨 Heating elements on support tubes for free heat radiation

🟨 Dual shell housing of textured stainless steel with fan cooling for low surface temperature

🟨 Exclusive use of insulation materials without EC Regulation No. 1272/2008 (CLP) classification

🟨 Charging from the top or right side door

🟨 Gas damper suspension on lid

🟨 Separate control of six heating zones (each 160 mm)

🟨 Temperature gradient of 400 °C over entire kiln length, each zone individually controlled

🟨 Fiber separators divide chamber into six equal sections

🟨 Controller: H1700

🟨 Defined application within operating instructions

Fast-Firing Furnaces up to 1300 °C

These fast-firing furnaces are ideal for simulating typical fast-firing processes up to a maximum temperature of 1300 °C. Their combination of high performance, low thermal mass, and powerful cooling fans enables cycle times from cold to cold of up to 35 minutes, with an opening temperature of approximately 300 °C.

🟨 Tmax 1300 °C

🟨 Ceramic grid tubes for charge support

🟨 Floor and lid heating with two-zone control

🟨 Special heating element layout for optimum temperature uniformity

🟨 Rapid switching cycles for precise temperature control

🟨 Dual shell ventilated stainless steel housing for low surface temperature and high stability

🟨 Use of insulation materials without EC Regulation No 1272/2008 (CLP) classification (no carcinogenic RCF)

🟨 Integrated programmable cooling fans for charge and housing cooling

🟨 Programmable lid opening (~60 mm) for faster cooling without fan

🟨 Thermocouple type S for top and bottom zones

🟨 Castors for easy moving

🟨 Controller with touch operation P570 (50 programs, 40 segments each)

🟨 NTLog Basic for process data recording via USB

🟨 Defined application within operating instructions

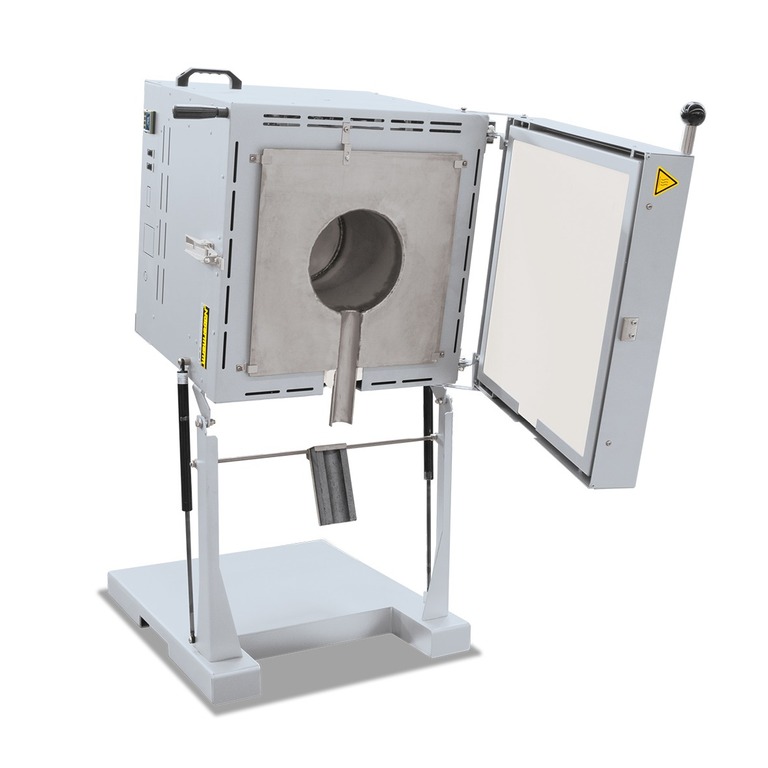

Laboratory Tilting Furnaces K/KC (electrically heated)

These compact tilting furnaces for melting non-ferrous metals and alloys offer unique technical advantages. Designed as tabletop models, they suit various laboratory applications. Features include a counterbalanced hinge with shock absorbers and a front spout (except KC 4/14) for precise melt dosing. Available for chamber temperatures of 1000 °C, 1300 °C, or 1400 °C.

🟨 Tmax: 1000 °C, 1300 °C, or 1400 °C

🟨 Crucible sizes: 0.75 L, 1.5 L, or 3 L

🟨 Dual shell ventilated housing made of textured stainless steel for low surface temperature & high stability

🟨 Insulation materials exclude alumino silicate wool (RCF), per EC Regulation No 1272/2008 (CLP)

🟨 Crucible with integrated clay-graphite pouring spout included

🟨 Additional spout (except KC 4/14) for precise pouring

🟨 Compact bench-top design with tilting system and gas damper for easy emptying

🟨 Hinged insulated lid opens when pouring

🟨 Controller: R8 (3508 for KC)

🟨 Defined application within operating instructions constraints