Linseis | Dielectric analysis (DEA)

Dielectric analysis (DEA) can be used to determine the curing behavior and viscosity of thermal and UV-curing materials. This allows important information to be obtained about the chemistry, composition, kinetics and other physical parameters of the materials under investigation.

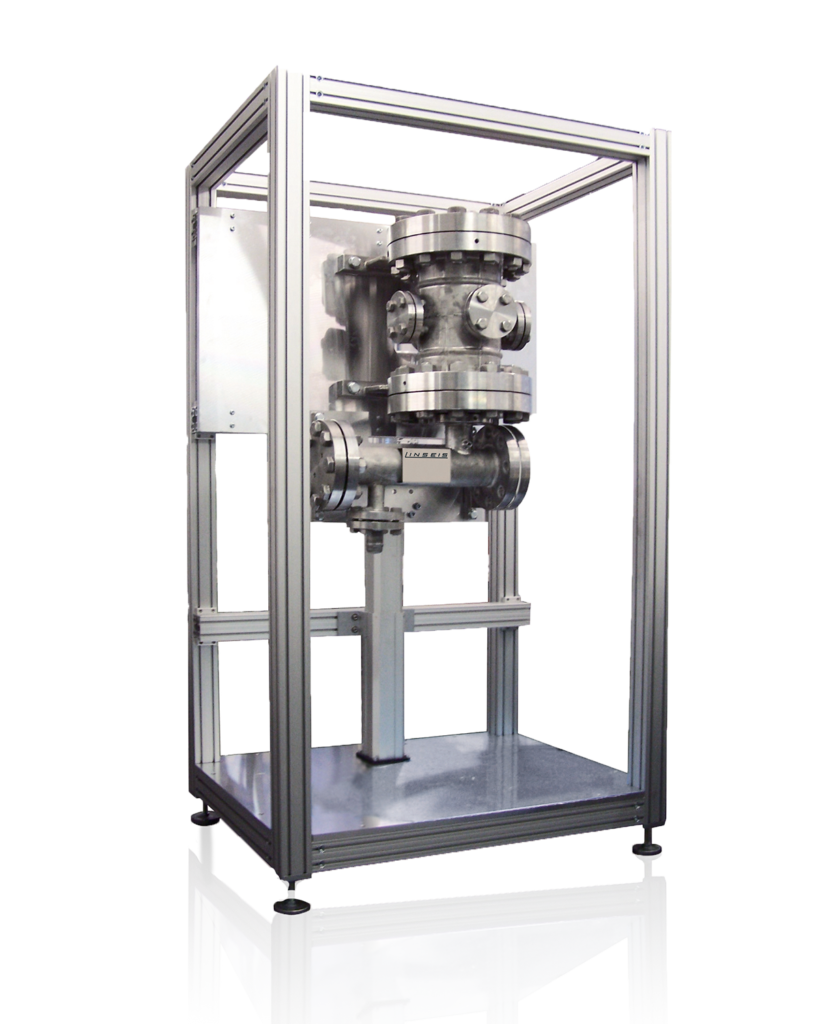

LINSEIS - Dielectric analysis (DEA)

Dielectric analysis is the only analytical method for R&D, quality control and production that provides quantitative information that can be applied 1:1 to all practical aspects of polymer processing. The high-quality Linseis DEA devices, sensors and software can be used in a very flexible and user-friendly way. The Linseis DEA is a perfect tool for polymer characterization and optimization of end products.

Applications

- Optimization of polymer formulations

- Reaction rates of curing reactions

- Diffusion studies

- Curing and process development/monitoring

- Material characterization

- Statistical quality control

Materials

- Epoxy resins

- Polyurethanes

- Polyester

- Polystyrene

- Composites and laminates

- Bulk Sheet Molding Compounds

- Paints and varnishes

Downloads

IDEAL FOR

Linseis Dielectric Analysis (DEA) is an advanced technique used to study the dielectric properties of materials, especially polymers, ceramics, and other insulative materials. It is ideal for several applications, including:

- Characterizing Polymers and Composites: Analyzes electrical behavior of polymers and polymer blends, providing insights into dielectric properties, essential for understanding material performance in various applications.

- Determining Material Properties: Measures key properties like dielectric constant, dielectric loss, and relaxation behavior, helping to understand how materials behave under electrical fields in electrical and electronic devices.

- Thermal and Structural Analysis: Assesses thermal and structural transitions such as glass transition temperature (Tg) and crystallization processes, aiding in the development and optimization of new materials.

- Monitoring Curing Processes: Used in the electronics and automotive industries to monitor the curing process of composite materials, optimizing production conditions and ensuring consistent material properties.

- Identifying Molecular Mobility: Studies molecular dynamics, mobility, and transitions in polymers, helping predict material behavior under different environmental conditions.

- Analyzing Conductivity: Provides data on electrical conductivity and permittivity, crucial for designing insulators and materials used in electronic applications.

FEATURES

MODEL |

DEA |

|---|---|

| Physical | |

| Dimensions: | 17” W x 16” L x 3.25” H |

| Weight: | 16 lbs |

| Electrics | |

| Power: | 100 VAC – 240 VAC, 50/60 Hz automatically switching universal input, 4 A max |

| Communication: | RS-232C, USB with adapter |