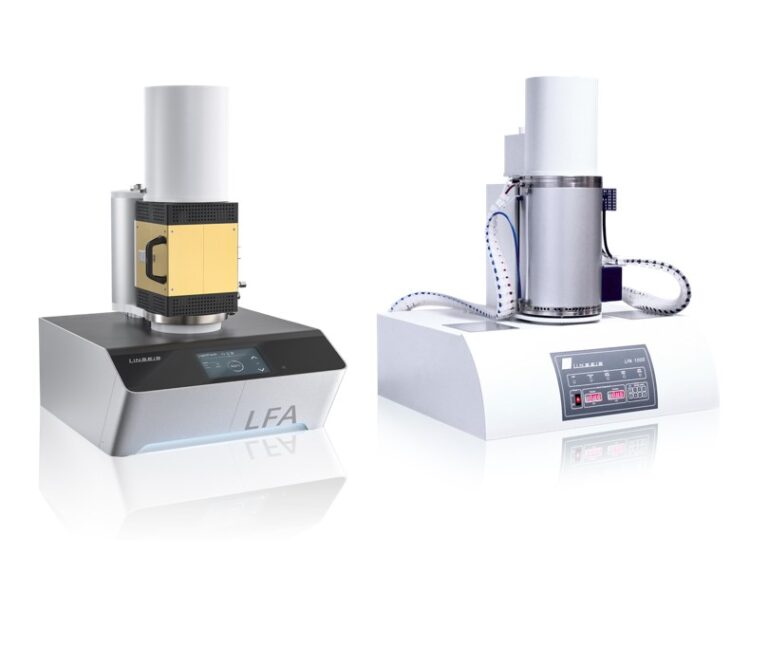

Linseis – Laser Flash Analyzer – LFA

The Laser Flash Analyzer (LFA) is a high-precision instrument for measuring the thermal conductivity and thermal diffusivity of materials.

The LFA method is based on the principle that a short laser pulse is emitted onto the surface of a sample, causing a temperature rise to be measured on the back of the sample.

This time-temperature curve makes it possible to determine important thermophysical properties such as specific heat, thermal conductivity and thermal diffusivity.

IDEAL FOR

This method is particularly important for the characterization of thermal properties in research and industry.

FEATURES

In the LFA method, the sample is first heated homogeneously to ensure uniform thermal conditions.

A laser pulse hits the sample surface and generates a short, intense heating.

This heating spreads through the sample and the temperature change on the back of the sample is measured using an infrared detector.

This data is recorded and analyzed to determine the thermal conductivity (λ), the thermal diffusivity (α) and the specific heat capacity (cp) of the sample.

Mathematical modeling:

The evaluation of the data is based on the solution of the heat conduction equation:

∂T/∂t=α∇2T

Here is T the temperature, t

the time and α the thermal diffusivity.

By adapting the measured temperature curves to this model, precise values for the thermophysical properties of the sample can be determined.