Linseis – Periodic Laser Heating (PLH)

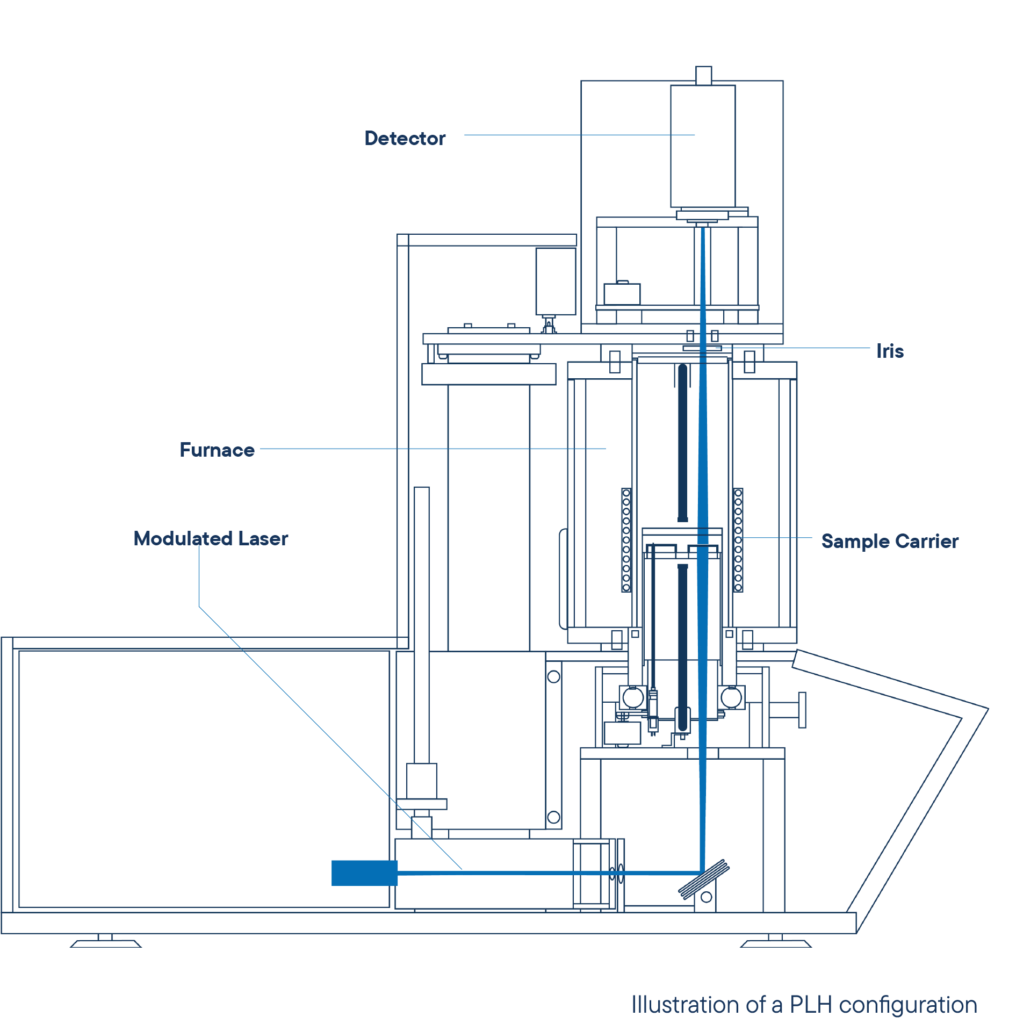

The PLH from Linseis is a precise and efficient system designed for measuring thermal conductivity and diffusivity of various materials. It uses the Laser Flash Method (LFA) to rapidly assess these properties, offering high accuracy in research and quality control. The system features a powerful laser for initiating the heat pulse and specialized sensors for capturing the thermal response, providing valuable data for material characterization across a wide range of industries. The PLH is user-friendly, versatile, and optimized for both laboratory and industrial environments, making it ideal for applications in materials science, electronics, and energy sectors.

Periodic Laser Heating (PLH)

The characterization of micrometer materials is a critical issue today due to ongoing R&D for new technologies, such as battery and hydrogen applications, as well as miniaturization efforts.

Due to the large surface to volume ratio, these types of materials need to be studied separately from bulk materials, but sample preparation and measurements can be very challenging.

In addition to our well-established laser flash technique, the PLH setup allows us to extend the measurement range of our non-destructive optical instruments in terms of thickness and thermal transport properties.

High-Precision Thermal Characterization for Diverse Materials

The PLH has been developed and optimized to characterize samples with high accuracy over a measurement range of sample thickness from 10 μm to 500 μm and a thermal diffusivity range of 0.01 – 2000 mm²/s.

The system can handle a wide range of materials. It is possible to measure samples with semiconducting behavior as well as metals, ceramics or polymers. Typical applications include freestanding films and membranes for the battery and hydrogen industries.

Downloads

IDEAL FOR

The PLH (Laser Flash Method) from Linseis is ideal for accurately measuring the thermal conductivity and thermal diffusivity of various materials. It is particularly suited for applications in:

- Materials Science: It helps researchers in studying the thermal properties of materials, which is essential for understanding their performance in different environmental conditions.

- Electronics: Used to assess materials used in electronic components, ensuring efficient heat management and device reliability.

- Energy Sector: The PLH is valuable for testing materials used in energy applications, such as insulation materials, batteries, and thermoelectric devices.

- Industrial Quality Control: The system is widely used in manufacturing settings to ensure the thermal properties of materials meet specific requirements.

Its high precision and versatility make it a go-to tool for both research labs and industrial environments that need reliable and efficient thermal property testing.

FEATURES

MODEL |

PLH |

|---|---|

| Temperature range: | RT up to 300°C |

| Heating rate: | 0.01 to 20 °C/min |

| Sample dimensions: | Ø 3, 6, 10, 12.7 or 25.4 mm Square 5×5, 10×10 or 20×20 mm |

| Sample thickness: | 10 – 500 μm |

| Sample robot: | Robot with 3 or 6 samples |

| Laser source: | CW diode laser up to 5 W Wavelength: 450 nm |

| Thermal diffusivity: | 0.01 to 2000 mm²/s (depending on the thickness) |

| Accuracy: | ±5% |

| Repeatability: | ±5% |

| Footprint: | 550 x 600 x 680 mm 21.6 x 23.6 x 26.7 inches |

| STM standards LFA: ASTM E-1461, DIN 30905 and DIN EN 821 ASTM standards PLH: JIS R 7240:2018 & ISO: 20007:2017 |

|