Linseis – Thin Film Analysis (TFA)

The Linseis Thin Film Analyzer (TFA) is a high-precision instrument designed for measuring the thermal and electrical properties of thin films. It is ideal for analyzing thermal conductivity, specific heat, and Seebeck coefficient, as well as electrical resistivity, Hall effect, and charge carrier mobility. This device uses pre-structured measurement chips with advanced techniques like the 3-Omega method and Van-der-Pauw configuration, enabling comprehensive material characterization. It supports diverse deposition methods such as PVD, CVD, and inkjet printing, making it suitable for applications in semiconductors, energy, and material research.

Linseis - Thin Film Analysis (TFA)

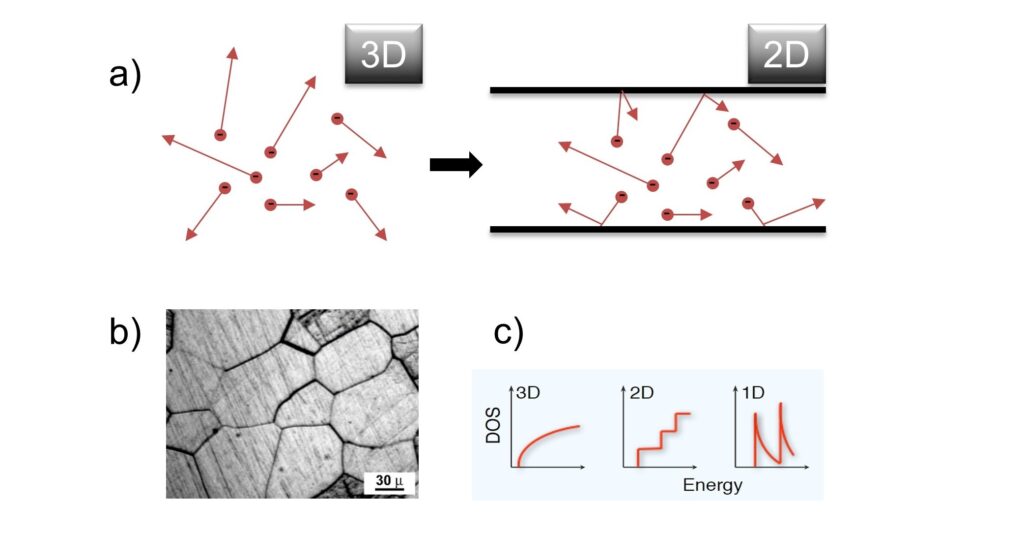

Physical properties of thin films differ from bulk material, as parasitic surface effects are much stronger due to smaller dimensions and high aspect ratios!

- Increasing influence of surface scattering (a)

- Additional boundary scattering (b)

- Quantum confinement for very thin layers (c)

The LINSEIS Thin Film Analyzer is the perfect tool to characterize a broad range of thin film samples in an extremely comfortable and fast way. It is an easy to use, single stand alone system and delivers highest quality results using a patent pending measurement design.

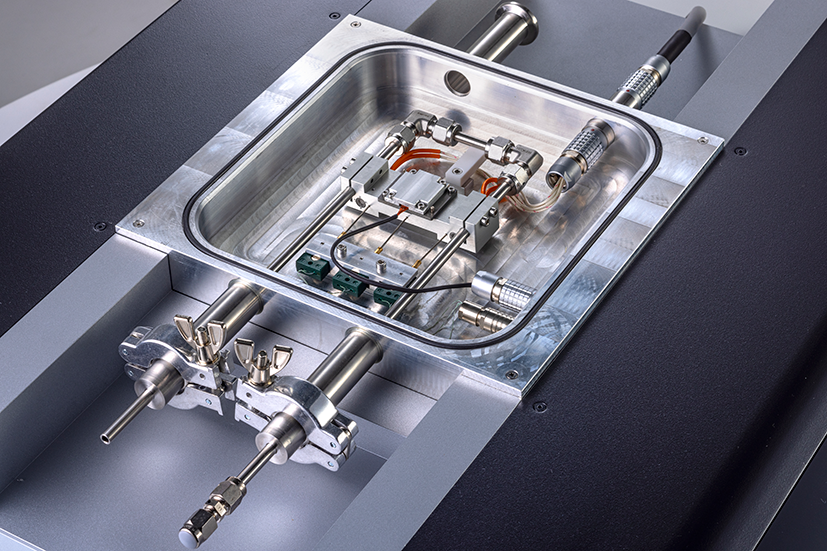

Components of the TFA

The basic setup consists of a measurement chip on which the sample can be easily deposited, and the measurement chamber to provide the required environmental conditions. Depending on the application, the setup can be utilized with a Lock-In amplifier and / or a strong electric magnet. The measurements are usually taken under UHV and the samples temperature can be controlled between -160°C and 280°C during the measurement using LN2 and powerful heaters.

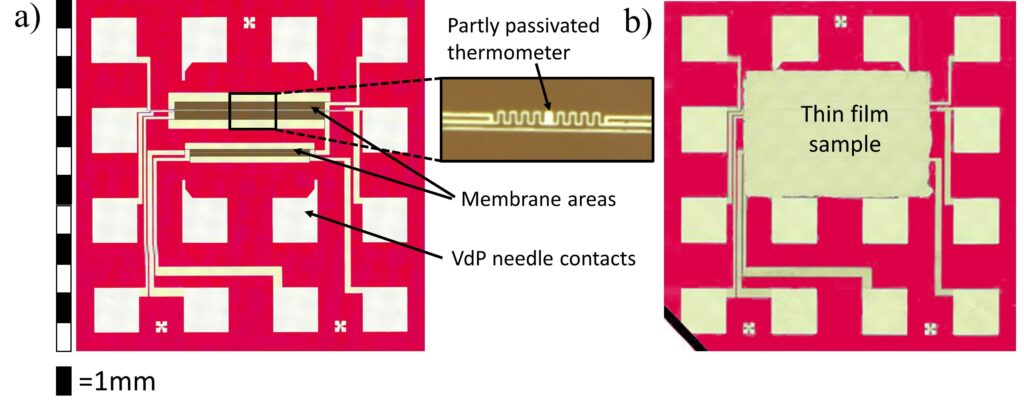

Pre structured measuring chips

The chip is combining the 3 Omega measurement technique for the thermal conductivity measurement with a 4-point Van-der-Pauw setup for the determination of the electrical transport properties.

The Seebeck coefficient can be measured using additional resistance thermometers located near the Van-der-Pauw electrodes. For an easy sample preparation either a strip off foil mask or a metal shadow mask can be used.

This configuration allows for a nearly simultaneous characterization of a sample which has been prepared by either PVD (e.g. thermal evaporation, sputtering, MBE), CVD (e.g. ALD), spin coating, drop casting or ink-jet printing in one step.

The big advantage of this system is the simultaneous determination of a broad range of physical properties within one measurement run. All measurements are take in the same (in-plane) direction and are very comparable.

Special features

- High-quality and user-friendly measuring system for thin layers (in the nm to µm range).

- Enables temperature-dependent measurements from -160°C to +280°C.

- Easy sample preparation and handling.

- Chip-based measuring device with fully integrated, pre-structured chips as consumables.

- Designed for maximum flexibility (material, thickness, resistance, deposition methods).

- All measurements are performed in a single measurement run on the same sample and in the same direction.

- Semiconductor samples as well as metals, ceramics or organic materials can be measured.

Downloads

IDEAL FOR

The Linseis Thin Film Analyzer (TFA) is ideal for applications that require precise thermal and electrical property measurements in thin films and layered materials. Key applications include:

- Semiconductors and Electronics: Characterizing thermal conductivity, electrical resistivity, and carrier mobility in microelectronic devices.

- Energy Conversion: Evaluating thermoelectric materials by measuring the Seebeck coefficient and other energy-related properties.

- Advanced Materials Research: Analyzing films created using PVD, CVD, or inkjet printing for various technological applications.

- Material Development: Testing and optimization of thin films used in batteries, sensors, and photovoltaic devices

Its versatility in handling diverse materials and advanced deposition methods makes it valuable for R&D in industrial and academic settings.

FEATURES

MODEL |

TFA – THIN FILM ANALYZER |

|---|---|

| Temperature range: | RT to 280°C -160°C to 280°C |

| Sample thickness: | From 5 nm to 25 µm (depending on sample) |

| Measuring principle: | Chip-based (pre-structured measuring chips, 24 pieces per box) |

| Separation techniques: | Among others: PVD (sputtering, vaporisation), ALD, spin coating, ink-jet printing and many more |

| Measured parameters: | Thermal conductivity (3 Omega) |

| Heat capacity | |

| Optional: | Electrical conductivity / specific resistance Hall constant / mobility / charge carrier density (electromagnet up to 1 T or permanent magnet with 0.5 T) |

| Vacuum: | ~10E-4mbar |

| Electronics: | Integrated |

| Interface: | USB |

| Measuring range | |

| Thermal conductivity: | 0.05 to 200 W/m∙K 3 Omega method, hot-strip method (in-plane measurement) |

| Electrical conductivity: | 0.05 to 1 ∙ 106 S/cm Van der Pauw four-probe measurement |

| Seebeck coefficient: | 5 to 2500 μV/K |

| Repeatability & Accuracy | |

| Thermal conductivity: | ± 3% (for most materials) ± 10% (for most materials) |

| Resistivity: | ± 3% (for most materials) ± 6% (for most materials) |

| Seebeck coefficient: | ± 5% (for most materials) ± 7% (for most materials) |