Nabertherm’s Ovens and Forced Convection Furnaces up to 850 °C are engineered for precise and uniform heat treatment processes. Models like the NA(T) series feature high-performance air circulation, ensuring optimal temperature uniformity throughout the workspace. These furnaces are suitable for applications such as drying, curing, tempering, and debinding. The sealed forced convection chamber furnaces are designed for processes requiring a protective gas atmosphere, offering flexibility for various heat treatment needs. Additionally, tabletop designs provide compact solutions without compromising performance, making them ideal for laboratory environments.

Ovens and Forced Convection Furnaces up to 850 °C

Ovens and Forced Convection Furnaces up to 850 °C are designed for uniform heating and reliable temperature control in laboratory and industrial applications. Their forced convection system ensures efficient heat distribution, making them ideal for drying, curing, and heat treatment processes.

Category Muffle Furnaces

Brand: Nabertherm GmbH

Description

Ovens and Forced Convection Furnaces up to 850 °C

Efficient heat treatment for drying, curing, and thermal processing up to 850 °C.

Ovens (Electrically Heated)

With their maximum working temperature of up to 300 °C and forced air circulation, the ovens achieve a very good temperature uniformity. They can be used for various applications such as e.g. drying, sterilizing, or warm storing. Short delivery times from stock are ensured for standard models.

🟨 Tmax 300 °C | Working range: +20 °C above room temp to 300 °C

🟨 Models TR 60–TR 420 (tabletop) | TR 450–TR 1050 (floor-standing)

🟨 Forced air circulation ensures ±5 °C uniformity (DIN 17052-1)

🟨 Stainless steel housing and rust-resistant chamber (Alloy 304)

🟨 Multi-layer loading with removable grids

🟨 Quick-release doors: swing for smaller models, double for larger

🟨 Transport castors on TR 800 & TR 1050

🟨 Adjustable exhaust, controlled from front

🟨 PID microprocessor control with self-diagnosis

🟨 No RCF insulation – compliant with EC Regulation 1272/2008

🟨 Controller R8 | Low-noise solid state relays

🟨 NTLog Basic for USB data logging

🟨 Freeware: NTEdit, NTGraph, and MyNabertherm App

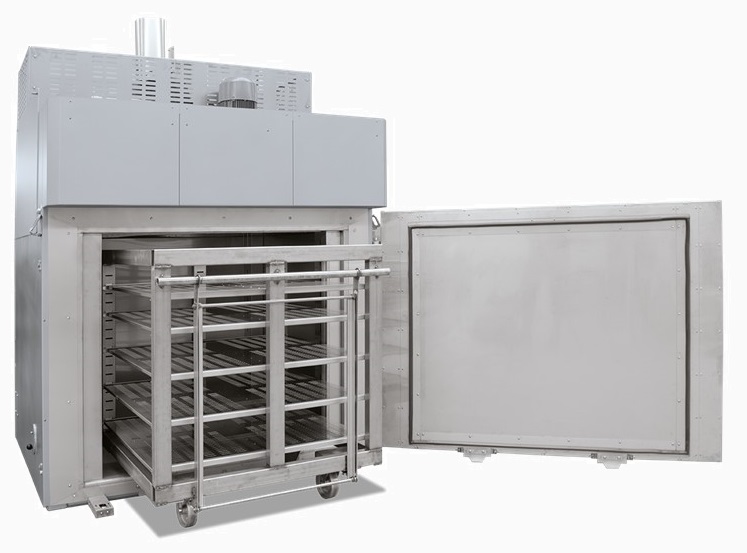

Chamber Ovens up to 260 °C

The chamber ovens of the KTR range can be used for complex drying processes and heat treatment of charges up to an application temperature of 260 °C. The high-performance air circulation enables optimum temperature uniformity throughout the work space. A wide range of accessories allows the chamber ovens to be modified to meet specific process requirements.

🟨 Tmax 260 °C

🟨 Electrically heated or gas-fired (direct/indirect with hot air injection)

🟨 Temperature uniformity up to ±3 °C (DIN 17052-1, no track cutouts)

🟨 Mineral wool insulation keeps exterior < 25 °C above ambient

🟨 No RCF insulation – fully CLP-compliant

🟨 High air exchange for fast drying

🟨 Double-wing door for models KTR 2300+

🟨 Over-temperature limiter to protect furnace/load

🟨 Controller B500 (5 programs × 4 segments)

🟨 Defined application per operating instructions

🟨 NTLog Basic for USB data logging

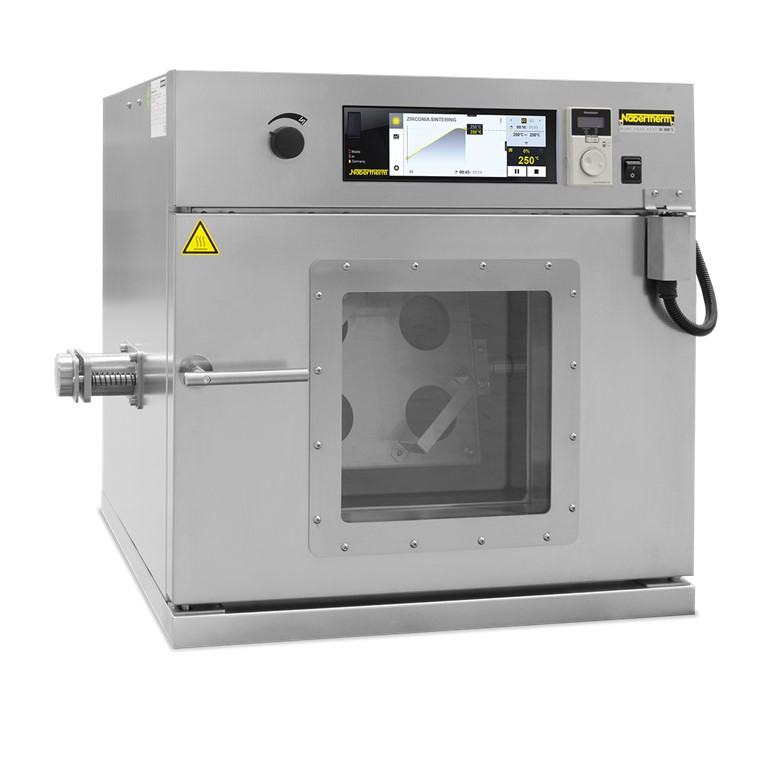

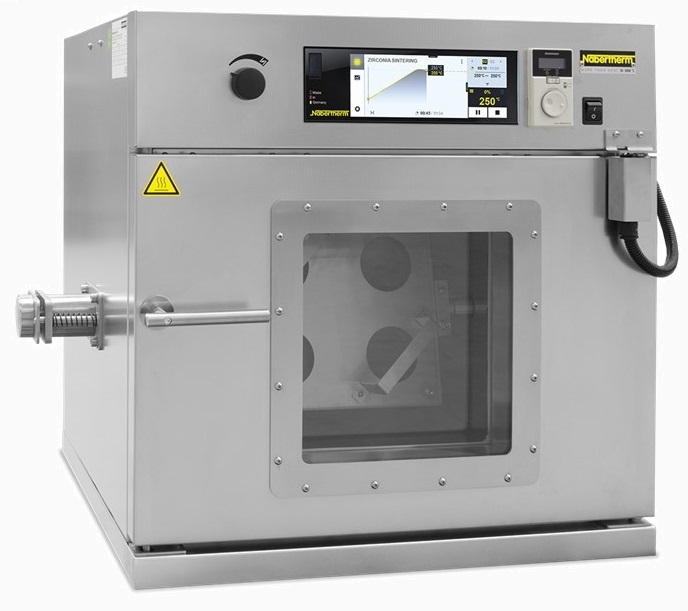

Forced Convection Chamber Furnaces – Tabletop Design (Electrically Heated)

These forced convection chamber furnaces are characterized by their excellent temperature uniformity. Due to the compact tabletop design, this series is ideal for laboratories or rooms with limited space.

Applications include preheating of components for shrink-fit processes, heat treatment of metals in air such as aging, stress relieving, soft annealing, or tempering, and heat treatment of glass.

🟨 Tmax 650 °C or 850 °C

🟨 Horizontal air circulation with stainless steel baffles for optimal distribution

🟨 Dual-shell stainless steel housing for low surface temp and high stability

🟨 Integrated control unit

🟨 Right-hinged swing door, usable up to 400 °C

🟨 Temperature uniformity up to ±6 °C (model NAT 15/65: ±5 °C)

🟨 High flow speeds for efficient air distribution

🟨 Air inlet at rear, adjustable exhaust and 15 mm port in ceiling (except NAT 15/65)

🟨 Over-temperature limiter with adjustable cutout

🟨 No RCF insulation – CLP-compliant

🟨 Controller B500/B510 (5 programs × 4 segments)

🟨 NTLog Basic – USB data recording

🟨 Freeware: NTEdit, NTGraph, MyNabertherm App for monitoring and documentation

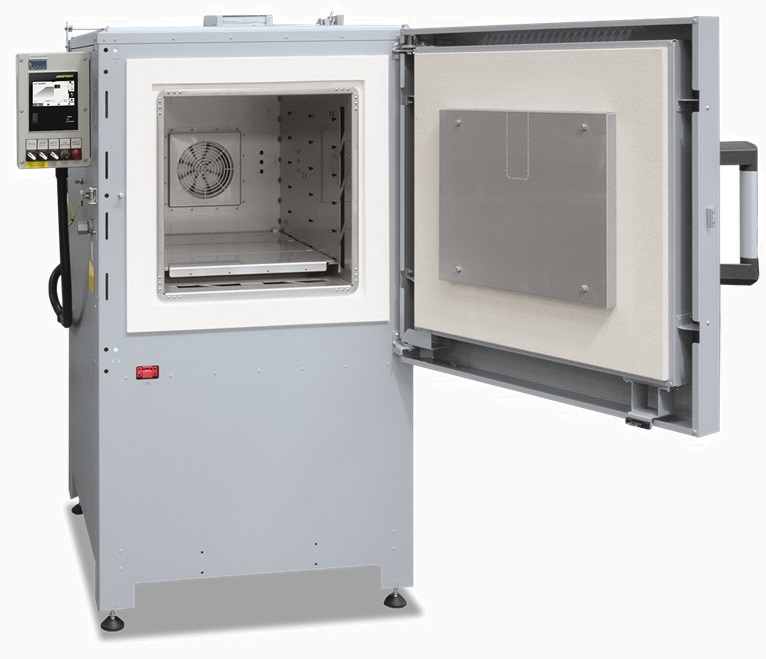

Forced Convection Chamber Furnaces up to 675 Lt (Electrically Heated)

The very good temperature uniformity of these chamber furnaces with air circulation ensures ideal process conditions for annealing, curing, solution annealing, artificial ageing, sintering of PTFE, preheating, soft annealing, and brazing. These forced convection chamber furnaces are equipped with a suitable annealing box for soft annealing of copper, tempering of titanium, and annealing of steel under non-flammable process gases. The modular design allows for adaptation to specific process requirements through the use of appropriate accessories.

🟨 Tmax 450 °C, 650 °C, or 850 °C

🟨 Horizontal air circulation with stainless steel baffles for optimal distribution

🟨 Swing door hinged on right side

🟨 Base frame included

🟨 Temperature uniformity up to ±4 °C (DIN 17052-1)

🟨 High flow speeds for optimal air distribution

🟨 Includes one frame sheet and rails for two trays

🟨 Over-temperature limiter with adjustable cutout

🟨 No RCF insulation – fully CLP-compliant

🟨 Controller B500 (5 programs × 4 segments)

🟨 Fan auto switch-off for 2 minutes after door opening

🟨 Side port and 3 mm thermocouple entry port

🟨 NTLog Basic – USB data logging

🟨 Freeware: NTEdit, NTGraph, and MyNabertherm App for monitoring

Ovens with Safety Technology

Ovens in the TR .. LS range with safety equipment based on EN 1539 Type A are suitable for drying charges containing solvents. With their compact design, these ovens can be easily integrated into a laboratory or production process. Exhaust gases escape through an outlet on the back of the oven and can then be extracted or treated.

🟨 Furnace technology based on ovens

🟨 For safety technology, see models NA 120/45 LS ff.

🟨 Tmax 260 °C

🟨 Temperature uniformity ±8 K (DIN 17052-1, empty workspace)

🟨 No RCF insulation – fully CLP-compliant

🟨 Defined application within operating instructions

🟨 Controller B510 (5 programs × 4 segments)

🟨 NTLog Basic – USB data recording

🟨 Freeware: NTEdit, NTGraph, and MyNabertherm App for monitoring and documentation

Forced Convection Chamber Furnaces up to 500 Liter Safety Technology

Due to their very good temperature uniformity, these chamber furnaces with air circulation are especially suitable for processes such as drying paints, components with residues of flammable cleaning agents, or the evaporation of solvents bound in the components.

🟨 Design based on forced convection chamber furnaces

🟨 High-powered heating to maintain required air exchange rates

🟨 Powerful exhaust air fan ensures underpressure in furnace

🟨 Monitored air circulation and exhaust air

🟨 Visual and audible malfunction signals

🟨 Over-temperature limiter with manual reset for furnace/load protection

🟨 No RCF insulation – fully CLP-compliant

🟨 Defined application within operating instructions

🟨 Touch controller P570 (50 programs × 40 segments)

🟨 NTLog Basic – USB data recording

🟨 Freeware: NTEdit, NTGraph, and MyNabertherm App