Linseis – Dilatometer

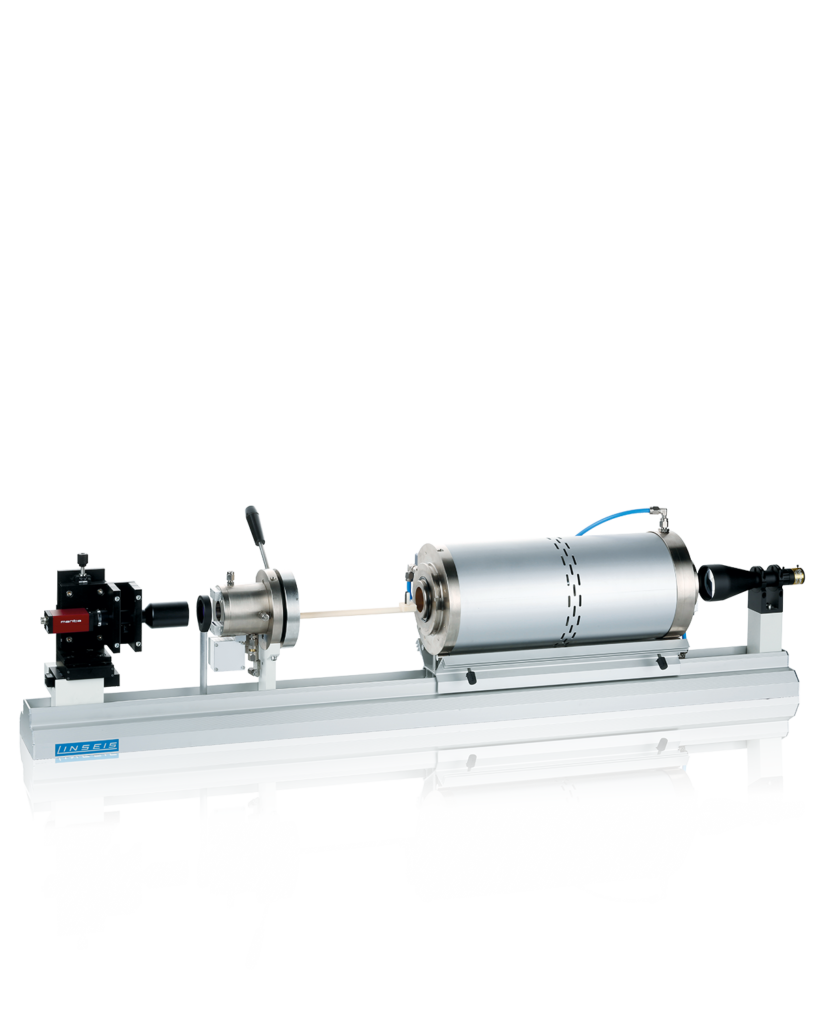

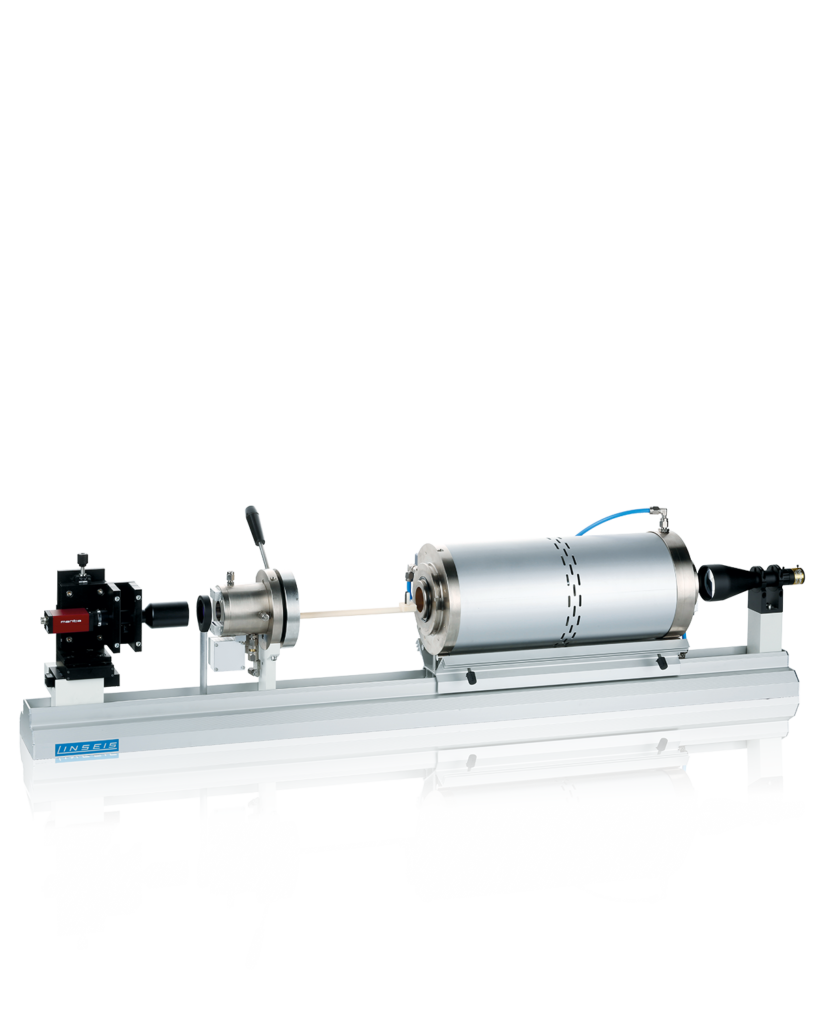

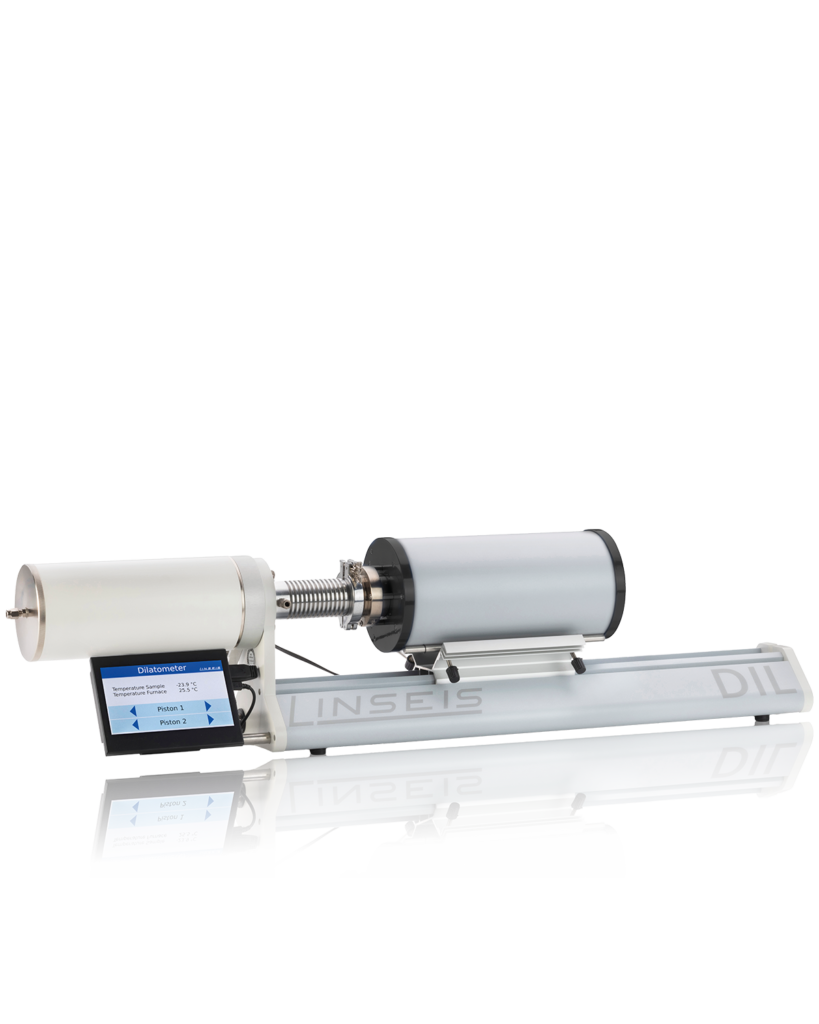

Linseis offers a range of high-precision dilatometers used for thermal expansion measurements in materials science. Their products include single, dual, and differential push-rod dilatometers, as well as optical and horizontal models, catering to diverse applications like R&D, quality control, and industrial processes. These instruments provide accurate thermal analysis for solids, liquids, and powders, supporting temperature ranges from cryogenic to over 2800°C. Options for customization and integration with advanced software enhance their functionality for demanding research needs.

Dilatometry - Expansion measurement - DIL

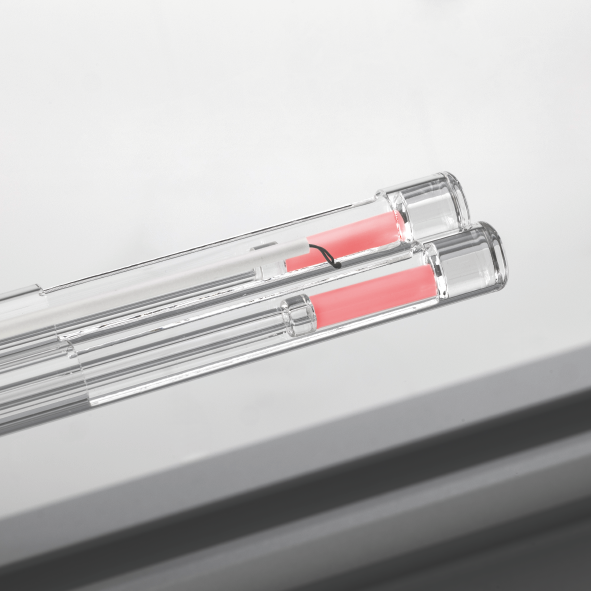

Measuring Principle

Linseis dilatometers offer maximum precision and enable automatic length change measurement of solids, powder pastes and liquids.

All Linseis dilatometers comply with international standards such as ASTM E831, ASTM D696, ISO 11358, ISO/DIS 9924, ASTM E1131, ASTM D3850, ASTM D6375, ASTM D6370, ASTM E2550 and ASTM D3175.

➡️ Measured variables and applications:

- Determination of the coefficient of thermal expansion (CTE)

- Linear thermal expansion (ΔL)

- Sintering temperatures and sintering stages

- Determination of the glass transition (Tg)

- Phase transitions

- Optimization of firing processes

- Volume changes

- Rate-controlled sintering (RCS)

- Decomposition

- Density change

Linseis Dilatometer Series

Horizontal vs. vertical structure

Horizontal alignment

- Simple and robust design at a moderate price

- Perfect choice for the medium temperature range

- Simple sample handling

- Customized dilatometers available for large samples

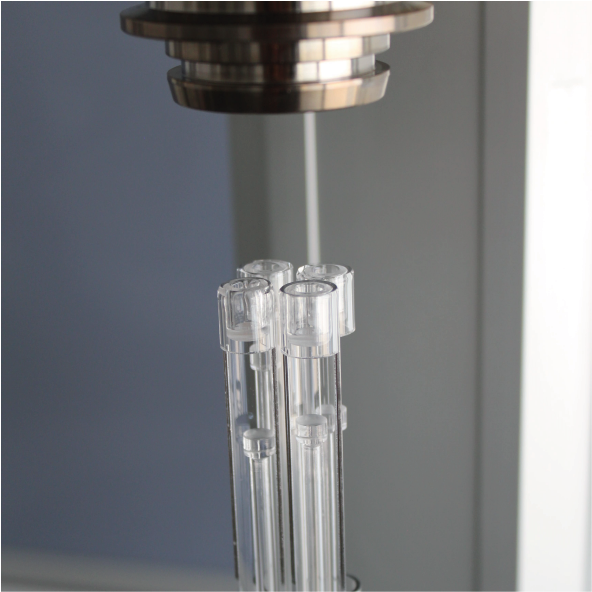

Vertical alignment

- Zero friction design (the sample is only in contact with the end stop and the push rod)

- Arrangement of several ovens (up to three ovens)

- to cover the entire temperature range from -180 to 2800°C, particularly ideal for low and very high temperatures

- to increase throughput (hot oven can be started up automatically to switch to a new cold oven and start a new measurement)

- perfect for measurements at low temperatures (oven below – measuring compartment above) to ensure access to the gas, cold air (falling downwards) below the sensor area

- perfect for high temperature measurements (oven above – measuring chamber below) to ensure access to the gas, hot air (flows upwards) above the sensor chamber

- low space requirement and low demands on the laboratory space

- available as single, differential/double and quattro arrangement (1, 2 or 4 samples simultaneously)

IDEAL FOR

Linseis dilatometers are ideal for:

- Thermal Expansion Analysis: Measuring thermal behavior in materials.

- Materials Science Applications: Studying ceramics, polymers, metals, and composites.

- Research & Development: Supporting high-precision experimental studies.

- Quality Control: Ensuring material consistency and performance.

- Industrial Use: Suitable for production and process optimization.

- Broad Temperature Ranges: Operating from cryogenic levels to over 2800°C.

- Diverse Material Forms: Analyzing solids, liquids, and powders.