Linseis | Gas Analysis (EGA)

Linseis Gas Analysis (EGA) is a technique used to analyze the composition of gases released during thermal processes, such as heating or decomposition of materials. It measures the quantity and types of gases emitted at different temperatures, providing insights into material behavior, chemical reactions, and stability.

LINSEIS | Gas Analysis (EGA)

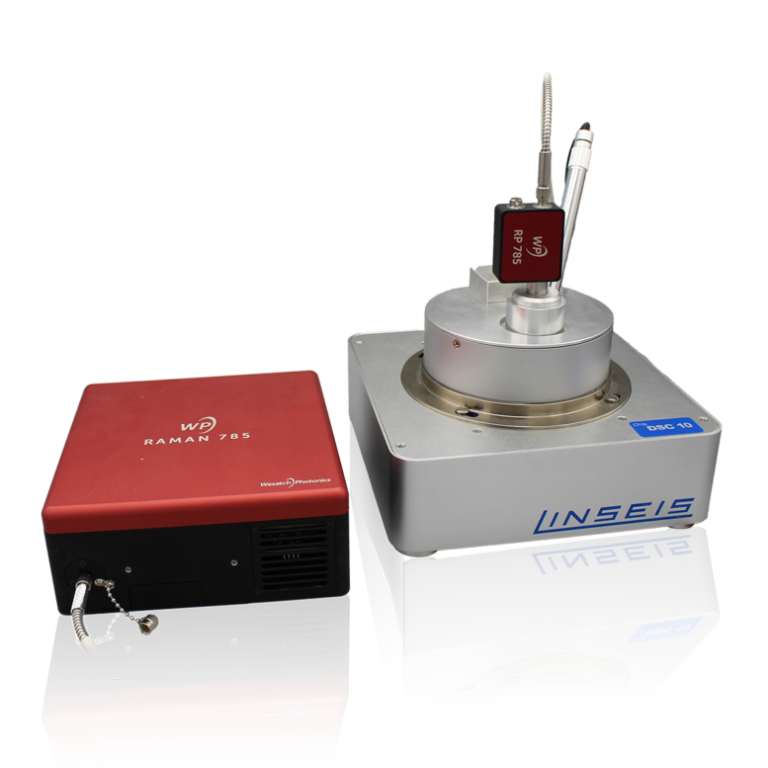

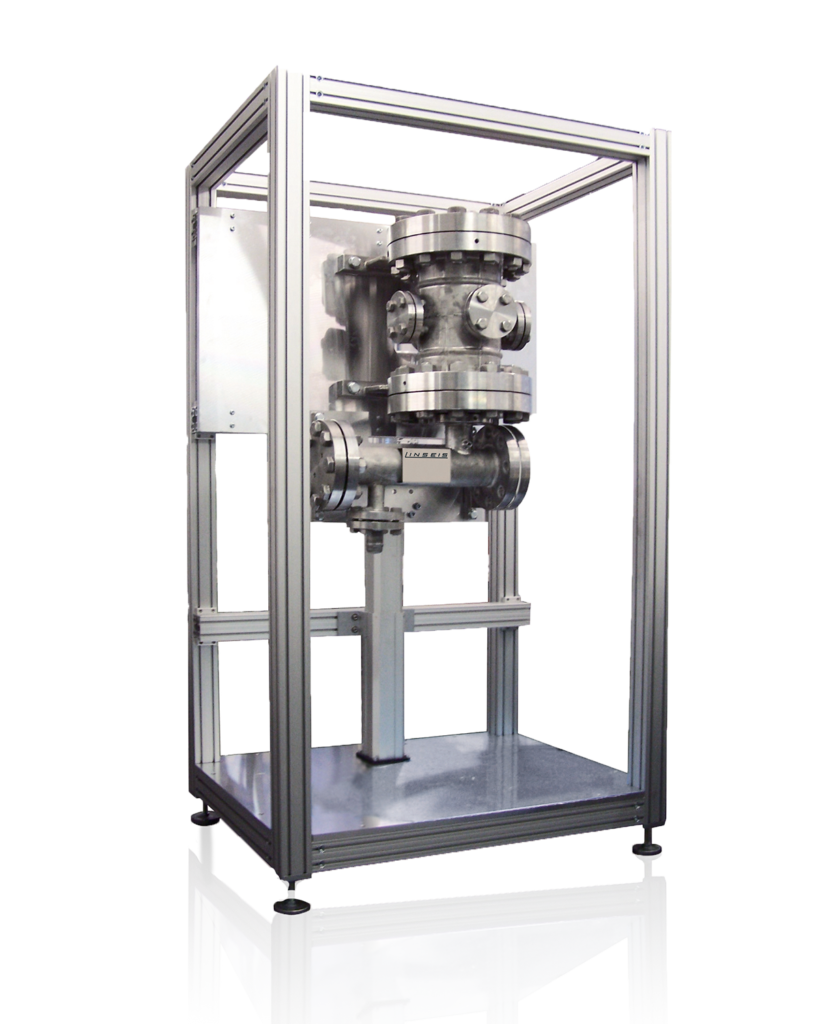

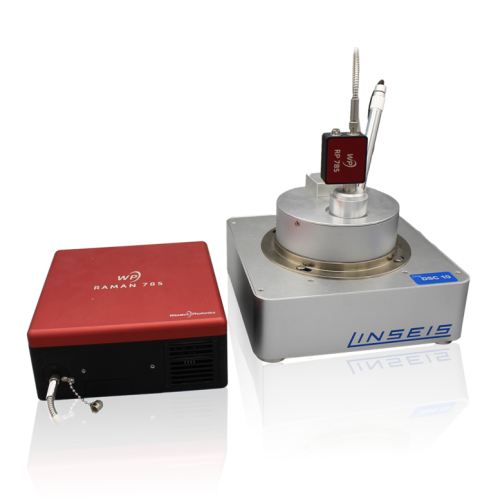

By coupling the thermal analyzer (for example a thermobalance TGA or Simultaneous Thermal Analyzer STA (TGA+DSC)) with the fast quadrupole mass spectrometer (QMS) or FTIR spectrometer (Fourier Tansform Infrared), it is possible to detect the gas separation and identify the separated components in exact temporal correlation with the other thermal analysis signals.

With the unique pulse analysis, even a quantitative gas analysis – both with QMS and FTIR – can be achieved.

Thanks to these couplings, Linseis can offer extremely high-performance solutions for thermal analysis, including residual gas analysis.

Linseis EGA Devices

Typical couplings in simultaneous analysis:

- TG-DSC-MS (Thermogravimetry, Differential Scanning Calorimetry, mass spectrometer)

- TGA-MS (thermobalance coupled with mass spectrometer)

- TG-DSC-GC/MS (thermogravimetry, differential scanning calorimetry, gas chromatography / mass spectrometer)

The thermal analyzer can be coupled to the spectrometer/chromatograph in various ways:

- Heated transfer capillary (FTIR, GCMS, GC, MS)

- Sniffer coupling (GCMS, GC, MS)

- Optical in-situ observation (ELIF)

Analytical techniques for coupling with thermal analyzers Coupling can be performed using various gas analysis methods:

- FT-IR spectroscopy

- Quadrupole mass spectrometry (QMS)

- ELIF spectroscopy (excimer laser-induced fragmentation fluorescence)

- Gas chromatography

Downloads

IDEAL FOR

Linseis EGA (Evolved Gas Analysis) systems are particularly ideal for:

- Thermal Decomposition Studies: Linseis EGA is well-suited for analyzing the gases released from materials during thermal decomposition, providing insights into the material’s stability and behavior at different temperatures.

- Polymer and Material Characterization: It is used for studying polymers, composites, and other materials to identify and quantify the gases released during heating or degradation, helping in material selection and development.

- Quality Control and Process Optimization: Linseis EGA is ideal for monitoring the composition of materials in industrial processes, ensuring product consistency and optimizing production by analyzing gas evolution patterns.

- Environmental Impact Analysis: It helps detect and quantify harmful gases, such as VOCs or CO2, which may be released from materials during thermal processes, assisting in environmental monitoring and regulatory compliance.

- Catalysis and Reaction Monitoring: Linseis EGA is ideal for analyzing gases produced during catalytic reactions or chemical processes, aiding researchers in understanding reaction mechanisms, reaction kinetics, and catalyst efficiency.

- Research in Material Science: It is a valuable tool for studying the thermal properties of materials, including ceramics, metals, and composites, by identifying the gases released as they undergo thermal treatments.

- Pharmaceuticals and Active Ingredients: Linseis EGA is used in the pharmaceutical industry to study the release of gases during thermal processes, such as the degradation or sublimation of active pharmaceutical ingredients (APIs).

FEATURES

MODEL PFEIFFER THERMOSTAR |

EGA – QMS (EGA COUPLING / GAS ANALYSIS) |

|---|---|

| Mass range: | 100/200/300 AMU |

| Detector: | Faraday and SEV (Channeltron) |

| Ion source: | Electron impact, energy 100 eV |

| Vacuum system: | Turbomolecular pump and diaphragm pump (oil-free vacuum) |

| Heating: | Adapter head, capillary and QMS |

| Coupling with: | DSC, TGA, STA via heatable adapter accessories |

MODEL |

FTIR – GAS ANALYSIS (EGA COUPLING) |

|---|---|

| Wavenumber range: | 7500 cm-1 … 370 cm-1 |

| Resolution: | 1 cm-1 |

| Heating: | Transfer line and adapter |

| Transfer line material: | PTFE (interchangeable) |

| Couplings: | DIL, TMA, STA, TGA, DTA, DSC |