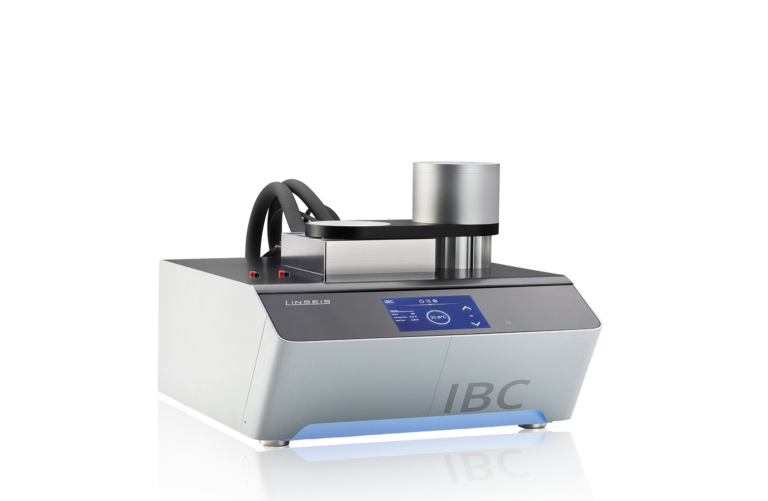

Linseis – Isothermal Battery Calorimeter (IBC)

Battery calorimeters measure heat development in batteries. LINSEIS offers modular IBCs for research and quality control.

LINSEIS | Isothermal Battery Calorimeter (IBC)

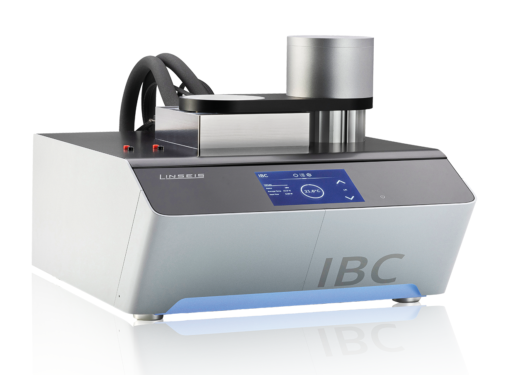

A battery calorimeter (LINSEIS IBC – Isothermal Battery Calorimeter) is a device for measuring the heat generated by a battery during charging and discharging.

This measurement is referred to as “heat of reaction” and is an important indicator of a battery’s performance.

The heat of reaction is the difference between the enthalpy (heat content) of the reactants and the products of a chemical reaction.

Battery calorimeters are used in research and development to evaluate new battery chemistries and optimize the design of existing batteries.

They are also used in the manufacturing process to ensure that the batteries meet performance and safety standards.

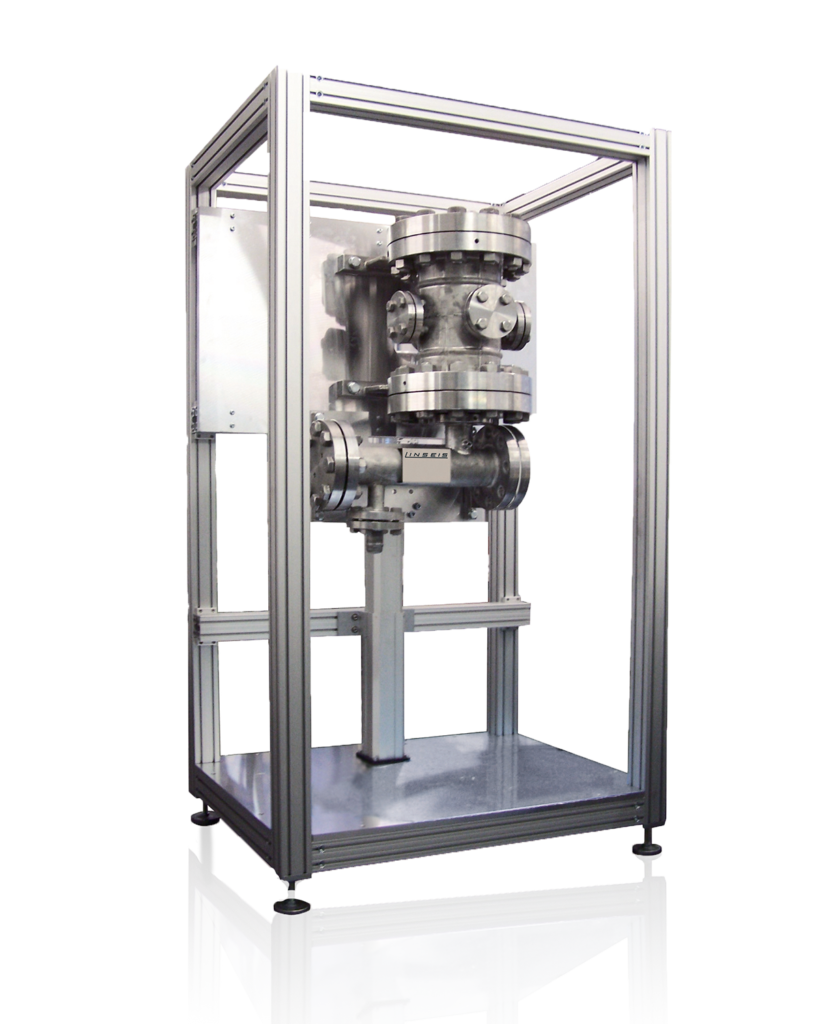

LINSEIS offers a modular Isothermal Battery Calorimeter (IBC) for the thermal monitoring of batteries.

It consists of a variable number of almost identical components and enables the investigation of a wide range of battery cell sizes.

The geometry of the modules is also easily scalable.

IDEAL FOR

These devices are particularly important for the development of new battery types, such as lithium-ion batteries, where thermal stability and safety are of paramount importance.

They are also used for quality control and performance testing of batteries.

Areas of application:

Thermal analysis and safety: By analyzing heat development under different operating conditions, battery calorimeters help to identify and prevent potential safety risks such as thermal runaway.

This is crucial for the safety of end-user products.

Optimizing battery performance: By accurately measuring heat generation, the internal chemistry and design of the battery can be optimized, resulting in higher energy density, better charging capacity and a longer service life.

Research and development: Battery calorimeters are used in research and development laboratories to test and evaluate new materials and technologies.

The knowledge gained is essential for progress in battery technology.

Linseis IBC gives the ability to deeply investigate batteries

- Under different temperature conditions

- For aging behavior

- For efficiency level of cell and electronics

- For various battery types

- For various cell formats (pouch, coin, round, boxed …)

- For phase changes during usage

FEATURES

MODEL |

IBC |

|---|---|

| Measuring cell | |

| Measuring plate | 80 x 80 mm 250 x 250 mm 400 x 250 mm others on request |

| Sample height | up to 100 mm |

| Measuring range | max. 10W (for 80 x 80 mm measuring plate) |

| Calorimetric resolution | 0,1 mW |

| Calorimetric accuracy | 0,5 mW |

| Temperature dimensional resolution | 8 sensors (for 80 x 80 mm measuring plate) |

| Additional temperature sensors | Available on request |

| Heat flux dimensional resolution | 8 sensors (for 80 x 80 mm measuring plate) |

| Cell adapter | Available for 14500, 18650, coin cell, on request |

| Sampling rate | Up to 10 Hz |

| Calibration | Integrated automatic calibration procedure, calibration heater |

| Noise | 0,25 mW |

| Environmental conditions / temperature options | |

| Temperature range | -40 °C to 140 °C |

| Temperature stability | 0,01 K |

| Temperature resolution | 0,0001 °C |

| Temperature accuracy | 0,001 °C |

| Electrical specification | |

| Power supply | AC 230 V / 50 Hz |

| Maximum power consumption | 120 W (main unit) |

| Display | Yes |

| Charging current | Depending on customer selection |

| Charging voltage | Depending on customer selection |

| Discharge voltage | Depending on customer selection |

| Battery charges | On request |

| Laboratory power supply | On request |

| Software functions | Linsels Platinum Software (free of charge) |

| Software functions | Automatic calibration mode, heat flow correction, powerful evaluation software with calorimetric tools |