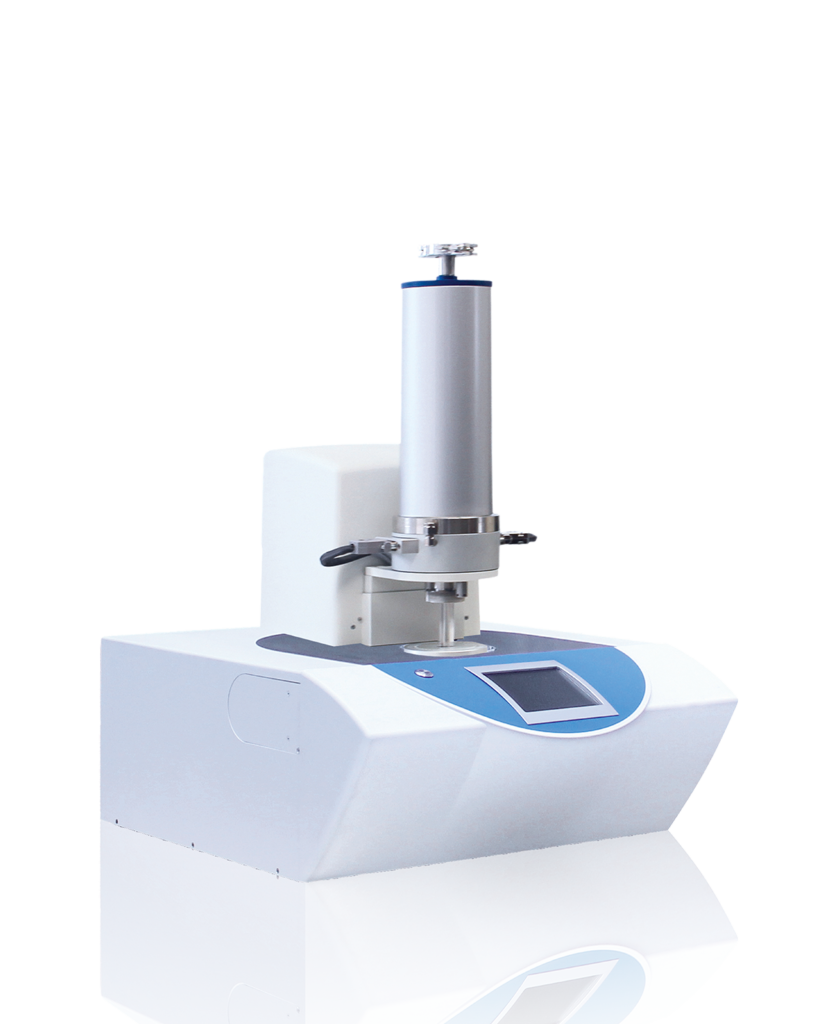

Linseis | Thermomechanical analysis (TMA)

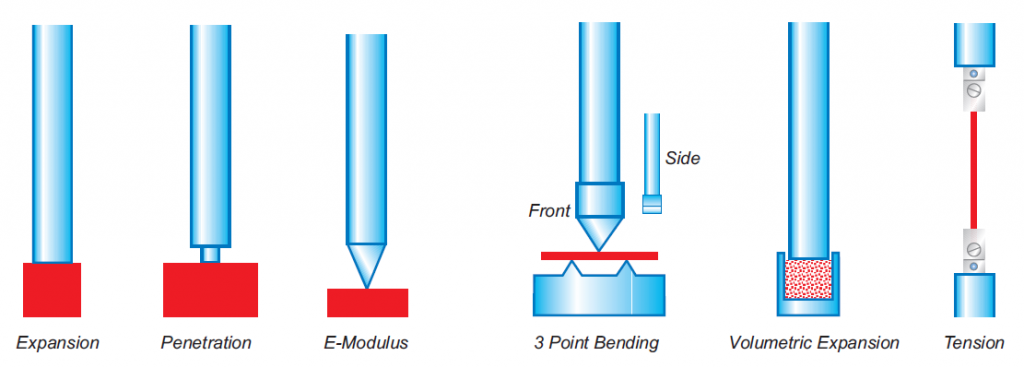

With the thermomechanical analysis (TMA) the change in sample geometry is measured with additional sample loading via the temperature. Static tests include: Expansion, penetration, tensile and compression tests as well as 3-point bending.

LINSEIS - Thermomechanical Analysis (TMA)

By applying an oscillating force to the sample, the dynamic mechanical analysis (dynamic TMA) records its frequency and temperature dependence as well as the viscoelastic properties and thus determines the modulus of elasticity and the damping values.

All TMA devices operate in accordance with the following national and international standards (DIN 51 005, ASTM D 3386, ASTM E 831, ASTM D 696, ISO 11359 – Part 1 to 3).

The Concept

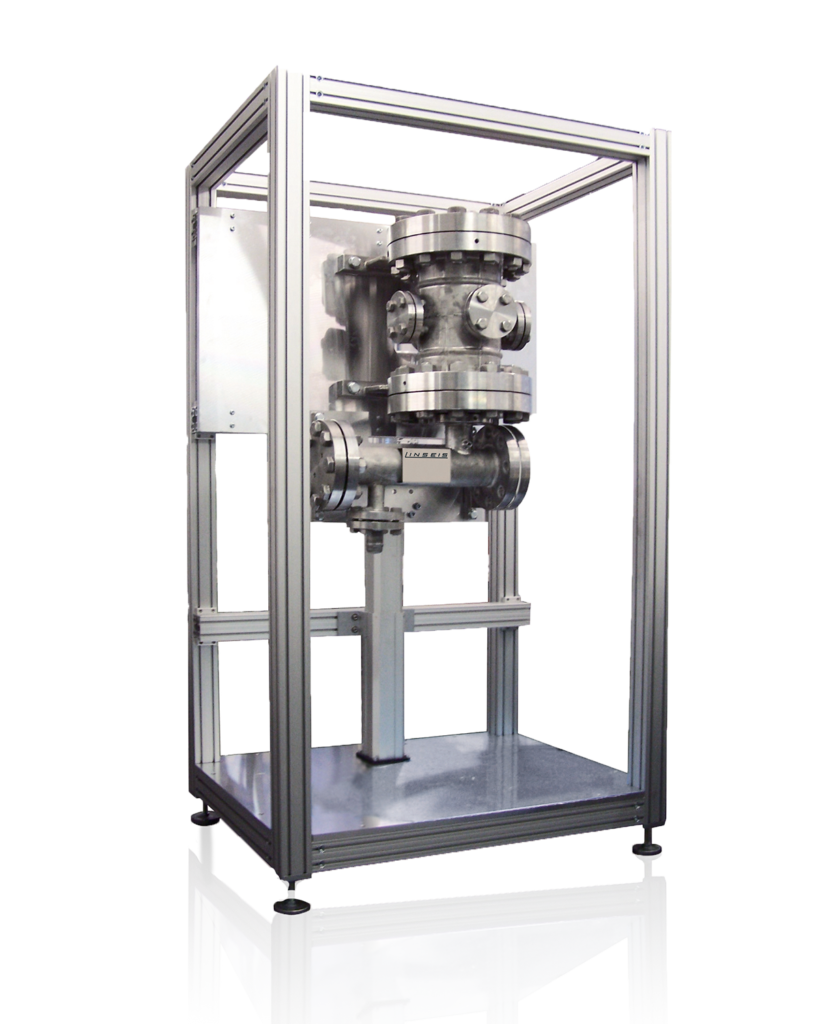

Measuring chamber: The easily accessible chamber is located in the middle of the oven.

Both the temperature and the atmosphere can be controlled separately.

An optional mass flow controller for regulating a purge gas is also available.

The vacuum-tight cell enables measurement under defined atmospheres.

This means that samples that are sensitive to oxidation can also be measured perfectly.

Oven: A range of robust and reliable ovens is available for the TMA Platinum series.

The individual design enables extremely fast heat-up and cool-down times, as well as excellent temperature control over the entire measuring range

Linseis TMA measuring devices

Downloads

IDEAL FOR

Linseis TMA is ideal for the study of thermal expansion, phase transitions, glass transition temperatures, creep behavior, and more, providing essential insights for material development, quality control, and research applications.

- Determining thermal expansion: It accurately measures the coefficient of thermal expansion (CTE), which describes how a material expands or contracts with temperature changes. This is critical for materials used in applications where thermal cycling or temperature-induced dimensional stability is important (e.g., electronics, automotive, aerospace).

- Glass transition temperature (Tg) analysis: TMA can be used to identify the glass transition temperature of polymers, providing insights into their behavior when transitioning from a hard and brittle state to a more flexible state.

- Creep and stress relaxation studies: TMA can measure how materials deform under a constant load at elevated temperatures. This is especially useful for understanding long-term material performance under mechanical stress.

- Viscoelastic behavior analysis: It helps in studying the balance between elasticity and viscosity in polymers and other materials, which is important for predicting performance in various industrial applications.

- Phase transitions: The instrument can be used to analyze phase transitions in materials, such as melting, crystallization, or solid-state transitions, providing valuable data for material selection and processing.

- Material characterization: TMA by Linseis can characterize the thermal and mechanical properties of a wide range of materials, including metals, polymers, ceramics, composites, and more, under different conditions.

FEATURES

MODEL |

TMA PT 1000 |

|---|---|

| Temperature range: | RT up to 1000°C -150°C optional |

| Sample size: | 30 mm |

| Force: | up to 1 or 5.7 N |

| Frequency: | 1 Hz |

| Resolution: | 0.125 nm |

| Atmospheres: | red., inert, oxid., static/dyn. |

| Electronics: | Integrated |

| Interface: | USB |

MODEL |

TMA PT 1000 EM |

|---|---|

| Temperature range: | -150 up to 1000°C -260 up to +220°C |

| Sample size: | 30 mm |

| Force: | up to 1 / 5.7 / 20 N |

| Frequency: | – |

| Resolution: | 0.125 nm |

| Atmospheres: | red., inert, oxid., static/dyn. |

| Electronics: | Integrated |

| Interface: | USB |

MODEL |

TMA PT1600 |

|---|---|

| Temperature range: | RT up to 1600°C |

| Sample size: | 30 mm |

| Contact pressure: | up to 1 or 5.7 N |

| Frequency: | 1 or 5 Hz |

| Resolution: | 0.125 nm |

| Atmosphere: | reducing, inert, oxidising static / dynamic |

| Electronics: | Integrated |

| Interface: | USB |